High-dietary-fiber low-antigen protein fermented soybean hull and preparation method thereof

A technology with high dietary fiber and antigenic protein, applied in food processing, animal feed, animal feed, etc., can solve the problems of immature fermentation technology, unstable product quality, poor feed conversion rate, etc., and achieve the purpose of retaining nutrients and saving feed Grain formulation space, effect of reducing feed cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

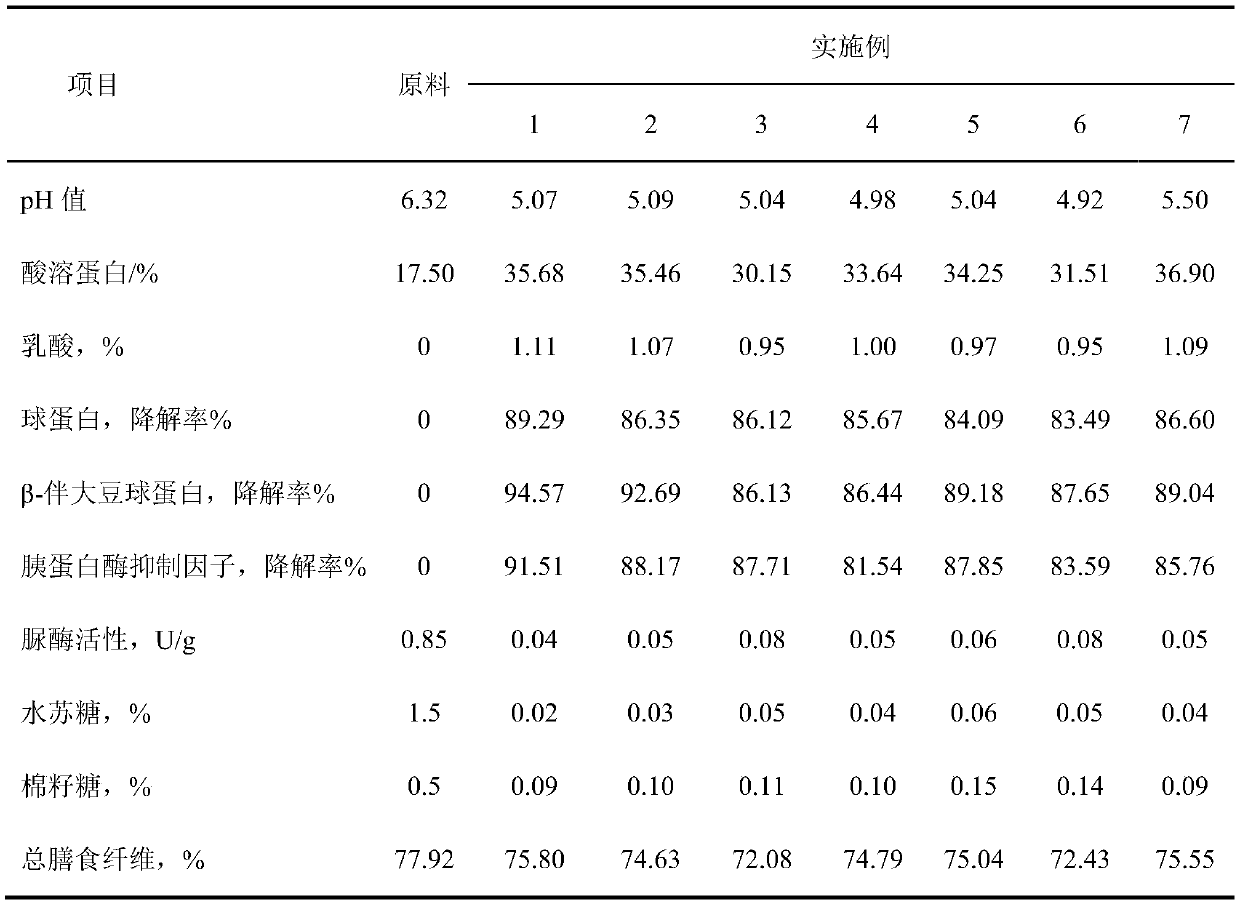

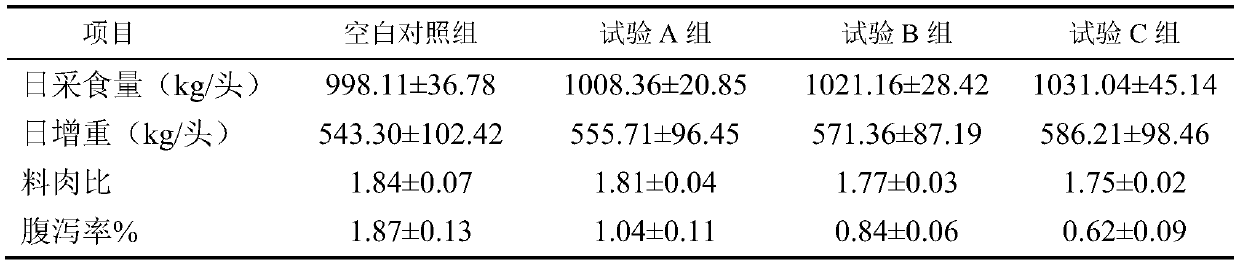

Examples

Embodiment 1

[0031] 1) Seed solution preparation, that is, the preserved Bacillus subtilis, Lactobacillus plantarum and Candida utilis strains were respectively inoculated into LB medium and MRS medium, and YPD medium was used to activate the seed solution of the strains. Further, the above-mentioned three kinds of seed liquids of Bacillus subtilis, Lactobacillus plantarum and Candida utilis were expanded and cultured for 21 hours to obtain fermentation liquid.

[0032] 2) Prepare the starter for the first stage of fermentation, that is, put the Bacillus subtilis, molasses, and urea in the starter components of the first stage according to the determined addition amount of each component of the starter of the first stage. ℃ warm water, stir evenly, and prepare an aerobic starter. The above-mentioned first three substances are respectively 5.18 parts, 0.78 parts and 0.21 parts by weight.

[0033] 3) Mix the aerobic starter and soybean hulls obtained in step 2, and mix evenly to obtain the ...

Embodiment 2

[0039] 1) Seed solution preparation, that is, the preserved Bacillus subtilis, Lactobacillus plantarum and Candida utilis strains were respectively inoculated into LB medium and MRS medium, and YPD medium was used to activate the seed solution of the strains. Further, the three seed liquids of Bacillus subtilis, Lactobacillus plantarum and Candida utilis were expanded and cultured for 23 hours to obtain fermentation liquid.

