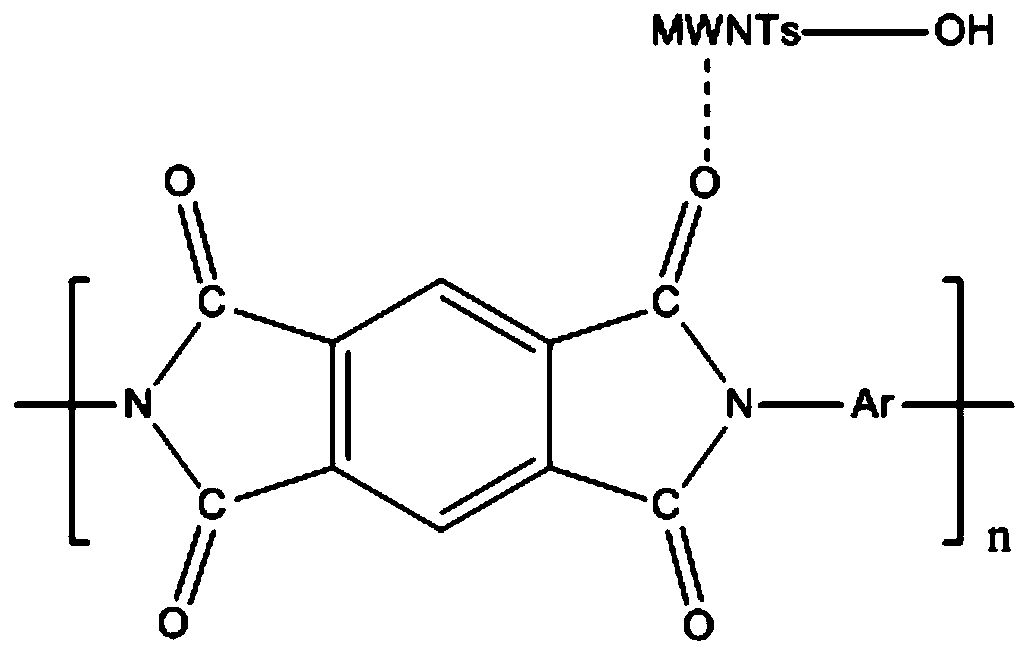

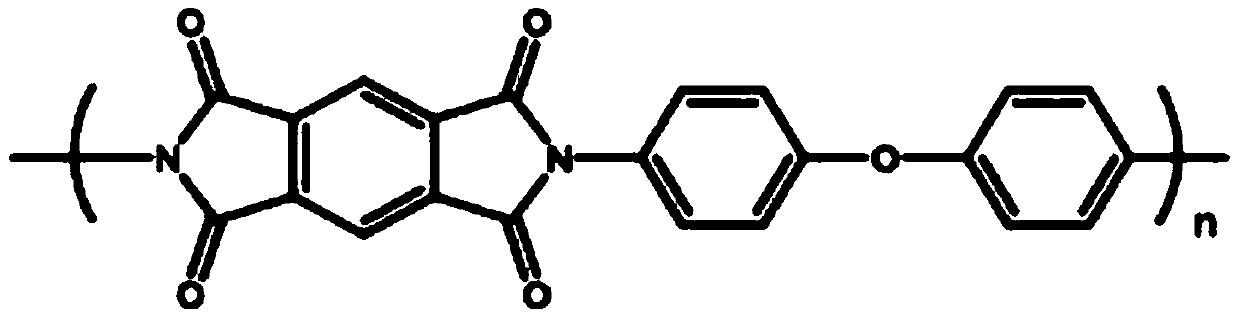

Method for preparing polyimide film with surface modified by MWNTs (multi-walled carbon nanotubes)

A polyimide film and surface modification technology, which is applied in the field of polyimide film preparation of surface modified MWNTs, can solve the problem of PI film tensile strength reduction, failure to improve the performance of composite materials, and lack of organic functional groups, etc. problem, achieve results with reliable ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

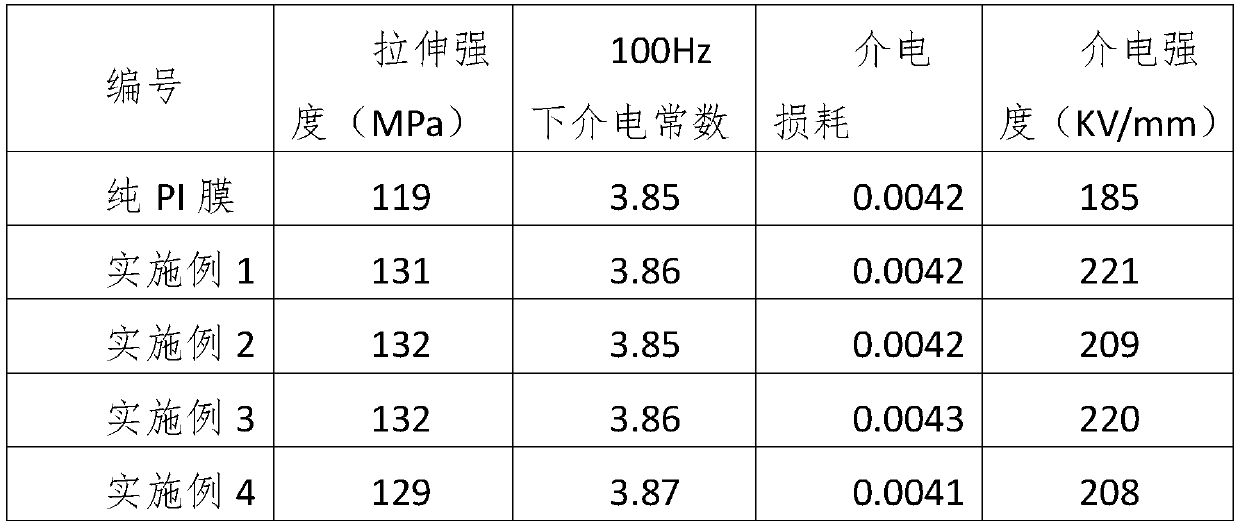

Embodiment 1

[0027] A method for preparing a polyimide membrane of surface-modified MWNTs, comprising the following steps:

[0028] 1) Drying of raw materials: grind pyromellitic dianhydride, dry at 160°C for 5 hours, grind 4,4'-diaminodiphenyl ether, dry at 110°C for 5 hours, add sodium hydroxide to N,N-dimethylacetamide , after standing for 20min, distill under reduced pressure, remove 2ml of the former fraction and collect;

[0029] 2) MWNTs pretreatment: add water to MWNTs, the volume of water is 1 / 2 of the volume of MWNTs, 30 ° C for 1 h, then filter with suction, wash with N,N-dimethylacetamide 3 times, dry at 200 ° C for 3 h, grind to crush, to get;

[0030] 3) Surface treatment of MWNTs: Weigh FeSO 4 ·7H 2 Dissolve O in water, adjust the pH to 3 with 1mol / L dilute sulfuric acid, add the MWNTs pretreated in step 2) and mix well, add dropwise H 2 o 2 After 20 minutes, the dropwise addition is completed, continue to react for 1.5h, filter with suction, wash the solid matter with ...

Embodiment 2

[0034] A method for preparing a polyimide membrane of surface-modified MWNTs, comprising the following steps:

[0035] 1) Drying of raw materials: grind pyromellitic dianhydride, dry at 160°C for 5 hours, grind 4,4'-diaminodiphenyl ether, dry at 110°C for 5 hours, add sodium hydroxide to N,N-dimethylacetamide , after standing for 20min, distill under reduced pressure, remove 2ml of the former fraction and collect;

[0036] 2) MWNTs pretreatment: add water to MWNTs, the volume of water is 1 / 3 of the volume of MWNTs, 20 ° C for 1 h, then filter with suction, wash with N,N-dimethylacetamide 3 times, and dry at 200 ° C for 3-5 h , ground and pulverized to obtain;

[0037] 3) Surface treatment of MWNTs: Weigh FeSO 4 ·7H 2 Dissolve O in water, adjust the pH to 3 with 1mol / L dilute sulfuric acid, add the MWNTs pretreated in step 2) and mix well, add dropwise H 2 o 2 After 25min, the dropwise addition is completed, continue to react for 1.5h, filter with suction, wash the solid m...

Embodiment 3

[0041] A method for preparing a polyimide membrane of surface-modified MWNTs, comprising the following steps:

[0042] 1) Drying of raw materials: grind pyromellitic dianhydride, dry at 160°C for 5 hours, grind 4,4'-diaminodiphenyl ether, dry at 110°C for 5 hours, add sodium hydroxide to N,N-dimethylacetamide , after standing for 20min, distill under reduced pressure, remove 2ml of the former fraction and collect;

[0043] 2) MWNTs pretreatment: add water to MWNTs, the volume of water is 1 / 2 of the volume of MWNTs, 25 ° C for 1 h, then filter with suction, wash 3 times with N,N-dimethylacetamide, and dry at 200 ° C for 3-5 h , ground and pulverized to obtain;

[0044] 3) Surface treatment of MWNTs: Weigh FeSO 4 ·7H 2 Dissolve O in water, adjust the pH to 3 with 1mol / L dilute sulfuric acid, add the MWNTs pretreated in step 2) and mix well, add dropwise H 2 o 2 After 25 minutes, the dropwise addition was completed, and the reaction was continued for 1.2 hours, filtered with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com