Preparation method and application of multi-response platinum complex luminescent thin film

A platinum complex, luminescent thin film technology, applied in platinum group organic compounds, luminescent materials, chemical instruments and methods, etc., can solve the problems of easy loss of solutions and powder samples, unfavorable applications, etc., and achieve easy popularization and use and enhanced emission intensity. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

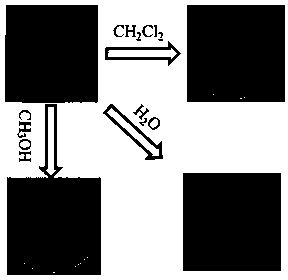

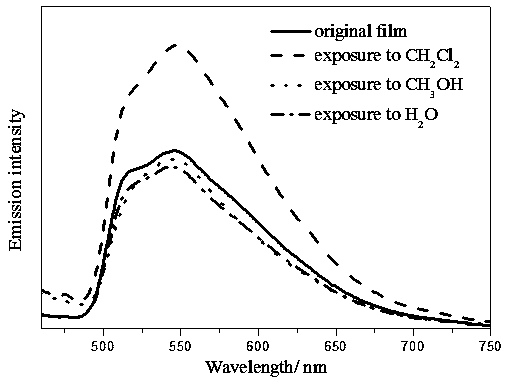

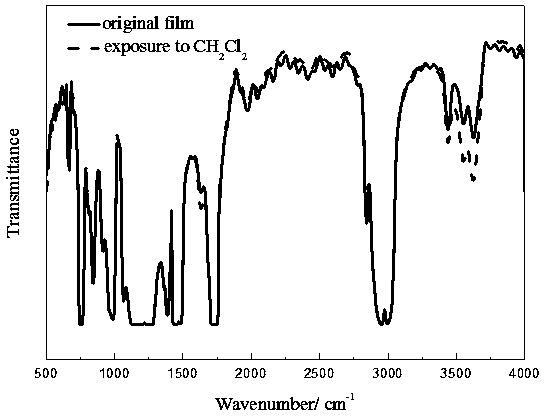

Image

Examples

Embodiment 1

[0039] A method for preparing a multiple-response platinum complex luminescent film, comprising the following steps:

[0040] (1) Prepare the platinum complex Pt(C^N^N)(Dmpi)Cl, react the platinum complex precursor with 2,6-dimethylbenzene isonitrile to prepare the pinene functionalized platinum complex, and then, The pinene functionalized platinum complex was recrystallized several times in chloroform solution to obtain the platinum complex Pt(C^N^N)(Dmpi)Cl;

[0041] (2) To prepare the platinum complex solution, at room temperature, completely dissolve 0.001g of the platinum complex Pt(C^N^N)(Dmpi)Cl in 10mL of chloroform to prepare a platinum complex solution with a concentration of 0.1 g / L ;

[0042](3) To prepare a polymethyl methacrylate solution, dissolve 0.5 g of polymethyl methacrylate in 10 mL of chloroform at room temperature, and ultrasonically stir until the polymethyl methacrylate is completely dissolved to obtain a concentration of 5 g / L polymethyl methacrylat...

Embodiment 2

[0048] A method for preparing a multiple-response platinum complex luminescent film, comprising the following steps:

[0049] (1) Prepare the platinum complex solution. Referring to Example 1, the platinum complex Pt(C^N^N)(Dmpi)Cl is prepared; at room temperature, 0.005g of the platinum complex Pt(C^N^N)(Dmpi )Cl was completely dissolved in 10mL of chloroform to obtain a platinum complex solution with a concentration of 0.5 g / L;

[0050] (2) Prepare polymethyl methacrylate solution. Dissolve 1 g of polymethyl methacrylate in 100 mL of chloroform at room temperature and ultrasonically stir until completely dissolved to obtain polymethacrylic acid with a concentration of 10 g / L. methyl ester solution;

[0051] (3) Prepare a compound solution. Stir and mix the above platinum complex solution and polymethyl methacrylate at room temperature to prepare a compound solution with a mass ratio of polymethyl methacrylate to platinum complex of 200:1 ;

[0052] (4) To prepare the plat...

Embodiment 3

[0054] A method for preparing a multiple-response platinum complex luminescent film, comprising the following steps:

[0055] (1) Prepare the platinum complex solution. Referring to Example 1, the platinum complex Pt(C^N^N)(Dmpi)Cl is prepared; at room temperature, 0.005g of the platinum complex Pt(C^N^N)(Dmpi )Cl was completely dissolved in 10mL of chloroform to obtain a platinum complex solution with a concentration of 0.5 g / L;

[0056] (2) Prepare polymethyl methacrylate solution. Dissolve 5 g of polymethyl methacrylate in 200 mL of chloroform at room temperature and ultrasonically stir until completely dissolved to obtain polymethacrylic acid with a concentration of 25 g / L methyl ester solution;

[0057] (3) Prepare the compound solution. Stir and mix the above platinum complex solution and polymethyl methacrylate solution at room temperature to prepare a compound with a mass ratio of polymethyl methacrylate to platinum complex of 1000:1. solution;

[0058] (4) To prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com