Preparation method of water-resistant phenolic resin adhesive

A phenolic resin glue and water resistance technology, used in adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc., can solve the problems of insufficient water resistance of phenolic resins, and improve water resistance and heat resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

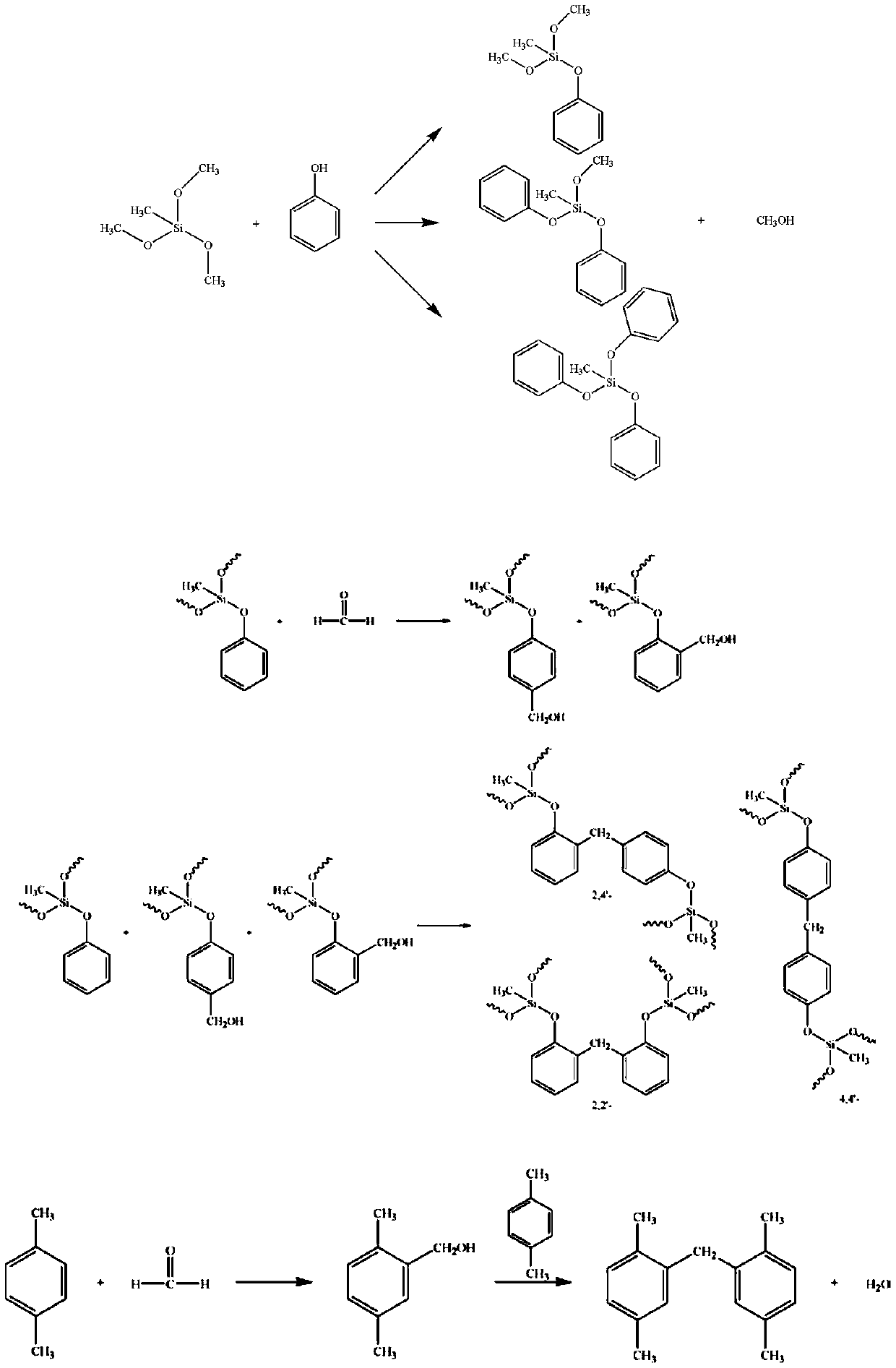

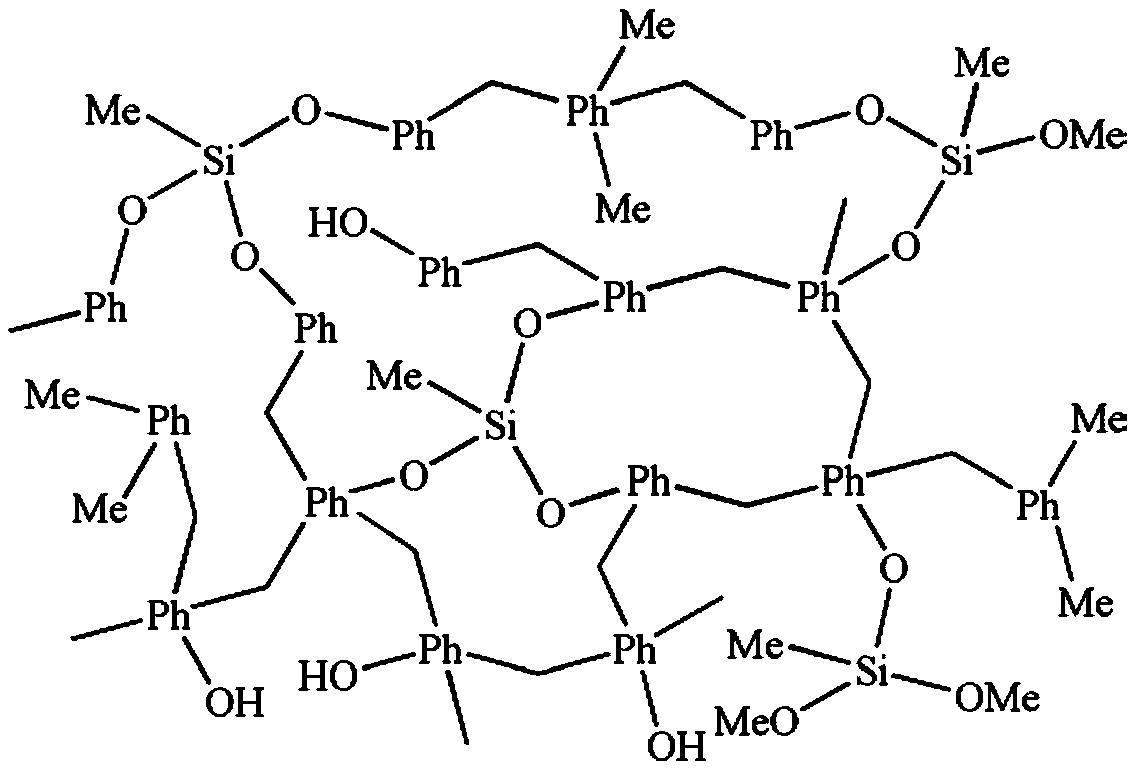

Method used

Image

Examples

Embodiment 1

[0022] 68.11g of methyltrimethoxysilane and 94.11g of phenol were mixed uniformly, 1.88g of methanesulfonic acid was added, the temperature was ramped up, and the reaction was carried out at 150 ° C to obtain an intermediate of alkylphenoxysilane; then cooled down, added 32.94g Xylene and 24.04 g of paraformaldehyde were reacted with an alkylphenoxysilane intermediate at 85° C. to the end point, distilled under reduced pressure, and dried under vacuum to obtain a water-resistant phenolic resin adhesive.

Embodiment 2

[0024] 41.27g of N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane and 94.11g of phenol were mixed uniformly, 1.41g of phosphoric acid was added, the temperature was gradually increased, and the reaction was carried out at 160 ° C to obtain alkane After cooling down, adding 23.53g of xylene and 26.13g of paraformaldehyde, reacted with the alkylphenoxysilane intermediate at 85 ° C to the end point, distilled under reduced pressure, and vacuum-dried to prepare Water-resistant phenolic resin adhesive.

Embodiment 3

[0026] 116.20 g of methyltrimethoxysilane and 228.29 g of bisphenol A were mixed uniformly, 3.44 g of p-toluenesulfonic acid was added, the temperature was gradually increased, and the reaction was carried out at 175 ° C to obtain an intermediate of alkylphenoxysilane; 68.49g of xylene and 70.61g of aqueous formaldehyde solution were added, reacted with the alkylphenoxysilane intermediate at 90° C. to the end point, distilled under reduced pressure, and dried under vacuum to obtain a water-resistant phenolic resin adhesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com