VOCs gas cryogenic recovery device based on industrial waste cool

A recovery device and waste cooling technology, applied in the field of VOCs gas cryogenic recovery device, can solve the problems of incomplete recovery of VOCs gas and environmental protection of exhaust gas, etc., and achieve the effect of improving recovery rate and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

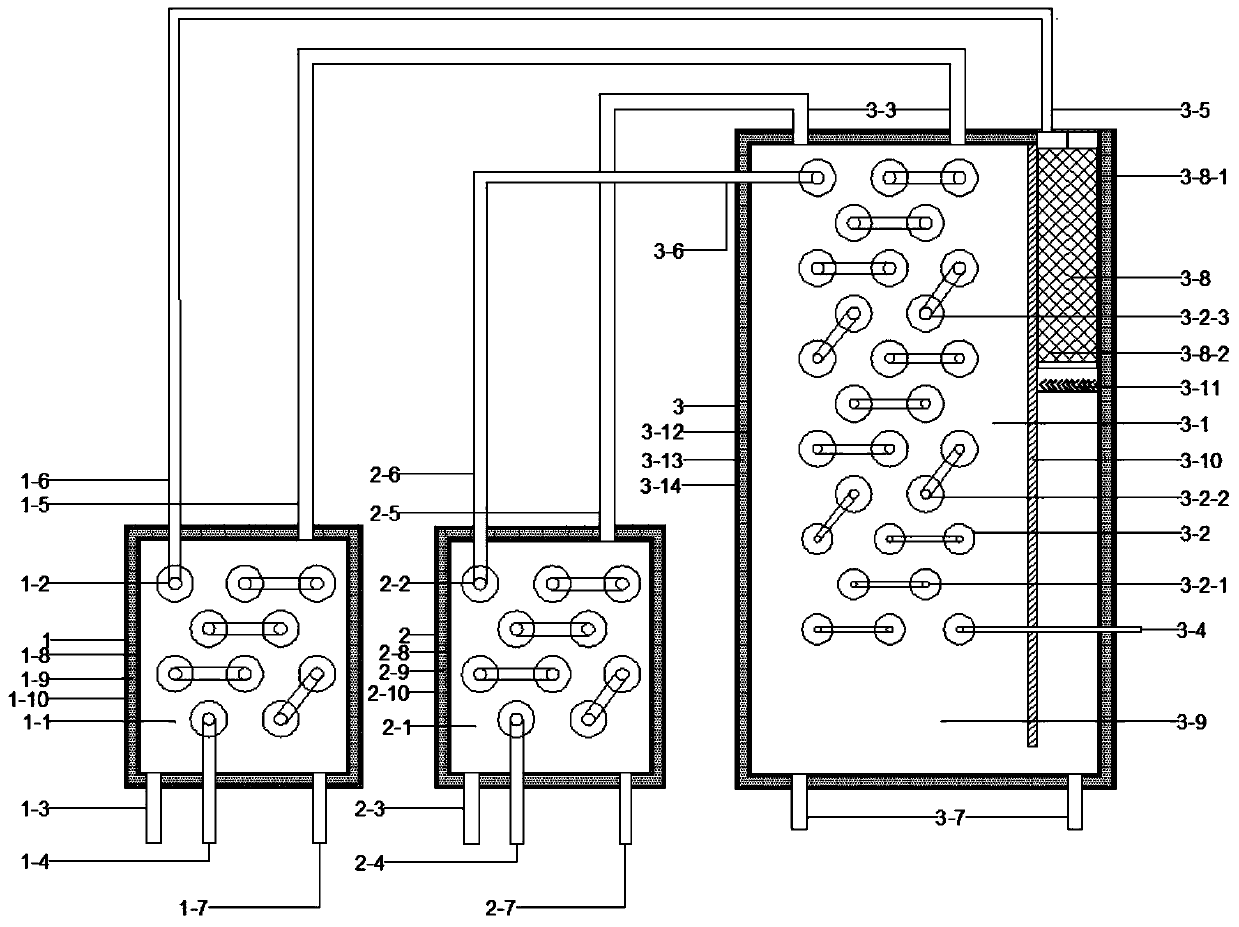

[0020] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so as to better understand the present invention.

[0021] The VOCs gas to be treated can be divided into two parallel streams and enter the primary cooler (1) and primary cooler (2) through the VOCs gas inlet (1-3) and (2-3) for dehydration. The cooling temperature of the cooler (2) is -20~0°C, the water flows out from the outlet of the primary cooler (1-7) and the outlet of the primary cooler (2-7), and the gas to be treated is discharged from the VOCs gas outlet after the dehydration is completed (1-5), (2-5) enter the cryocooler (3) to remove oil through the dehydration VOCs gas inlet (3-3). The dehydrated VOCs gas enters from the upper part (3-3) and flows downward, and the dehydrated VOCs gas is liquefied in the gas-liquid separation area (3-9). There are two oil discharge ports (3-7) at the bottom of the cryocooler (3) ), the liquefied VOCs flow o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap