Preparation method of graphite negative electrode material

A technology of graphite negative electrode and negative electrode material, applied in the directions of graphite, chemical instruments and methods, battery electrodes, etc., can solve the problems of poor purification effect of graphite material, poor beneficiation effect of graphite ore, poor cycle stability, etc. Small diameter, high carbon purity, and the effect of lowering the reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

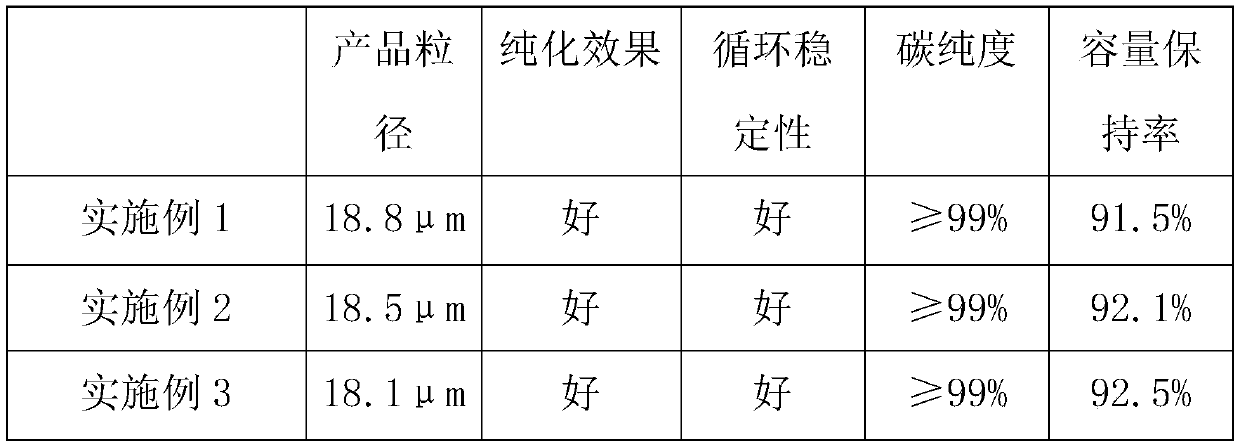

Embodiment 1

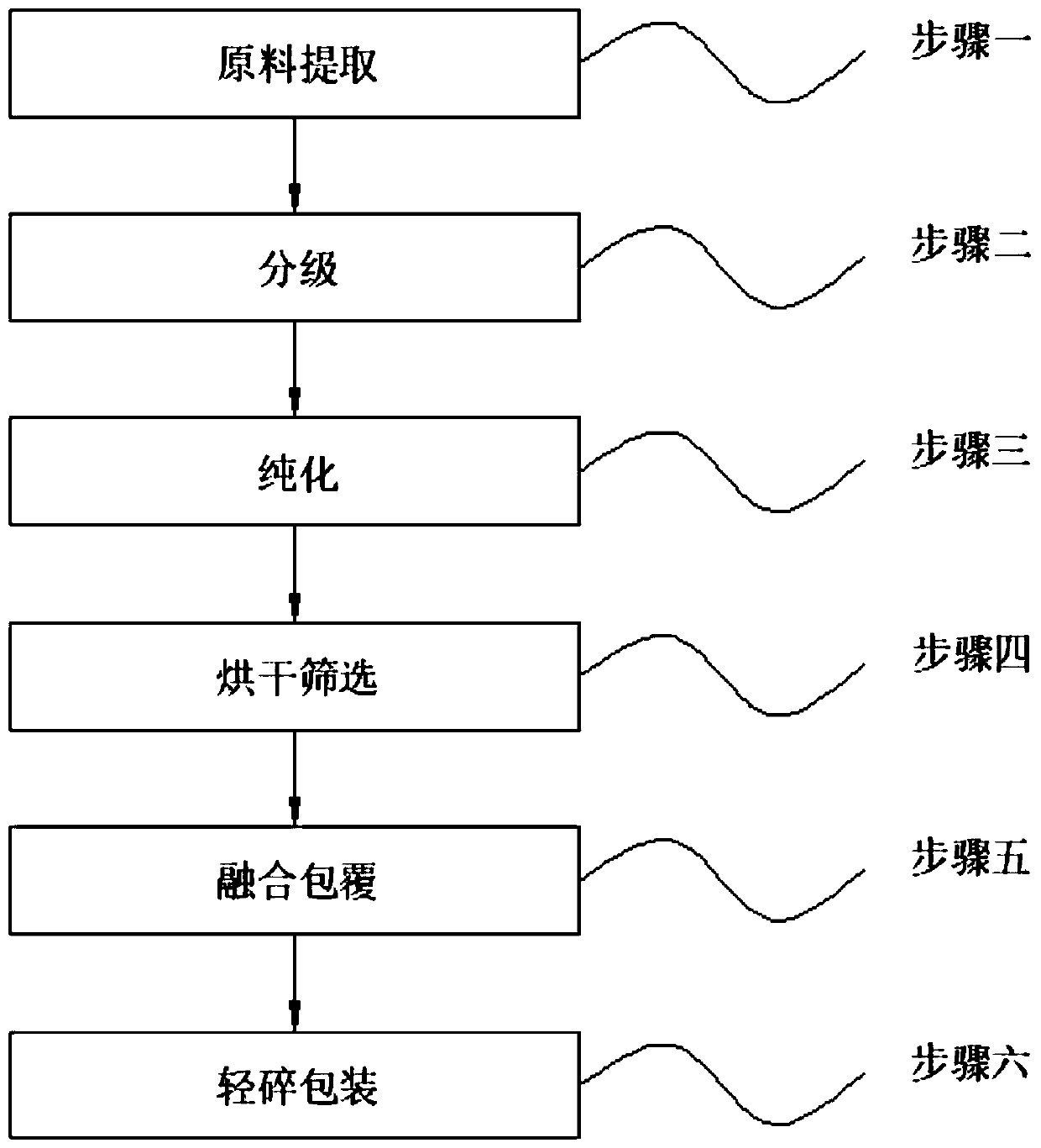

[0025] A method for preparing a graphite negative electrode material, comprising the following steps: Step 1, raw material extraction; Step 2, classification; Step 3, purification; Step 4, drying and screening; Step 5, fusion coating; Step 6, lightly crushed packaging;

[0026] In the above-mentioned step 1, the light and heavy minerals are separated through the spiral chute. After the ore slurry is fed into the spiral chute, the ore particles rotate downward along the trough in the ore slurry, and are affected by gravity, friction and water flow. The particle shape and specific gravity are separated. After the separation, the tailings, that is, light minerals, are coarsely crushed by a jaw crusher, and then the coarsely crushed ore particles are finely crushed by a hammer crusher, and the finely crushed ore particles are ball milled by a ball mill. , and then carry out flotation treatment to the ore particles through the flotation machine, and the ore particles after flotation...

Embodiment 2

[0033] A method for preparing a graphite negative electrode material, comprising the following steps: Step 1, raw material extraction; Step 2, classification; Step 3, purification; Step 4, drying and screening; Step 5, fusion coating; Step 6, lightly crushed packaging;

