A kind of production method of methyl carbamate

A technology of methyl carbamate and its production method, which is applied in the production field of methyl carbamate, can solve problems such as potential safety hazards, blockage of reactor pipelines, etc., and achieve the effects of smooth production reaction, increased yield, and perfect industrial conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

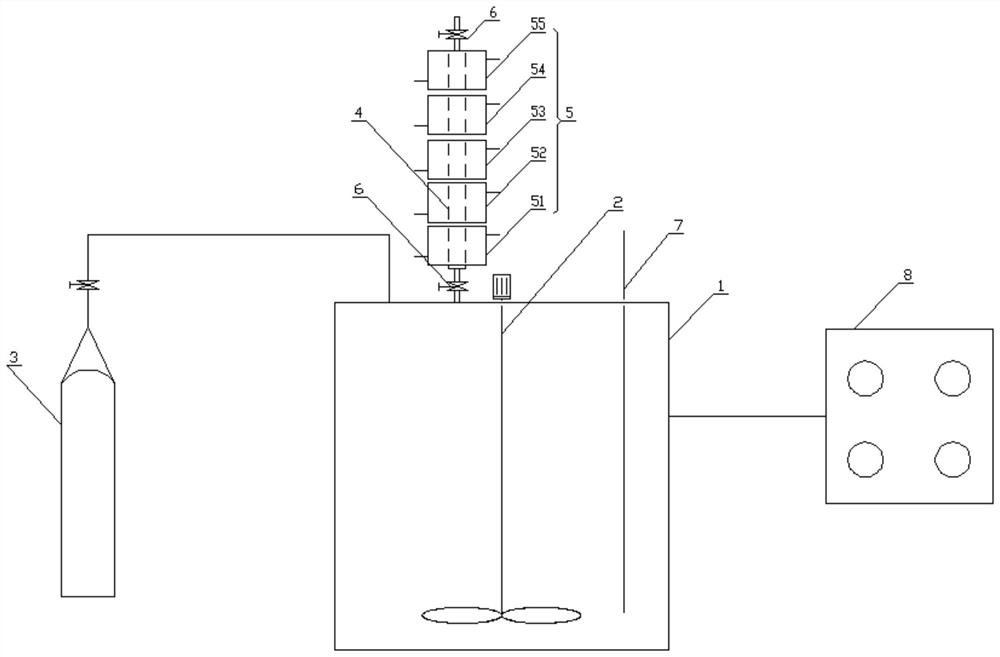

[0021] Equipment used in the production of methyl carbamate, such as figure 1 As shown, the equipment includes a reactor 1, the reactor 1 is provided with an agitator 2 and a temperature measuring thermocouple 7, the agitator 2 and the temperature measuring thermocouple 7 are connected to a controller 8, and the reactor 1 is connected to an inert gas storage cylinder 3 , the reactor 1 is provided with an exhaust channel 4 (exhaust pipe), the exhaust channel 4 is pressure-resistant 10Mpa, and the exhaust channel 4 is provided with five sections of independent outer pipes 5 ( figure 1 From bottom to top, there are outer tube 51, outer tube 52, outer tube 53, outer tube 54, outer tube 55), the outer tube 5 can be a metal tube, and an inlet and an outlet are respectively arranged on each section of the outer tube. The outlet and outlet can be used to connect the circulation pipeline, and the valves 6 for releasing gas are respectively arranged on the exhaust channels 4 located bel...

Embodiment 2

[0023] A production method of methyl carbamate, adopting the equipment in embodiment 1 to produce, wherein, the length of outer tube 51 is 0.2m, the length of outer tube 52 is 0.15m, the length of outer tube 53 is 0.1m, and the length of outer tube 54 is 0.05m, and the length of the outer pipe 55 is 0.01m.

[0024] The steps to produce methyl carbamate include:

[0025] Step 1: First introduce 6000mL of methanol, 426g of urea and 21g of catalyst into the reaction kettle in sequence, close the valve on the exhaust channel for releasing gas, and then flush 1.2MPa inert gas into the reaction system; the inert gas is nitrogen , the catalyst is titanium dioxide supported by silica, and the content of titanium dioxide is 2.9%;

[0026] Step 2: Control the temperature of the exhaust passage by dividing it into five sections. The pipe section of the exhaust passage where the outer pipe 51 is located uses tap water for temperature control, that is, tap water at 10°C is passed into the...

Embodiment 3

[0029] A production method of methyl carbamate, adopting the equipment in embodiment 1 to produce, wherein, the length of outer tube 51 is 0.3m, the length of outer tube 52 is 0.2m, the length of outer tube 53 is 0.15m, and the length of outer tube 54 is 0.1m, and the length of the outer pipe 55 is 0.05m.

[0030] The steps to produce methyl carbamate include:

[0031] Step 1: First introduce 6000mL of methanol, 426g of urea and 21g of catalyst into the reaction kettle in sequence, close the valve on the exhaust channel for releasing gas, and then flush 0.6MPa inert gas into the reaction system; the inert gas is nitrogen , the catalyst is titanium dioxide supported by silica, and the content of titanium dioxide is 2.9%;

[0032] Step 2: Control the temperature of the exhaust passage in 4 divided into five sections. The pipe section of the exhaust passage where the outer pipe 51 is located uses tap water for temperature control, that is, tap water at 4°C is passed into the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com