A hot-rolled medium-manganese steel with high-strength plastic product and no plastic instability and its preparation method

An unstable, high-strength plastic product technology, applied in high-strength plastic product and no plastic instability hot-rolled medium manganese steel plate and its preparation, in the field of automotive steel, can solve the problem of reducing the surface quality of formed parts and the impact of sheet metal processing and forming performance, etc. problems, to achieve the effect of good formability, high strength, and strong impact energy absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

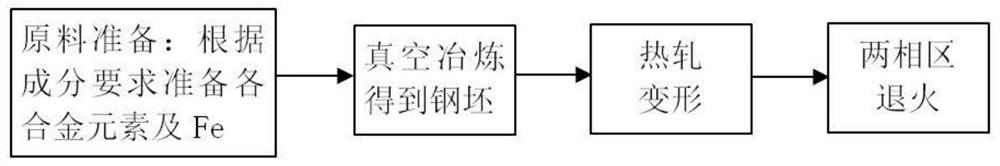

Method used

Image

Examples

Embodiment 1

[0024] The measured chemical composition of the manganese steel in Example 1 is shown in Table 1. The manganese steel with the above composition was smelted in a vacuum induction furnace for 40 minutes, cooled to room temperature to obtain a steel ingot, and a steel billet with a thickness of 70 mm was cut.

[0025] Manganese steel measured chemical composition (wt%) in the embodiment of table 1

[0026] C Si mn P S Al Fe 0.30 0.028 9.28 0.0075 0.0088 2.15 margin

[0027] Hot rolling was performed on a laboratory 4-high reversing mill. Heat the steel billet to 1180°C-1200°C for 2 hours, and then conduct multi-pass hot rolling. The starting temperature is 1100°C-1150°C. After 6 passes, it is rolled into a steel plate with a thickness of 3mm. The final rolling temperature is not lower than 900°C. Laminar cooling after rolling, the coiling temperature is 300℃~400℃.

[0028] The hot-rolled plate is annealed in the two-phase zone, the annealing t...

Embodiment 2

[0031] The chemical composition, smelting, and hot-rolling process of the steel are the same as in Example 1, except that the hot-rolled plate is annealed in the two-phase zone. The annealing process in the two-phase zone is at 630° C., the holding time is 30 minutes, and air-cooled to room temperature.

