Hydrogel flexible strain sensor with low Young modulus

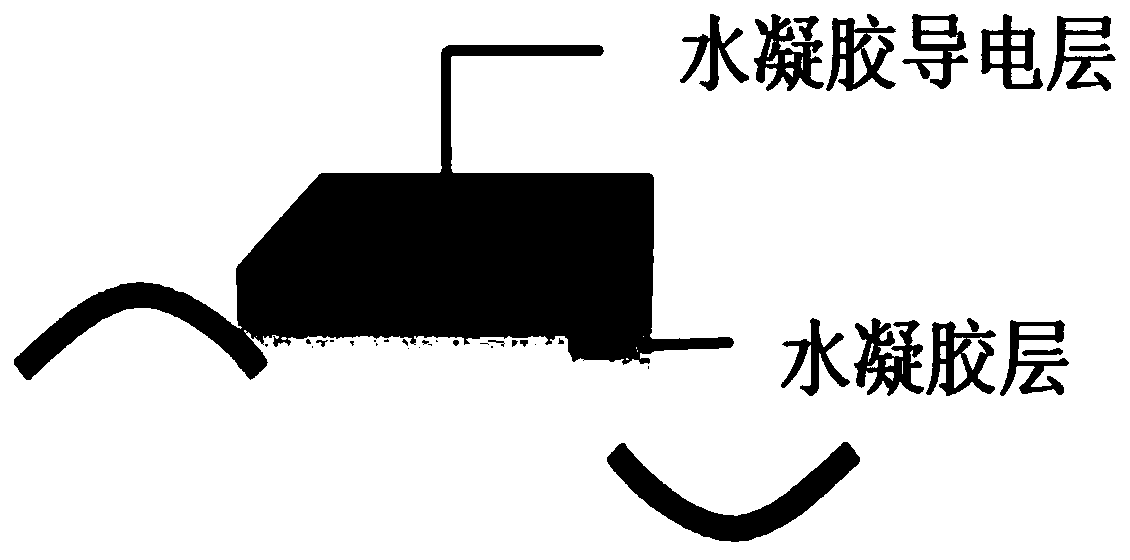

A strain sensor, hydrogel flexible technology, applied in the direction of electromagnetic measurement device, electric/magnetic solid deformation measurement, etc., to achieve the effect of good strain-resistance sensitivity, high stretchability, excellent cutting resistance and compression deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

