Waterborne mold release capable of eliminating air bubbles on concrete surface and preparation method of waterborne mold release

A concrete surface and release agent technology, applied in the field of concrete, can solve the problems of many surface air bubbles and low cost, and achieve the effects of eliminating air bubbles, reducing costs, and increasing the stability of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

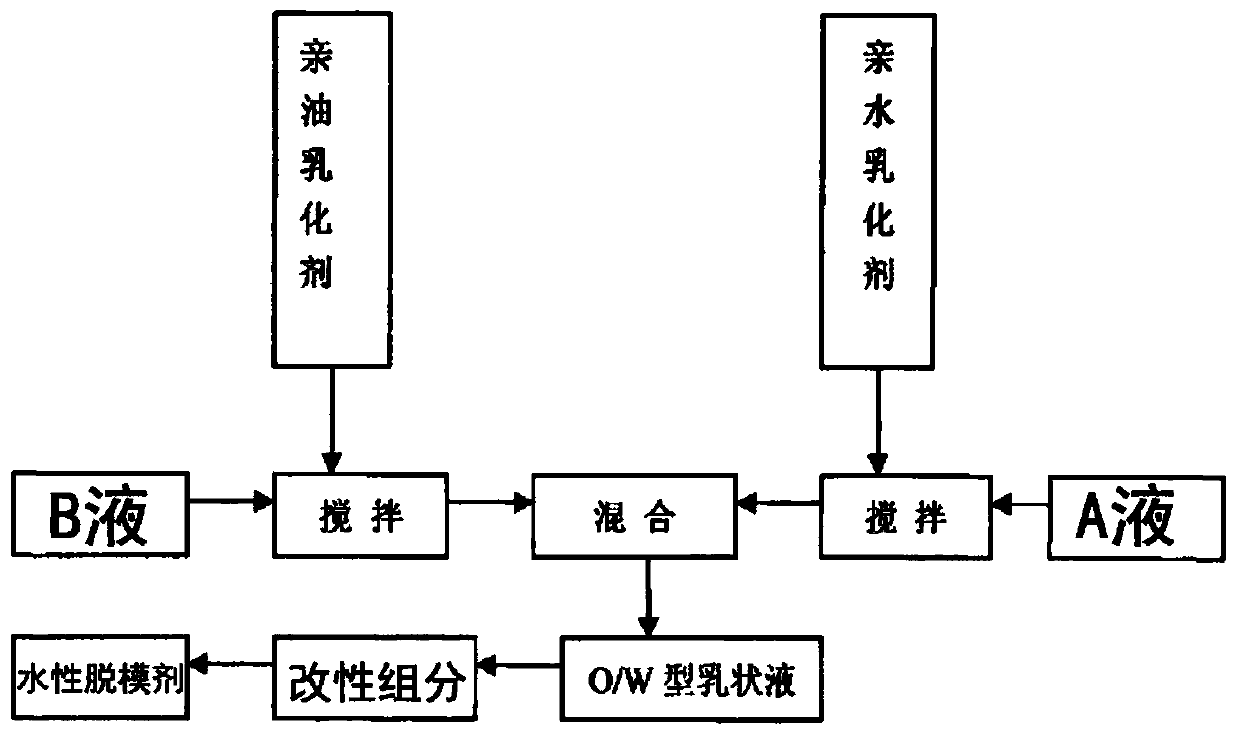

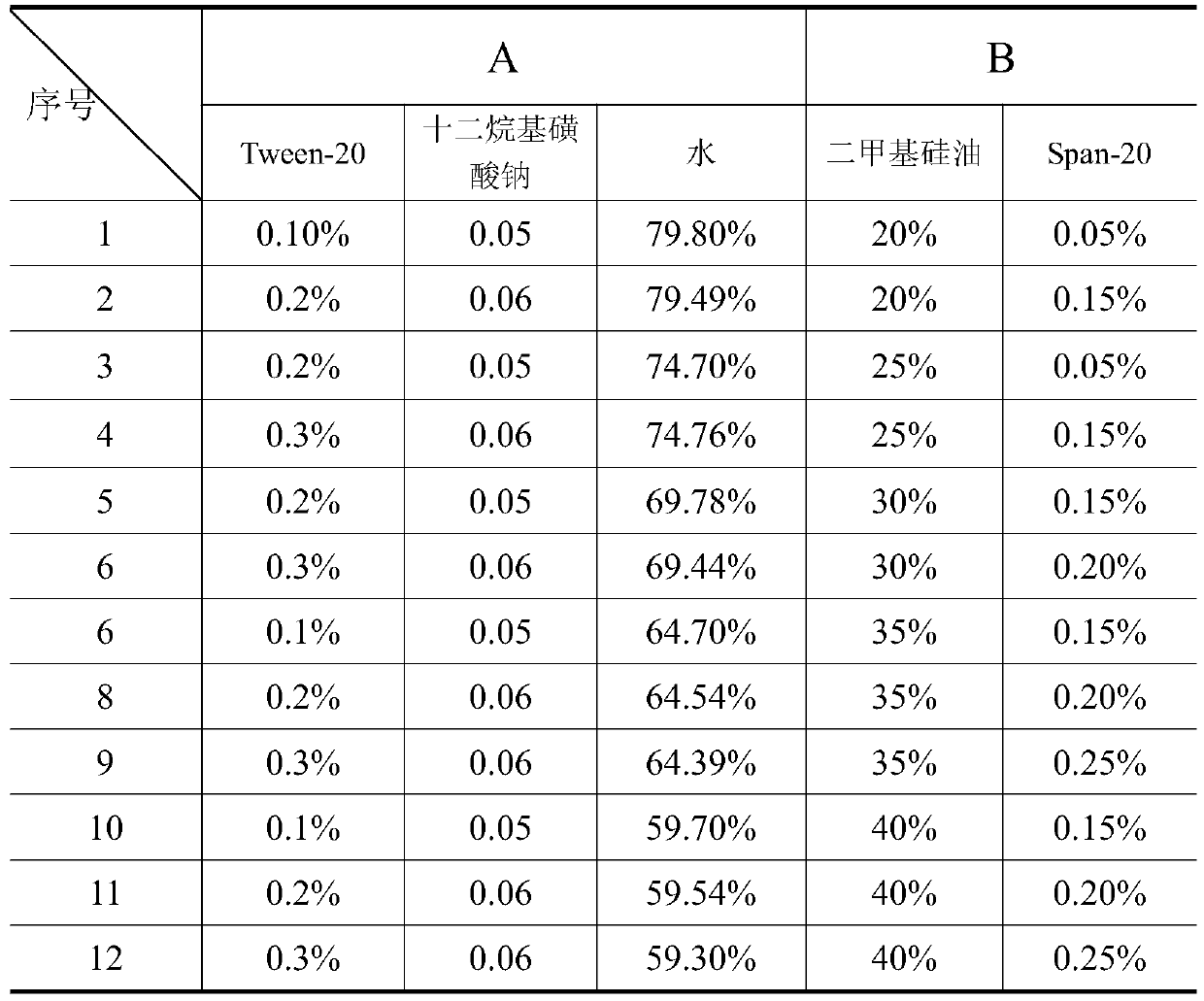

[0037] see figure 1 , the preparation method of the water-based release agent that can eliminate air bubbles on the concrete surface, in terms of mass percentage, includes the following components: 20-40% simethicone oil, 0.05-0.25% Span-20, 0.10-0.30 % of Tween-20, 0.05-0.07% of sodium dodecylsulfonate, 0.05-2.0% of compound modification components, and the balance is water; the compound modification components include tributyl phosphate and Ethylparaben;

[0038] 1) Prepare liquid A with Tween-20, sodium dodecylsulfonate, and water, and take it at any time;

[0039] 2) Stir simethicone and Span-20 evenly in an environment of 40-60°C until the mixture is milky white to make liquid B;

[0040] 3) Slowly add liquid A to liquid B, and stir while adding at a temperature of 40-60°C until liquid A is completely added, then add compound modified components in turn, stir and mix evenly to obtain a water-based release agent ;

[0041] The water-based mold release agent is directly...

Embodiment 1

[0053] A water-based mold release agent for solving excessive air bubbles on the surface of concrete, based on the total mass of the water-based mold release agent, the raw material components of the water-based mold release agent include 20% to 40% of simethicone, 0.05% ~0.25% Span-20, 0.10%~0.30% Tween-20, 0.05%~0.07% Sodium Lauryl Sulfate, and 0.03% Tributyl Phosphate and 0.02% Ethylparaben.

