Portable accurate grinding and sampling device for concrete surface layer

A kind of sampling equipment and concrete technology, applied in the direction of sampling devices, etc., can solve the problems of inability to accurately control the demand for sampling volume, heavy equipment, etc., and achieve the effect of novel structural design, convenient and fast processing, and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

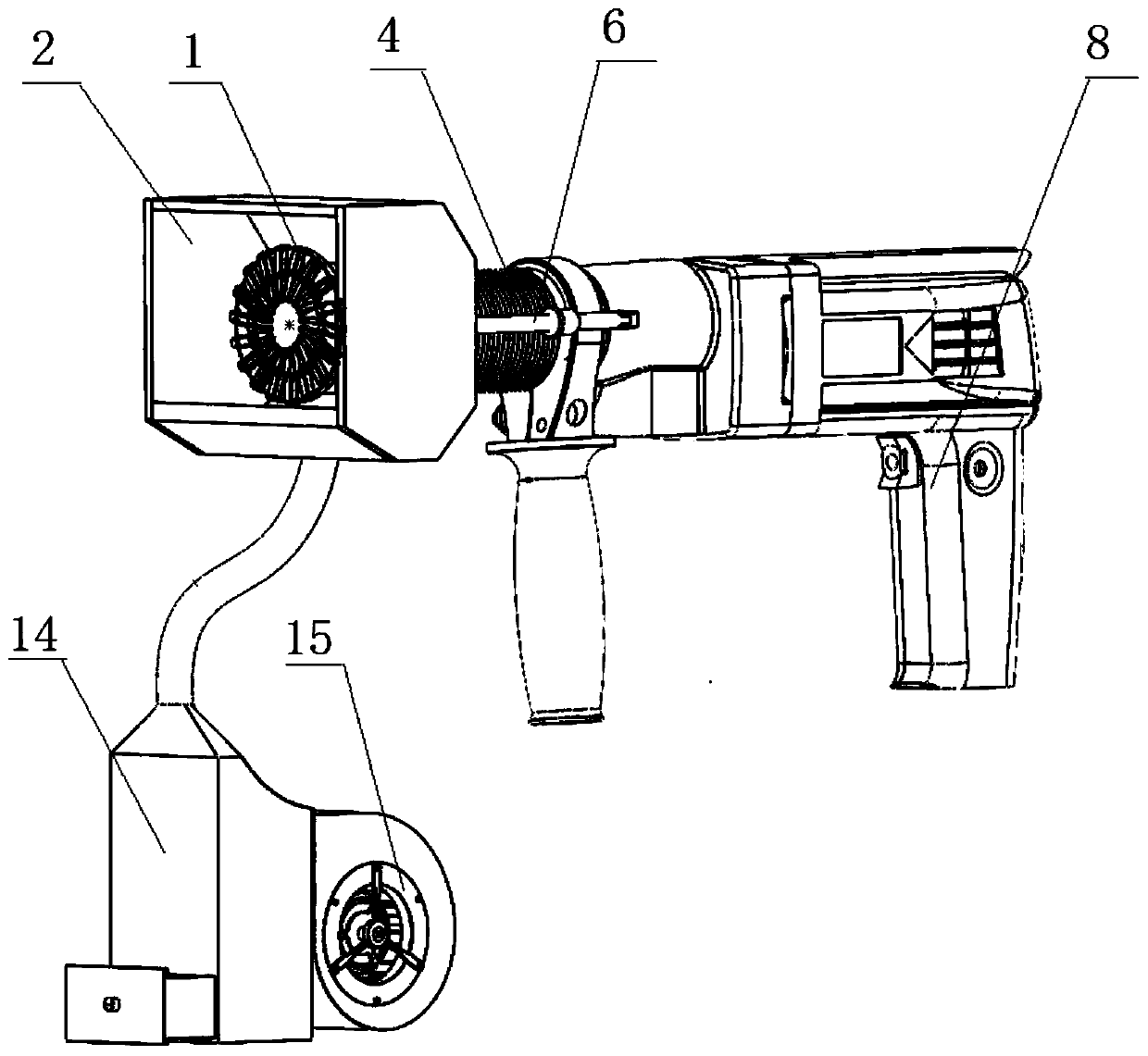

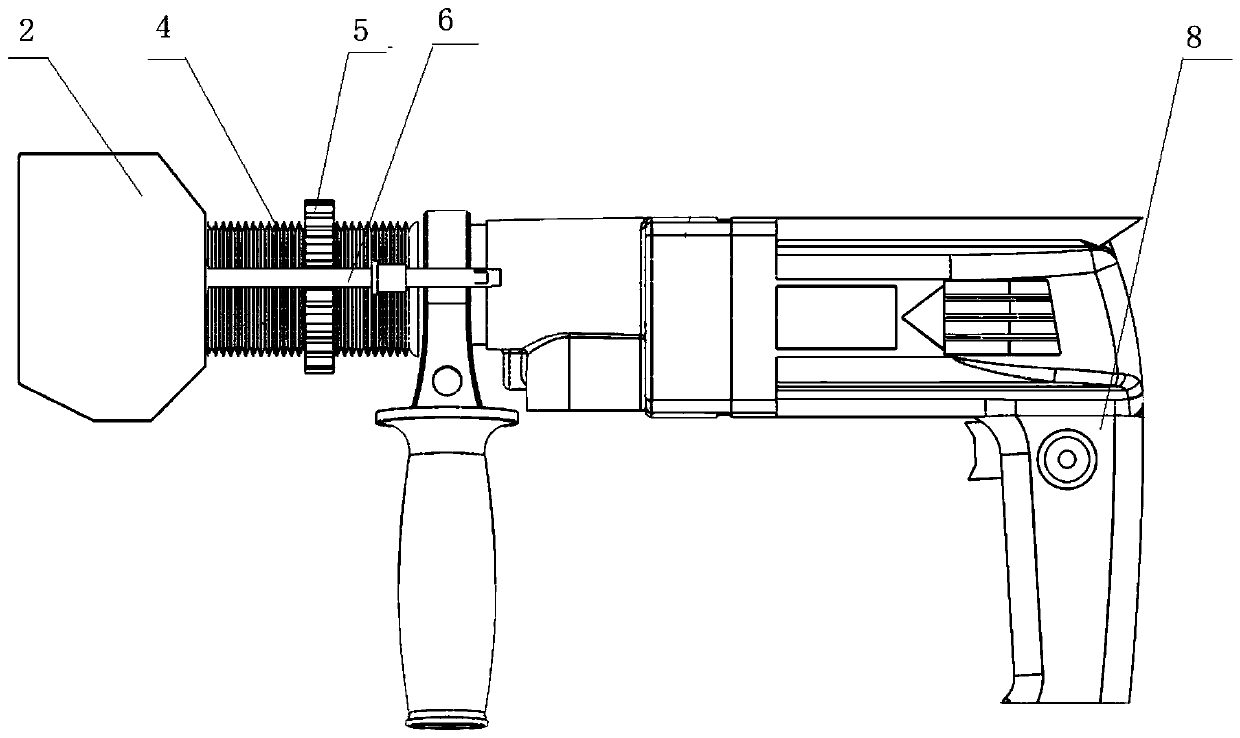

[0040] like Figure 1 to Figure 5 As shown, a portable concrete surface precision grinding powder sampling equipment, including sampling mechanism, precise adjustment mechanism and collection mechanism,

[0041] The sampling mechanism is provided with a grinding head and an electric drill body in sequence from front to back. The electric drill body includes a drill bit and a drill bit mounting seat. The grinding head and the drill bit are connected as an integrated structure. The drill bit is connected to the motor shaft through the drill bit mounting seat. , the grinding head is mounted on the free end of the drill bit;

[0042] The precise adjustment mechanism includes a threaded cylinder and a fixed ruler. The threaded cylinder is arranged on the outer side of the drill bit mounting seat. The inner wall of the fixed ruler is provided with an internal thread that matches the threaded cylinder. The threaded cylinder and the fixed ruler are both set as cylindrical cylinders S...

Embodiment 2

[0050] On the basis of Example 1, different from Example 1, such as Image 6 and Figure 7 As shown, the grinding head is set as a hollow diamond grinding head, and the hollow diamond grinding head is a detachable grinding head. The center of the grinding head is provided with a hollow hole I. More specifically: the center position of the grinding head passes through the dumbbell-shaped grinding head. Two symmetrical arc-shaped hollow holes I are formed at intervals between the stones. The center of the dumbbell-shaped grinding stone protrudes outwards and is provided with a tapered tip. There is a circle of hollow holes II on the outer edge of the inner ring grinding teeth. The center of the stone protrudes outwards and is provided with a conical tip. The hollow diamond grinding head is set as a structure formed by concentric arrangement of the inner ring grinding teeth and the outer ring grinding teeth. The radius of the outer ring grinding teeth is 20-30mm ; The hollow hol...

Embodiment 3

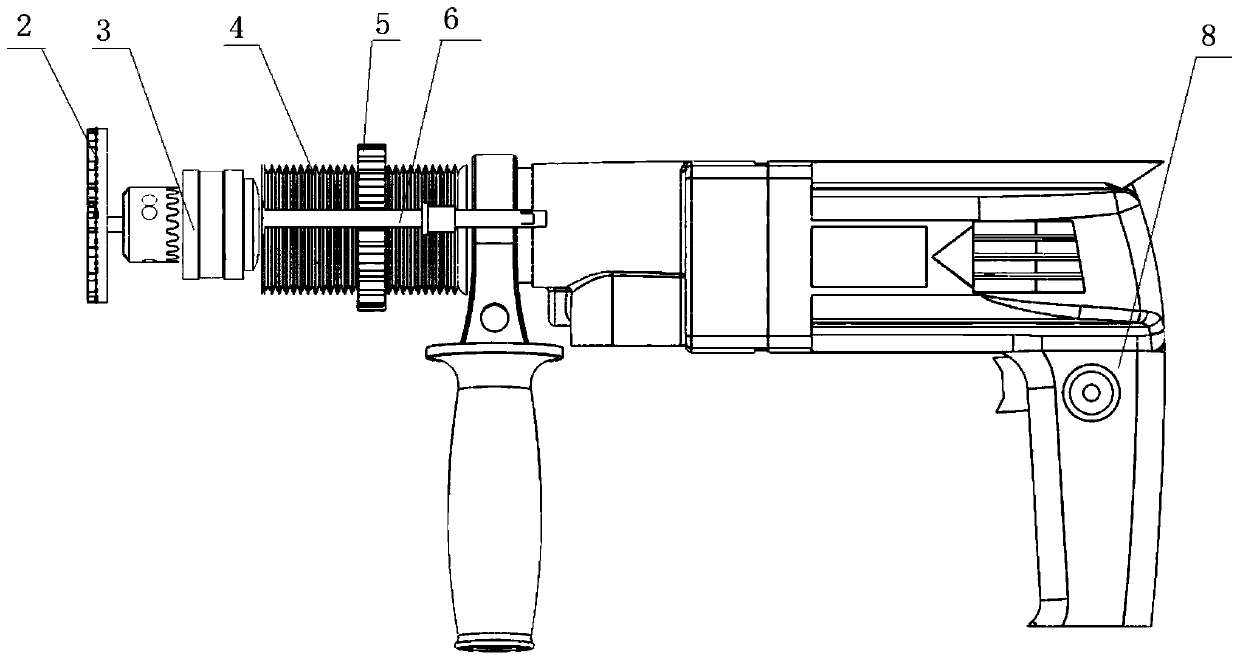

[0054] On the basis of Example 1, different from Example 1, such as Figure 4 As shown, the grinding head is set as a detachable structure, and the grinding head is removed from the end of the equipment for drilling.

[0055] A portable drilling device comprising a drilling mechanism, a precise adjustment mechanism and a collecting mechanism,

[0056] The drilling mechanism is provided with an electric drill body and a handle in sequence from front to back. The electric drill body includes a drill bit and a drill bit mounting seat. The drill bit is connected to the motor shaft through the drill bit mounting seat. .

[0057] The precise adjustment mechanism includes a threaded cylinder and a fixed ruler. The threaded cylinder is arranged on the outer side of the drill bit mounting seat. The inner wall of the fixed ruler is provided with an internal thread that matches the threaded cylinder. The threaded cylinder and the fixed ruler are both set as cylindrical cylinders Struct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com