Industrial white oil production method

A production method and technology of industrial white oil, applied in the petroleum industry, hydrocarbon oil treatment products, hydrocarbon oil treatment, etc., can solve the problems of low kinematic viscosity, aromatics content, high requirements for kinematic viscosity flash point, low flash point, etc. Achieve high flash point, good hydrogenation effect and good interaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

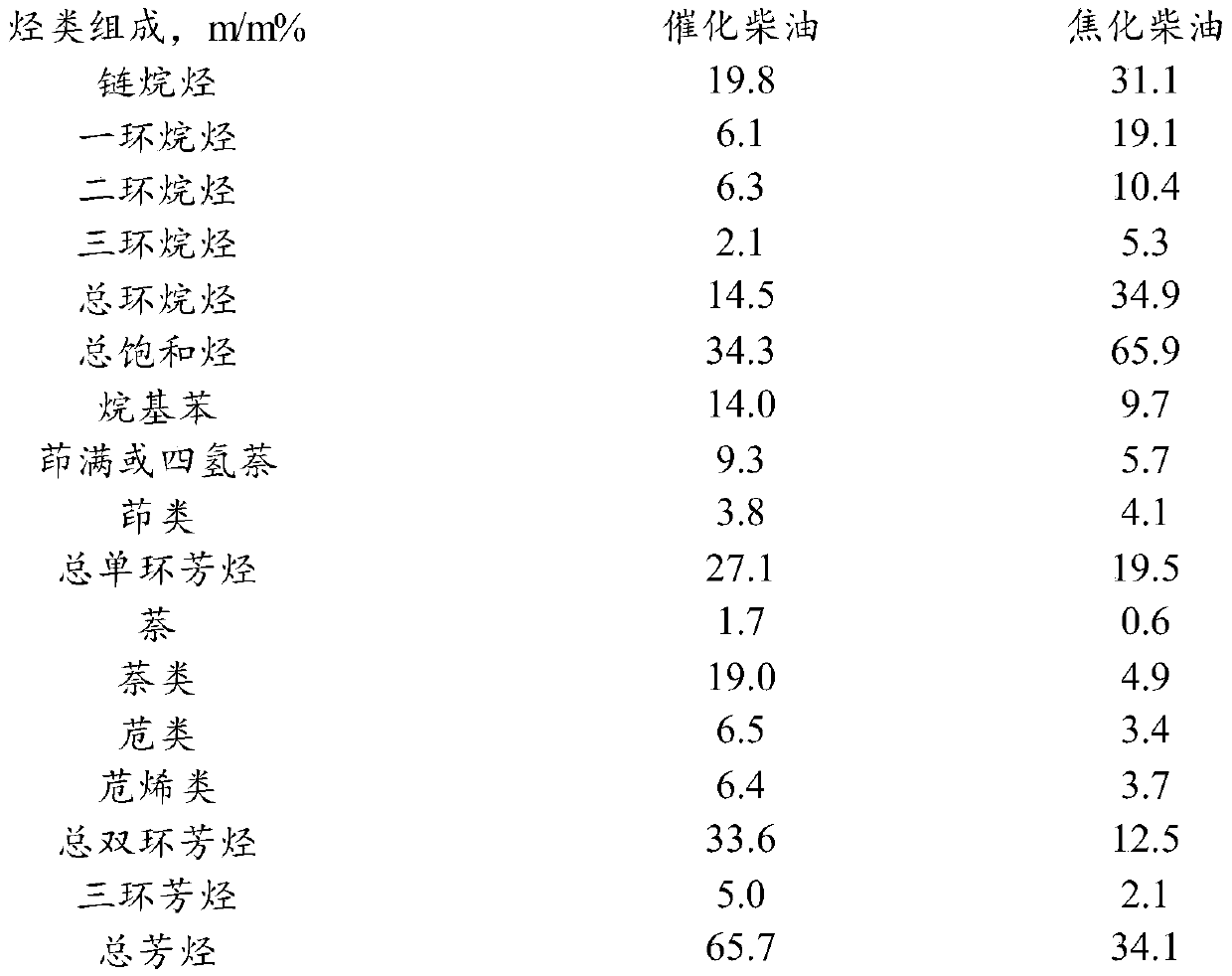

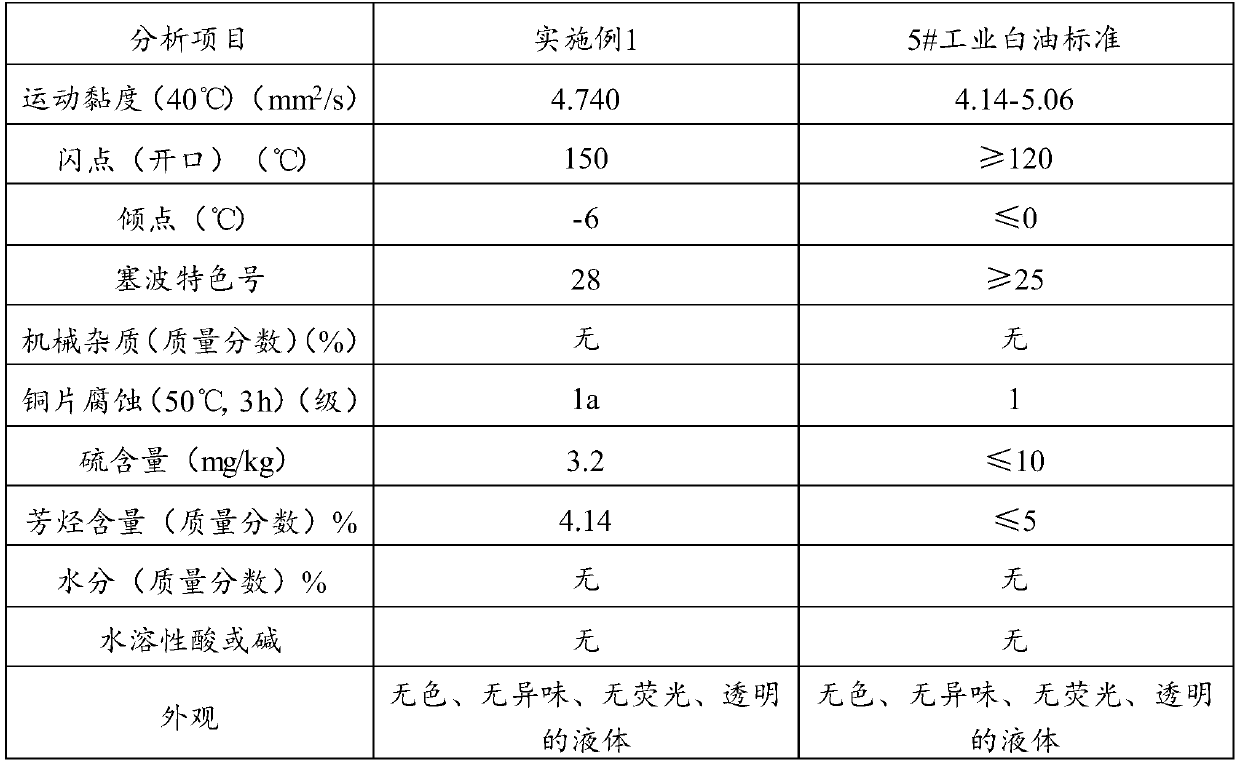

Embodiment 1

[0099] (1) Catalyzed diesel oil and coked diesel oil are filtered through the filter respectively, and then enter the raw material oil buffer tank, then boosted by the hydrogenation feed pump and mixed with hydrogen, and then enter the reaction feed heating furnace for heating after exchanging heat through the heat exchanger When the inlet temperature of the first reactor is 300°C, enter the first reactor for refining reaction, and control the temperature rise to 50°C-80°C; the pressure of the refining reaction is 10.5MPa-12.5MPa, and the liquid hourly volume space velocity is 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (500-900): 1; a refined reaction product is obtained.

[0100] (2) The refined reaction product obtained in step (1) directly enters the second reactor for cracking reaction, and the temperature rise is controlled at 50° C. to 80° C.; for 1h -1 ~3h -1 , the volume ratio of hydrogen to oil is (500-900): 1; the cracking reaction product is obtained. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap