Straw smashing and recovering device for agricultural machinery

A straw crushing and recycling device technology, applied in the field of agricultural machinery, can solve the problems of reducing farmers' enthusiasm for straw recycling, reducing farmers' economic benefits, increasing transportation costs, etc., achieving the effects of reducing transportation costs, safe and convenient use, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

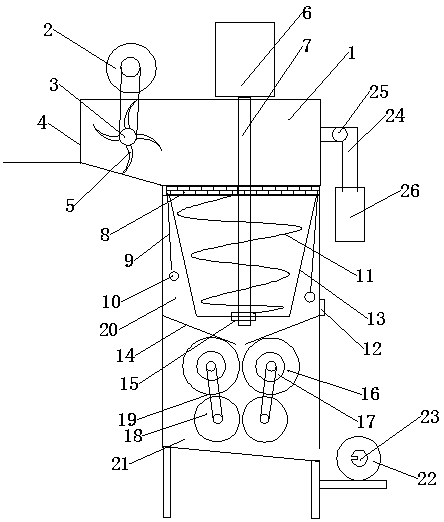

[0017] Such as figure 1 As shown, a straw crushing and recycling device for agricultural machinery includes a cutting chamber 1, a crushing chamber 20 and an extrusion chamber 21, the left side of the cutting chamber 1 is provided with a feed port 4, and the cutting chamber 1 A cutting motor 2 is fixedly arranged on the top of the cutting chamber 1, and a cutting shaft 3 is jointly arranged on the front and rear walls of the cutting chamber 1. A cutting knife 5 is arranged on the outside of the cutting shaft 3. The cutting shaft 3 and the cutting motor 2 The output end is connected by a belt 19, a crushing chamber 20 is arranged on the right side of the cutting chamber 1, a crushing motor 6 is fixedly arranged above the crushing chamber 20, and a rotating rod is arranged below the crushing motor 6 7. The rotating rod 7 is provided with a fixed seat 15, and the fixed seat 15 is fixedly connected with a filter screen 13, and a wear-resistant ring 8 is arranged around the upper e...

Embodiment 2

[0020] Such as figure 1 As shown, a straw crushing and recycling device for agricultural machinery includes a cutting chamber 1, a crushing chamber 20 and an extrusion chamber 21, the left side of the cutting chamber 1 is provided with a feed port 4, and the cutting chamber 1 A cutting motor 2 is fixedly arranged on the top of the cutting chamber 1, and a cutting shaft 3 is jointly arranged on the front and rear walls of the cutting chamber 1. A cutting knife 5 is arranged on the outside of the cutting shaft 3. The cutting shaft 3 and the cutting motor 2 The output end is connected by a belt 19, a crushing chamber 20 is arranged on the right side of the cutting chamber 1, a crushing motor 6 is fixedly arranged above the crushing chamber 20, and a rotating rod is arranged below the crushing motor 6 7. The rotating rod 7 is provided with a fixed seat 15, and the fixed seat 15 is fixedly connected with a filter screen 13, and a wear-resistant ring 8 is arranged around the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com