[0040] 2) Prepare the starter for the first stage of fermentation, that is, put the Bacillus subtilis, molasses, and urea in the starter components of the first stage according to the added amount of each component of the starter starter determined to be heated to 30 ℃ warm water, stir evenly, and prepare an aerobic starter. The above-mentioned first three substances are respectively 5.17 parts, 1.03 parts and 0.26 parts by weight.

[0041] 3) Mix the aerobic starter and soybean hulls obtained in step 2, and mix evenly to obtain the raw material of soybe...

Embodiment 3

[0047] 1) Seed solution preparation, that is, the preserved Bacillus subtilis, Lactobacillus plantarum and Candida utilis strains were respectively inoculated into LB medium and MRS medium, and YPD medium was used to activate the seed solution of the strains. Further, the three seed liquids of Bacillus subtilis, Lactobacillus plantarum and Candida utilis were expanded and cultured for 20 hours to obtain a fermentation liquid.

[0048] 2) Prepare the starter for the first stage of fermentation, that is, put the Bacillus subtilis, molasses, and urea in the starter components of the first stage according to the added amount of each component of the first stage starter that has been heated to 40 ℃ warm water, stir evenly, and prepare an aerobic starter. The above-mentioned first three substances are respectively 5.20 parts, 0.52 parts and 0.16 parts by weight.

[0049] 3) Mix the aerobic starter and soybean hulls obtained in step 2, and mix evenly to obtain the raw material of so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com