A Reinforcement Construction Technology of Soft Soil Subgrade

A construction technology and technology of soft soil subgrade, which is applied in the directions of roads, roads, buildings, etc., can solve the problems of affecting the load stability of the road section reinforced by soft foundation, inconsistent vertical height of the bottom end of the immersed tube, etc., and achieve excellent structural strength and hardness, The effect of improving the ability to hang on the wall and improving the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

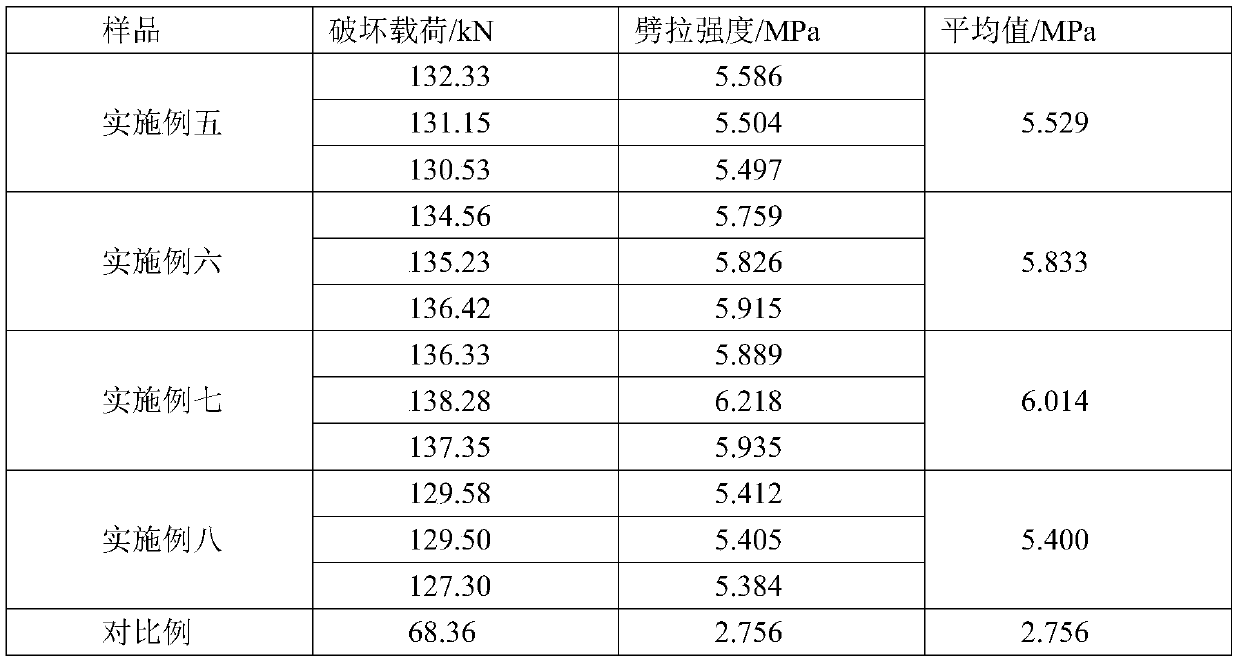

Examples

Embodiment 1

[0049] A kind of preparation process of acrylate-SEBS copolymer is as follows:

[0050] (1) Ingredients: Weigh 20 parts of methyl acrylate, 5 parts of isooctyl acrylate, 10 parts of SEBS thermoplastic elastomer, 10 parts of reinforcing filler inclusions, 5 parts of acrylic emulsion film former, N, N methylenebispropylene 1 part of amide, 0.5 part of dicumyl peroxide and 3 parts of acrylic dispersant;

[0051] (2) Preparation of reinforcing filler inclusions: use polyborosiloxane melt to wrap nano-calcium carbonate, the weight ratio of nano-calcium carbonate to polyborosiloxane is 2:1, and carry out low temperature at -40°C after wrapping Freeze for 24 hours, sinter at 300°C for 30 minutes after freezing, and pulverize the sintered body after cooling to room temperature;

[0052] (3) Preparation of acrylic emulsion film former: (1) Pre-emulsification: add 100 parts of water, 3 parts of emulsifier, 5 parts of acrylamide to the reaction bottle, add 5 parts of styrene and 10 part...

Embodiment 2

[0058] A kind of preparation process of acrylate-SEBS copolymer is as follows:

[0059] (1) Ingredients: Weigh 22 parts of methyl acrylate, 7 parts of isooctyl acrylate, 10 parts of SEBS thermoplastic elastomer, 14 parts of reinforcing filler inclusions, 5 parts of acrylic emulsion film former, N, N methylenebispropylene 1 part of amide, 0.7 part of dicumyl peroxide and 3 parts of acrylic dispersant;

[0060] (2) Preparation of reinforcing filler inclusions: use polyborosiloxane melt to wrap nano-calcium carbonate, the weight ratio of nano-calcium carbonate to polyborosiloxane is 2:1, and carry out low temperature at -40°C after wrapping Freeze for 24 hours, sinter at 300°C for 30 minutes after freezing, and pulverize the sintered body after cooling to room temperature;

[0061] (3) Preparation of acrylic emulsion film former: (1) Pre-emulsification: add 100 parts of water, 3 parts of emulsifier, 5 parts of acrylamide to the reaction bottle, add 5 parts of styrene and 10 part...

Embodiment 3

[0067] A kind of preparation process of acrylate-SEBS copolymer is as follows:

[0068] (1) Ingredients: Weigh 23 parts of methyl acrylate, 8 parts of isooctyl acrylate, 12 parts of SEBS thermoplastic elastomer, 18 parts of reinforcing filler inclusions, 8 parts of acrylic emulsion film former, N, N methylenebispropylene 2 parts of amide, 0.8 parts of dicumyl peroxide and 3 parts of acrylic dispersant;

[0069] (2) Preparation of reinforcing filler inclusions: use polyborosiloxane melt to wrap nano-calcium carbonate, the weight ratio of nano-calcium carbonate to polyborosiloxane is 2:1, and carry out low temperature at -40°C after wrapping Freeze for 24 hours, sinter at 300°C for 30 minutes after freezing, and pulverize the sintered body after cooling to room temperature;

[0070] (3) Preparation of acrylic emulsion film former: (1) Pre-emulsification: add 100 parts of water, 3 parts of emulsifier, 5 parts of acrylamide to the reaction bottle, add 5 parts of styrene and 10 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com