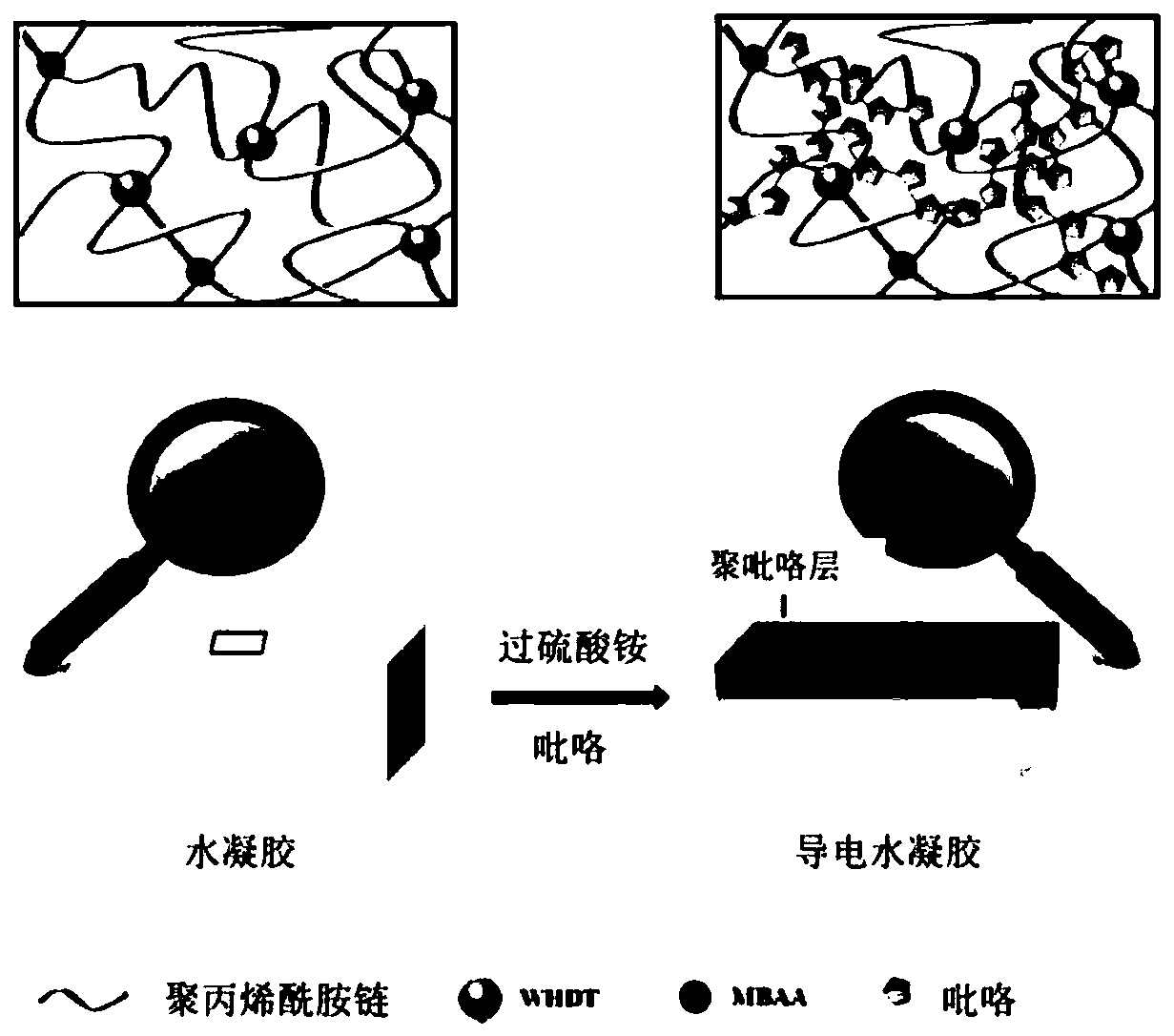

Method used

Image

Examples

Embodiment 1

[0041] Prepare the following reagents in advance:

[0042] 1. Waterborne hexamethylene diisocyanate trimer (WHDT):

[0043] Feed 7g of ethylene glycol monomethyl ether (molecular weight 700) and hexamethylene diisocyanate trimer 5g (molecular weight 500), and mix and stir for 12 hours at 75°C to obtain water-based hexamethylene diisocyanate trimer (WHDT) .

[0044] 2. Ammonium persulfate solution:

[0045]0.04g initiator ammonium persulfate (APS) was dissolved in 50g water to obtain ammonium persulfate solution.

[0046] Preparation method of the strain sensor:

[0047] (1) Dissolve 7.1g of acrylamide monomer (AAm) and 0.02g of chemical cross-linking agent N,N-methylenebisacrylamide (MBAA) in ammonium persulfate (APS) solution, and ultrasonicate for 3 minutes to obtain Hydrogel mother liquor (preparation and use now);

[0048] (2) At room temperature, mix 5mL of the hydrogel mother liquor and 0.15g of the prepared chemical cross-linking agent WHDT, stir until the solution...

Embodiment 2

[0051] Prepare the following reagents in advance:

[0052] 1. Waterborne hexamethylene diisocyanate trimer (WHDT):

[0053] Feed 7g of ethylene glycol monomethyl ether (molecular weight 700) and hexamethylene diisocyanate trimer 5g (molecular weight 500), and mix and stir for 12 hours at 75°C to obtain water-based hexamethylene diisocyanate trimer (WHDT) .

[0054] 2. Ammonium persulfate solution:

[0055] 0.04g initiator ammonium persulfate (APS) was dissolved in water to obtain ammonium persulfate solution.

[0056] Preparation method of the strain sensor:

[0057] (1) Dissolve 7.1 g of acrylamide monomer (AAm) and 0.02 g of chemical cross-linking agent N, N-methylenebisacrylamide (MBAA) in ammonium persulfate solution, and ultrasonicate for 3 minutes to obtain a hydrogel Mother liquor (prepared and used now);

[0058] (2) At room temperature, mix 5mL of the hydrogel mother liquor and 0.24g of the chemical cross-linking agent WHDT, stir until the solution is clear; pour...