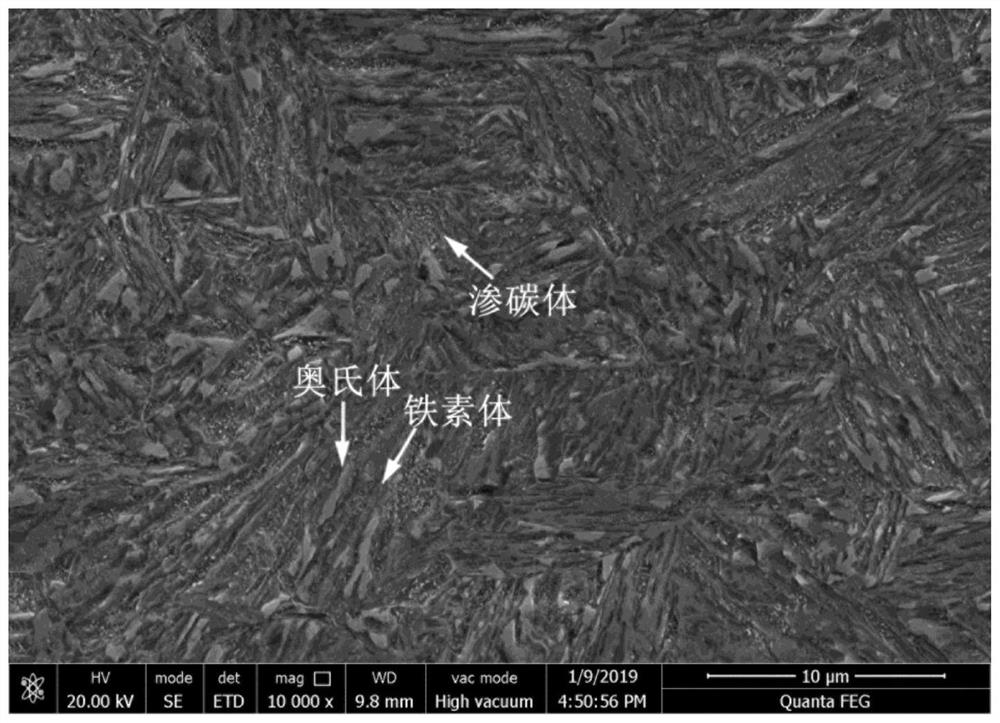

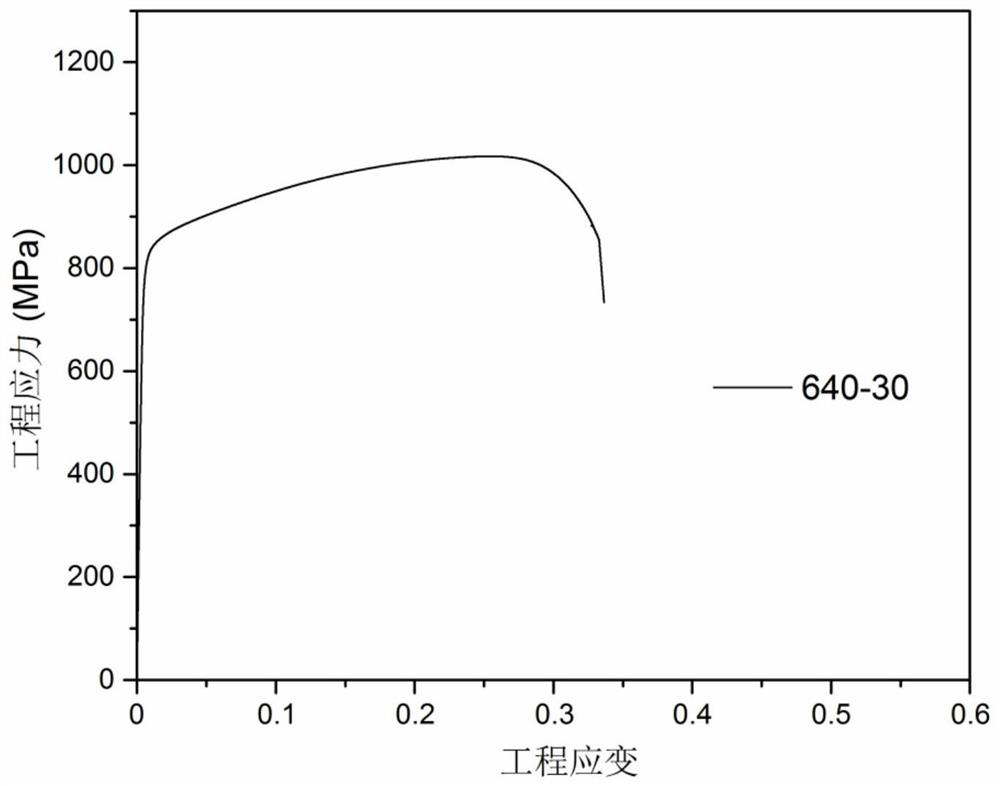

[0032] The microstructure observation ( Figure 4 ) and mechanical performance tests. Process the steel plate annealed in the two-phase region into a tensile sample with a gauge length of 50 mm, and conduct a uniaxial tensile test with the tensile rate set at 10 -3 the s -1 . Tensile result engineering stress-strain curve such as Figure 5 shown. It can be seen that after annealing in the two-phase region of the hot-rolled medium-manganese steel, its tensile strength is about 1000MPa, the strength-plastic product is greater than 30GPa·%, and the stress-strain curve shows continuous yield without stress vibration and other plastic instability. Phenomenon. This is closely...

Embodiment 3

[0034] The chemical composition, smelting, and hot-rolling process of the steel are the same as in Example 1, except that the hot-rolled plate is annealed in the two-phase zone. The annealing process in the two-phase zone is at 680° C., the holding time is 30 minutes, and air-cooled to room temperature.

[0035] The microstructure observation ( Image 6 ) and mechanical performance tests. Process the steel plate annealed in the two-phase region into a tensile sample with a gauge length of 50 mm, and conduct a uniaxial tensile test with the tensile rate set at 10 -3 the s -1 . Tensile result engineering stress-strain curve such as Figure 7 shown. It can be seen that the strength and elongation of the hot-rolled medium-manganese steel are higher after annealing in the two-phase region at 680°C for 30 minutes, but there is a phenomenon of stress jitter, which affects the formability of the sheet, and its microstructure is austenite and iron The two-phase structure of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com