Denitration catalyst with core-shell structure and preparation method thereof

A denitration catalyst and core-shell structure technology are applied in the field of catalyst preparation, which can solve the problems of poor catalytic performance and poor water resistance in the low temperature region, achieve excellent catalytic activity and solve the effect of insufficient water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of Nucleus Phase Molecular Sieve Cu-Ce-La-SSZ-13

[0032] Dissolve 1.25g of sodium hydroxide in deionized water. After the dissolution is complete, add 2.082g of aluminum sulfate and keep stirring until the solution is reached. Then slowly drop 13.28g of silica sol (25wt%) into the above solution without stratification. In the case of a colloidal solution, slowly add a mixed solution of 6.2g N,N,N-trimethyl-1-adamantylammonium hydroxide (25wt%) and 10mL deionized water. After stirring mechanically at a constant temperature of 25°C for 12h, it was loaded into a hydrothermal reaction kettle, and reacted in a homogeneous phase at 160°C for 96h at a speed of 4r / min. After the crystallization, centrifuge and wash with water at a speed of 4800r / min, 5min each time, until the pH of the solution is 7. The centrifuged samples were dried at 80°C. The dried samples were ground and put into the calciner, the temperature was programmed to rise at 2°C / min, and the const...

Embodiment 2

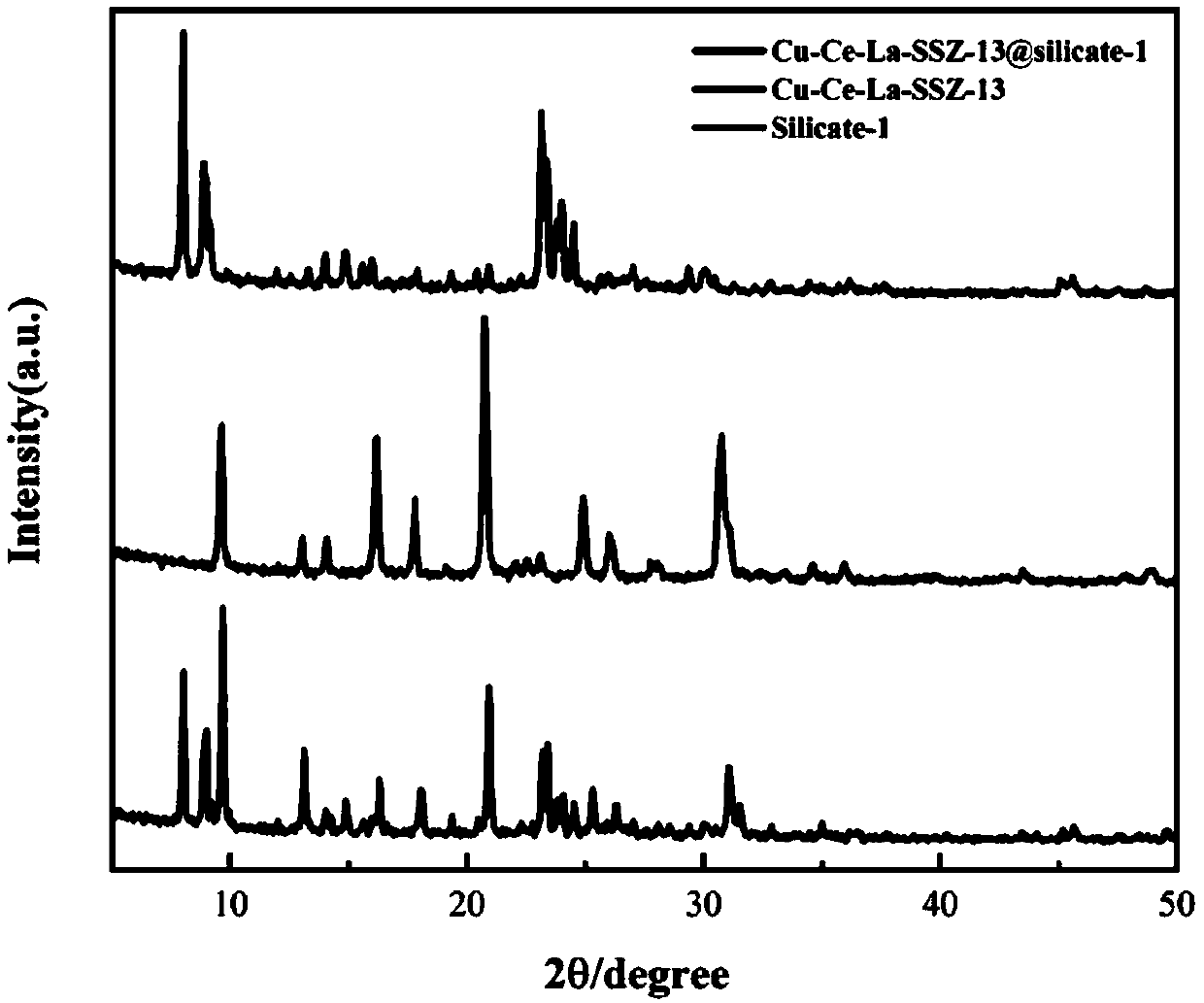

[0034] Cu-Ce-La-SSZ-13@silicate-1 with core-shell structure

[0035] Cu-Ce-La-SSZ-13 was synthesized according to the method in Example 1. Then put 1g of Cu-Ce-La-SSZ-13 sample into 100mL7g / L polydiallyldimethylammonium chloride solution, react in a water bath at 70°C for 20min, and centrifuge and wash once at a speed of 4800r / min. Dry in an oven at 60°C to obtain functionalized Cu-Ce-La-SSZ-13, which is designated as F-SSZ-13. Weigh 6g tetrapropylammonium hydroxide solution (25wt%), 9.65g tetraethyl orthosilicate, 45g deionized water (same according to claim 3), mix the three, and stir at room temperature for 5h. Add F-SSZ-13 into the seed crystal precursor solution and stir for 30 minutes, then centrifuge at 4800r / min and wash once with water. Cu-Ce-La-SSZ-13 with adsorbed seed crystals was obtained, which was denoted as FS-SSZ-13. Prepare core-shell silicate-1 precursor solution (1.21g tetrapropylammonium hydroxide solution, 5.1g ethyl orthosilicate, 80g deionized water,...

Embodiment 3

[0037] The denitrification activity of the catalyst was tested on a fixed bed reactor device. The catalyst used in the test was Cu-Ce-La-SSZ-13@silicate-1 with a mass of 50mg and a gas space velocity (GHSV) of 20000h -1 , the simulated flue gas inlet contains 500ppm NO, 500ppm NH 3 , 5%O 2 , the carrier gas is N 2 . The gas flow rate is regulated by a mass flow controller, and the total flow rate of the imported gas is 250mL min -1 . The mixed gas passes through the preheater before contacting the catalyst, and the temperature of the preheater is 150°C. Before the start of the experimental test, the simulated flue gas was passed into the reactor for about 1 hour to saturate the catalyst to adsorb NO and avoid the reduction of NO caused by the adsorption of the catalyst. The reaction temperature was controlled by temperature programming. After each change to the set temperature, the reaction system was stable for 30 minutes before starting the experiment. The concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com