Production process of Gannan navel orange fermented distilled liquor

A production process and technology for distilled wine, applied in the field of production process of Gannan navel orange fermented distilled wine, can solve the problems of inability to form and use, loss of nutrients, environmental impact, etc., to improve the conversion rate of alcohol, increase nutritional value, and reduce loss. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

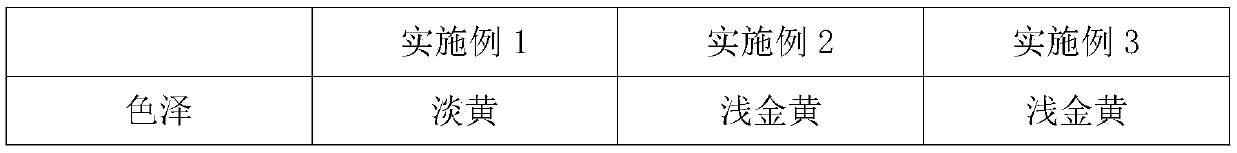

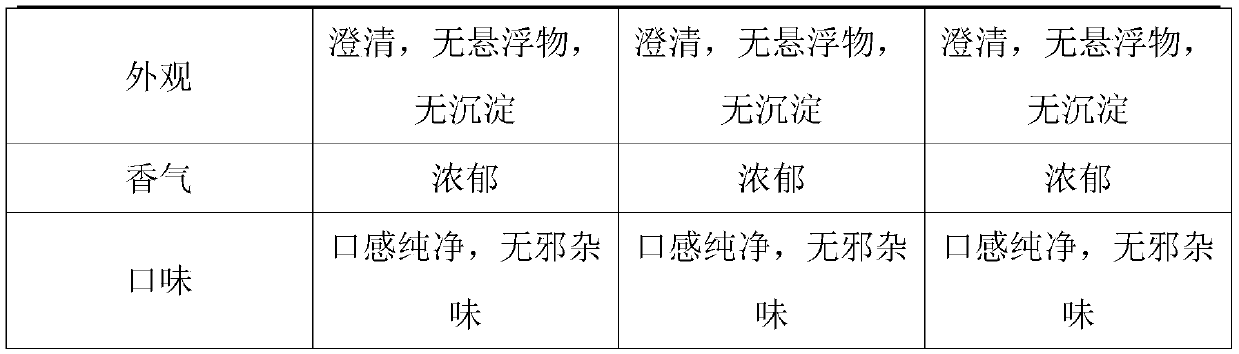

Embodiment 1

[0033] The production technology of Gannan navel orange fermented distilled wine comprises the following steps:

[0034] Step 1, the navel orange is cleaned and selected, and impurities are removed, and then the pulp of the navel orange is separated to obtain orange pulp and orange peel;

[0035] Step 2, putting the orange meat into a cooking machine for crushing to obtain crushed orange meat, then evenly mixing fruit wine yeast into the crushed orange meat to obtain mixed orange meat, and putting it into a fermenter;

[0036] Step 3, cut the orange peel into shreds, spread it on the surface of the minced orange meat in the fermenter, then seal the fermenter, and react with microwaves at intervals of 36 hours to obtain the primary fermented product;

[0037] Step 4, taking out the shredded orange peel on the surface and crushing it into crushed orange peel; filtering and separating the first-grade fermented product to obtain the first-grade wine liquid and the first-grade wine...

Embodiment 2

[0049] The production technology of Gannan navel orange fermented distilled wine comprises the following steps:

[0050] Step 1, the navel orange is cleaned and selected, and impurities are removed, and then the pulp of the navel orange is separated to obtain orange pulp and orange peel;

[0051] Step 2, putting the orange meat into a cooking machine for crushing to obtain crushed orange meat, then evenly mixing fruit wine yeast into the crushed orange meat to obtain mixed orange meat, and putting it into a fermenter;

[0052]Step 3, cut the orange peel into shreds, spread it on the surface of the minced orange meat in the fermenter, then seal the fermenter, and react with microwaves at intervals of 72 hours to obtain the primary fermented product;

[0053] Step 4, taking out the shredded orange peel on the surface and crushing it into crushed orange peel; filtering and separating the first-grade fermented product to obtain the first-grade wine liquid and the first-grade wine ...

Embodiment 3

[0065] The production technology of Gannan navel orange fermented distilled wine comprises the following steps:

[0066] Step 1, the navel orange is cleaned and selected, and impurities are removed, and then the pulp of the navel orange is separated to obtain orange pulp and orange peel;

[0067] Step 2, putting the orange meat into a cooking machine for crushing to obtain crushed orange meat, then evenly mixing fruit wine yeast into the crushed orange meat to obtain mixed orange meat, and putting it into a fermenter;

[0068] Step 3, cut the orange peel into shreds, spread it on the surface of the minced orange meat in the fermenter, then seal the fermenter, and react with microwaves at intervals of 48 hours to obtain the primary fermented product;

[0069] Step 4, taking out the shredded orange peel on the surface and crushing it into crushed orange peel; filtering and separating the first-grade fermented product to obtain the first-grade wine liquid and the first-grade wine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com