[0054] Its preparation method is:

[0055] 1) Prepare liquid A with Tween-20, sodium dodecylsulfonate, and water, and take it at any time;

[0056] 2) Stir simethicone and Span-20 evenly in an environment of 40-60°C until the mixture is milky white to make liquid B;

[0057] 3) Slowly add liquid A to liquid B, and stir while adding at a temperature of 40-60°C until liquid A is completely added, then add compound modified components (tributyl phosphate, paraben B) in sequence ester), stirred and mixed evenly to obtain a water-based release agent.

[0058] The various components in t...

Embodiment 2

[0067] The difference between Example 2 and Example 1 lies in the compounded modified components, specifically the compounded modified components also include pH regulators, thickeners and metal ion shielding agents; the mass percentage of each component is: 0.01 ~0.8% tributyl phosphate, 0.01~0.5% ethylparaben, 0.01~0.2% pH regulator, 0.01~0.4% thickener and 0.01~0.3% metal ion shielding agent; thickening The agent can improve the wall-hanging property of the water-based release agent and increase the stability of the product, so that the release agent will not be lost during the vibration process.

[0068] Wherein, the pH regulator is a sodium hydroxide solution with a mass concentration of 2-10%, the thickener is a carboxymethyl cellulose solution with a mass concentration of 2-5%, and the metal ion shielding agent is EDTA.

[0069] By compounding the modified components and replacing the compounded modified components in Example 1, a water-based release agent with mold rel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com