A kind of biaxially stretched polyketone co-extruded barrier film and preparation method thereof

A biaxially stretched, barrier film technology, applied in the field of food packaging materials, can solve the problems that cannot meet the requirements of high barrier film application field, biaxially stretched POK film does not have high barrier, etc., to reduce antibacterial ion transfer and improve sports ability , Improve the effect of barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

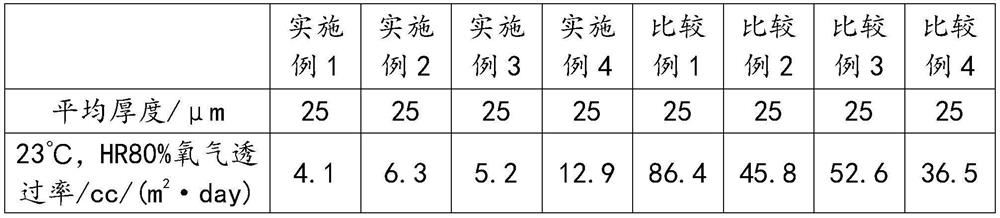

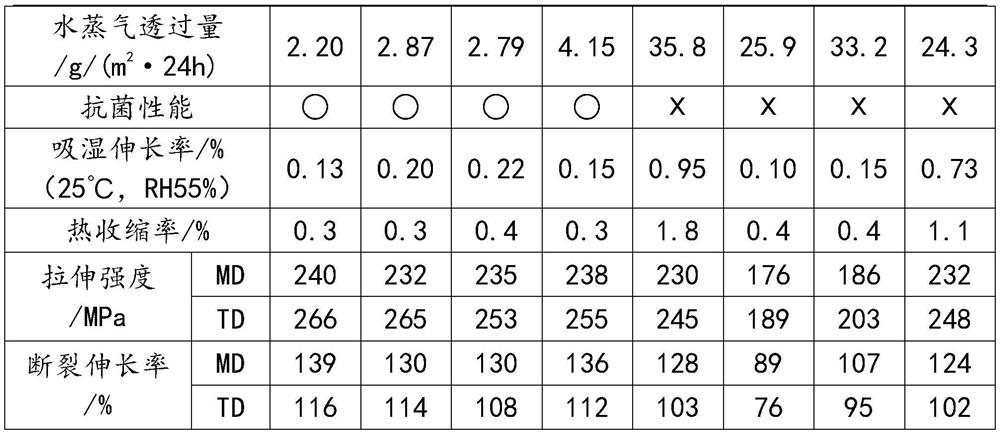

Examples

Embodiment 1

[0032] A biaxially oriented polyketone co-extruded barrier film, comprising five layers of co-extruded film, the film layer structure from the outside to the inside is a polyamide outer layer, a first polyketone composite material layer, a polyamide antibacterial core layer, and a second polyamide layer. Ketone composite material layer, polyamide inner surface layer;

[0033] The polyamide outer layer and the polyamide inner layer include the following components according to mass percentage: 99.2% of polyamide 6, 0.6% of silicon dioxide, and 0.2% of ethylene bisstearic acid amide.

[0034] The first polyketone composite material layer and the second polyketone composite material layer include the following components according to mass percentage: polyketone resin 62%, semi-aromatic polyamide MXD6 20%, PA-g-MHA 5%, polyacrylic acid 12% , magnesium stearate 1%.

[0035] The polyamide antibacterial core layer comprises the following components according to mass percentage: 82% ...

Embodiment 2

[0042] A biaxially oriented polyketone co-extruded barrier film, comprising five layers of co-extruded film, the film layer structure from the outside to the inside is a polyamide outer layer, a first polyketone composite material layer, a polyamide antibacterial core layer, and a second polyamide layer. Ketone composite material layer, polyamide inner surface layer;

[0043] The polyamide outer layer and the polyamide inner layer include the following components according to mass percentage: 98.5% of polyamide 6, 1% of silicon dioxide, and 0.5% of ethylene bisstearic acid amide.

[0044] The first polyketone composite material layer and the second polyketone composite material layer include the following components according to mass percentage: polyketone resin 45%, semi-aromatic polyamide MXD6 30%, PA-g-MHA 8%, polyacrylic acid 15% , magnesium stearate 2%.

[0045] The polyamide antibacterial core layer includes the following components according to mass percentage: 72% of po...

Embodiment 3

[0048] A biaxially oriented polyketone co-extruded barrier film, comprising five layers of co-extruded film, the film layer structure from the outside to the inside is a polyamide outer layer, a first polyketone composite material layer, a polyamide antibacterial core layer, and a second polyamide layer. Ketone composite material layer, polyamide inner surface layer;

[0049] The polyamide outer layer and the polyamide inner layer include the following components according to mass percentage: 99.5% of polyamide 6, 0.4% of silicon dioxide, and 0.1% of ethylene bisstearic acid amide.

[0050] The first polyketone composite material layer and the second polyketone composite material layer include the following components according to mass percentage: polyketone resin 71.5%, semi-aromatic polyamide MXD6 15%, PA-g-MHA 3%, polyacrylic acid 10% , magnesium stearate 0.5%.

[0051] The polyamide antibacterial core layer comprises the following components according to mass percentage: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com