Semiconductor device, manufacturing method and mask

A manufacturing method and semiconductor technology, applied in semiconductor devices, electrical solid devices, electrical components, etc., can solve the problems of etching load effect, affecting device performance, and deterioration of the uniformity of key dimensions of word lines, etc., to improve uniformity, The effect of improving device performance and reducing the effect of etching load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

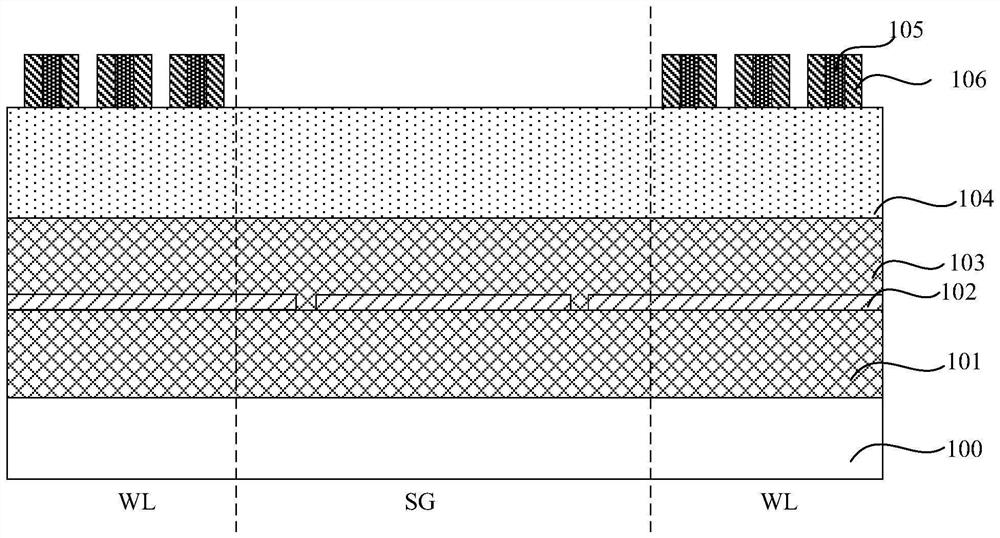

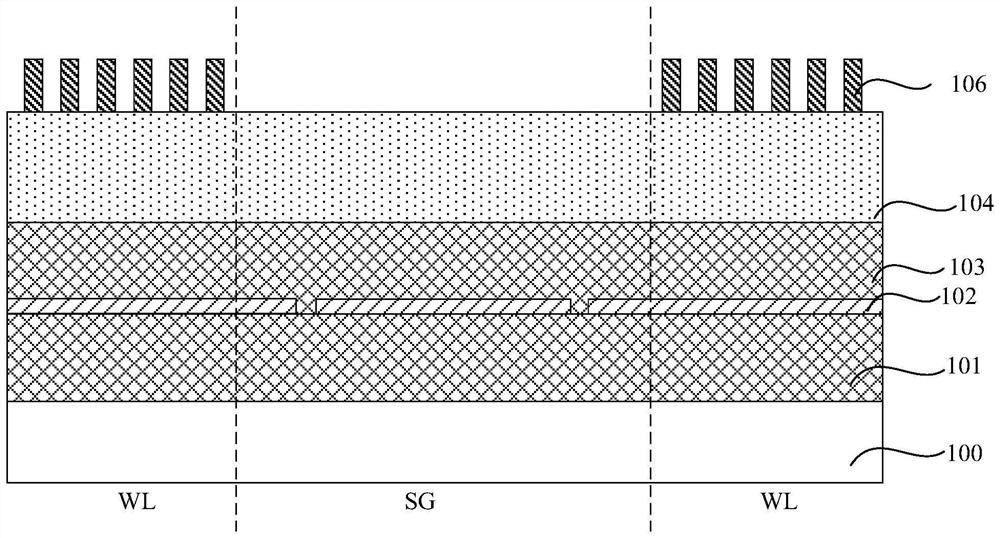

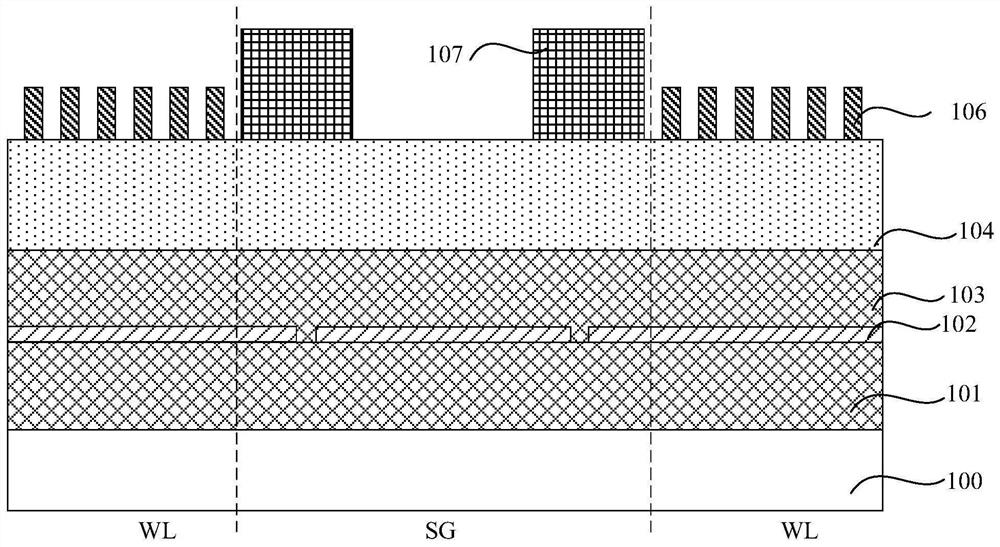

[0042] In the following, a NAND flash memory device is taken as an example to describe in detail the adverse effects of the sparse / dense loading effect of the gate on the performance of the device. Such as Figure 1E As shown, a NAND flash memory device may include: a selection gate (SG, that is, the gate of the selection transistor, the source or drain of the selection transistor is connected to the bit line) 103b and arranged outside the selection gate (SG) 103b A plurality of word lines (WL) 103a, the selection gate 103b and the word line 103a are formed by connecting the control gate (Control Gate, CG) of the memory cell on the same active area, the selection gate (SG), the word line ( WL) are arranged in parallel, and a corresponding charge storage structure can be provided between each word line 103a and each active area (ACT), so as to provide a corresponding memory cell at each intersection of WL and active area (ACT). . Usually, the distribution of select gate 103b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com