Method and system for treating waste gas containing ammonia and methane

A technology for treating gas and waste gas, applied in chemical instruments and methods, separation methods, air quality improvement, etc., can solve problems such as efficient removal of NH, and achieve the effect of improving removal efficiency, stabilizing waste gas purification rate, and ensuring waste gas purification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

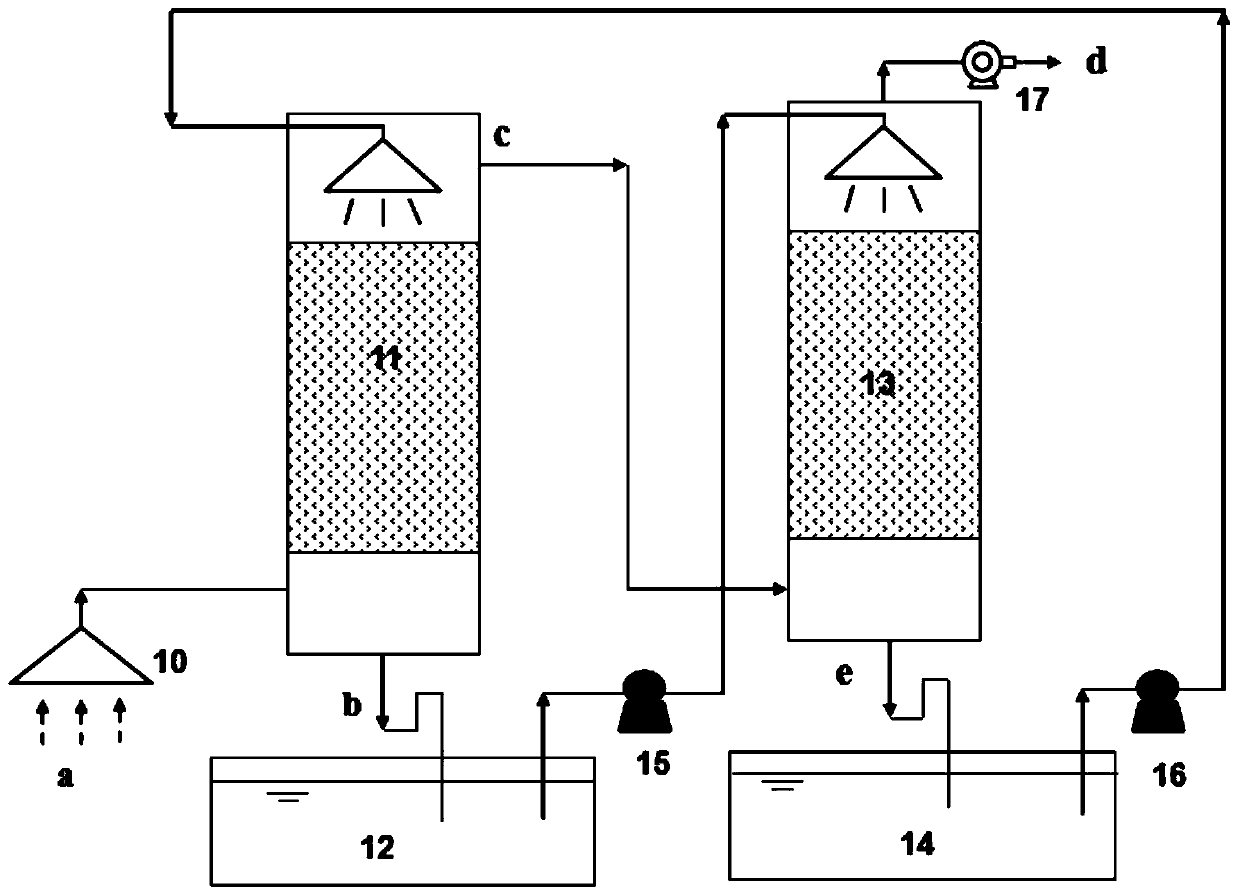

[0048] The system used in the embodiment of the present invention to deal with waste gas containing ammonia and methane, such as figure 1 As shown, it includes an induced draft fan 10, a first biological trickling filter tower 11 connected to the fan, a first nutrient solution storage tank 12 arranged at the bottom of the first biological trickling filter tower 11 and communicating with the bottom of the first biological trickling filter tower 11, The second biological trickling filter tower 13 connected to the gas outlet of the first biological trickling filter tower 11, the second nutrient solution storage tank 14 that is arranged at the bottom of the second biological trickling filter tower 13 and communicates with the bottom of the second biological trickling filter tower 13, The air outlet of the second biological trickling filter tower 13 is provided with a suction fan 17 .

[0049] Wherein, the liquid outlet of the first nutrient solution storage tank 12 is connected wi...

Embodiment 2

[0072] The first bio-trickling filter tower and the second bio-trickling filter tower packing are replaced by Bacillus aerobic denitrifying bacteria, and the rest are the same as in Example 1. The operating results show that the first Biotrickling filter 11 on NH 3 The purification efficiency can reach 90-92% stably, and the second biological trickling filter tower 13 is for CH 4 The purification efficiency can reach 85-87% stably, NO in the second nutrient solution storage tank 14 3 - and concentration of NO 2 - The concentration is 3.5-4.9mg / L.

Embodiment 3

[0074] The CuFe-LDHs modified zeolite in the first biological trickling filter tower and the second biological trickling filter tower filler is replaced by ZnFe-LDHs modified zeolite of equal content, and the rest are the same as in Example 1. The operation results show that the first biological Trickling filter 11 on NH 3 The purification efficiency can reach 91-93% stably, the second biotrickling filter tower 13 for CH 4 The purification efficiency can reach 85-86% stably, and the NO in the second nutrient solution storage tank 14 3 - and concentration of NO 2 - The concentration is 2.2-3.4mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com