[0034] In the above-mentioned step 1, the light and heavy minerals are separated through the spiral chute. After the ore slurry is fed into the spiral chute, the ore particles rotate downward along the trough in the ore slurry, and are affected by gravity, friction and water flow. The particle shape and specific gravity are separated. After the separation, the tailings, that is, light minerals, are coarsely crushed by a jaw crusher, and then the coarsely crushed ore particles are finely crushed by a hammer crusher, and the finely crushed ore particles are ball milled by a ball mill. , and then carry out flotation treatment to the ore particles through the flotation machine, and the ore particles after flotation...

Embodiment 3

[0041] A method for preparing a graphite negative electrode material, comprising the following steps: Step 1, raw material extraction; Step 2, classification; Step 3, purification; Step 4, drying and screening; Step 5, fusion coating; Step 6, lightly crushed packaging;

[0042]In the above-mentioned step 1, the light and heavy minerals are separated through the spiral chute. After the ore slurry is fed into the spiral chute, the ore particles rotate downward along the trough in the ore slurry, and are affected by gravity, friction and water flow. The particle shape and specific gravity are separated. After the separation, the tailings, that is, light minerals, are coarsely crushed by a jaw crusher, and then the coarsely crushed ore particles are finely crushed by a hammer crusher, and the finely crushed ore particles are ball milled by a ball mill. , and then carry out flotation treatment to the ore particles through the flotation machine, and the ore particles after flotation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com