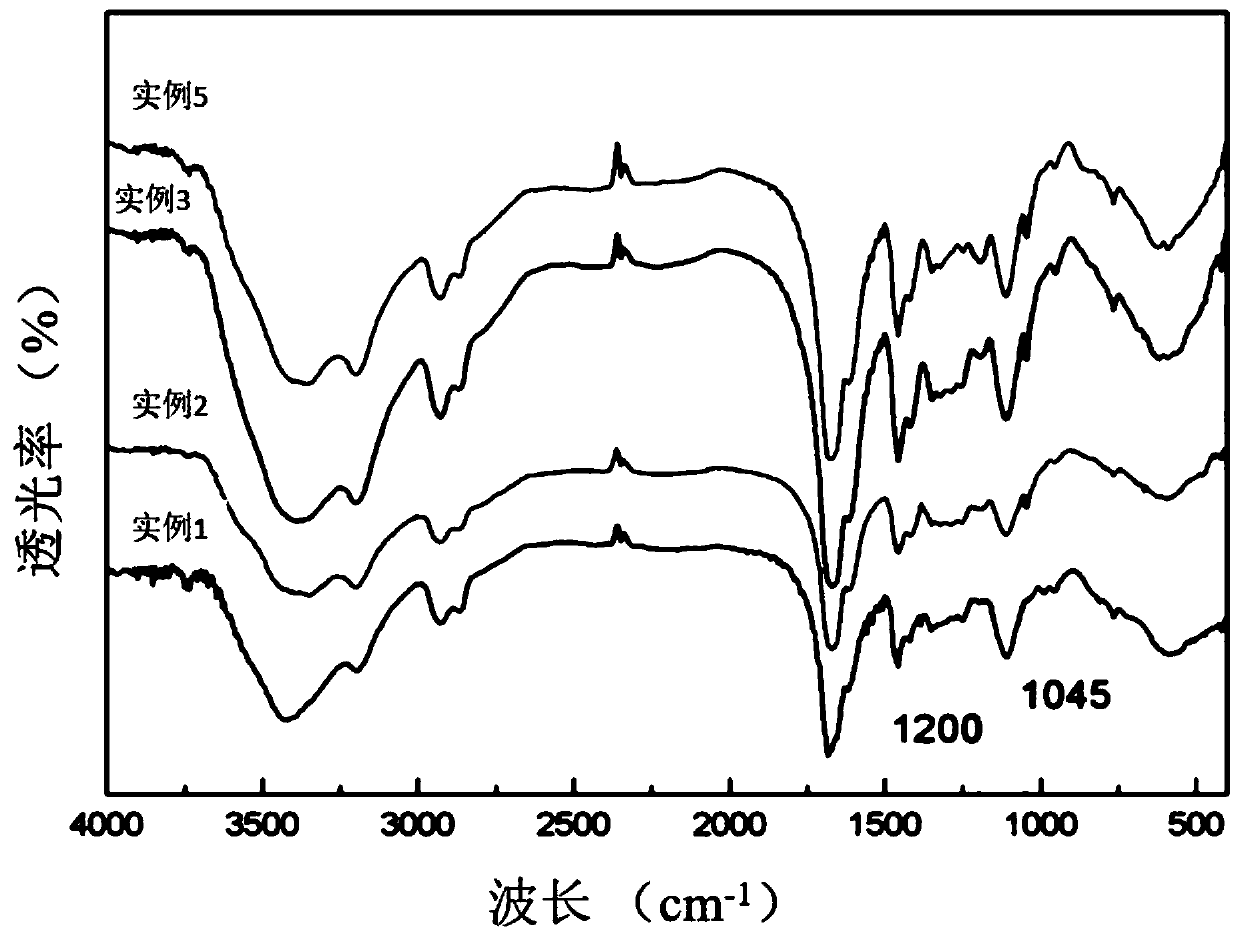

Embodiment 3~8

[0061] In Examples 3-8, the time for soaking the hydrogel in pyrrole and the initiator APS is shown in Table 1. All the other steps are as in Example 1.

[0062] Table 1 The soaking time of conductive hydrogel in pyrrole and APS

[0063]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com