MXene/natural rubber flexible composite film and preparation method thereof

A natural rubber and composite film technology, applied in the field of MXene/natural rubber flexible composite film and its preparation, can solve the problems of poor mechanical properties, complicated process, poor environmental friendliness, etc., and achieve low cost, broad application prospects, and excellent flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Ti 3 C 2 The preparation of the flexible composite film of natural rubber, the method is as follows:

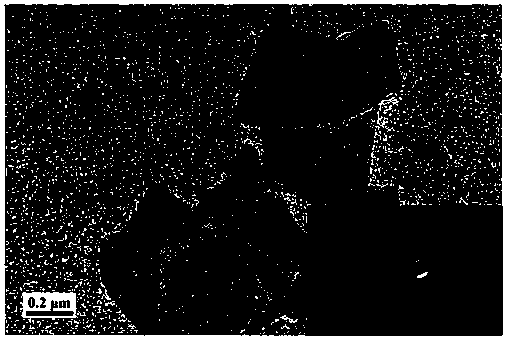

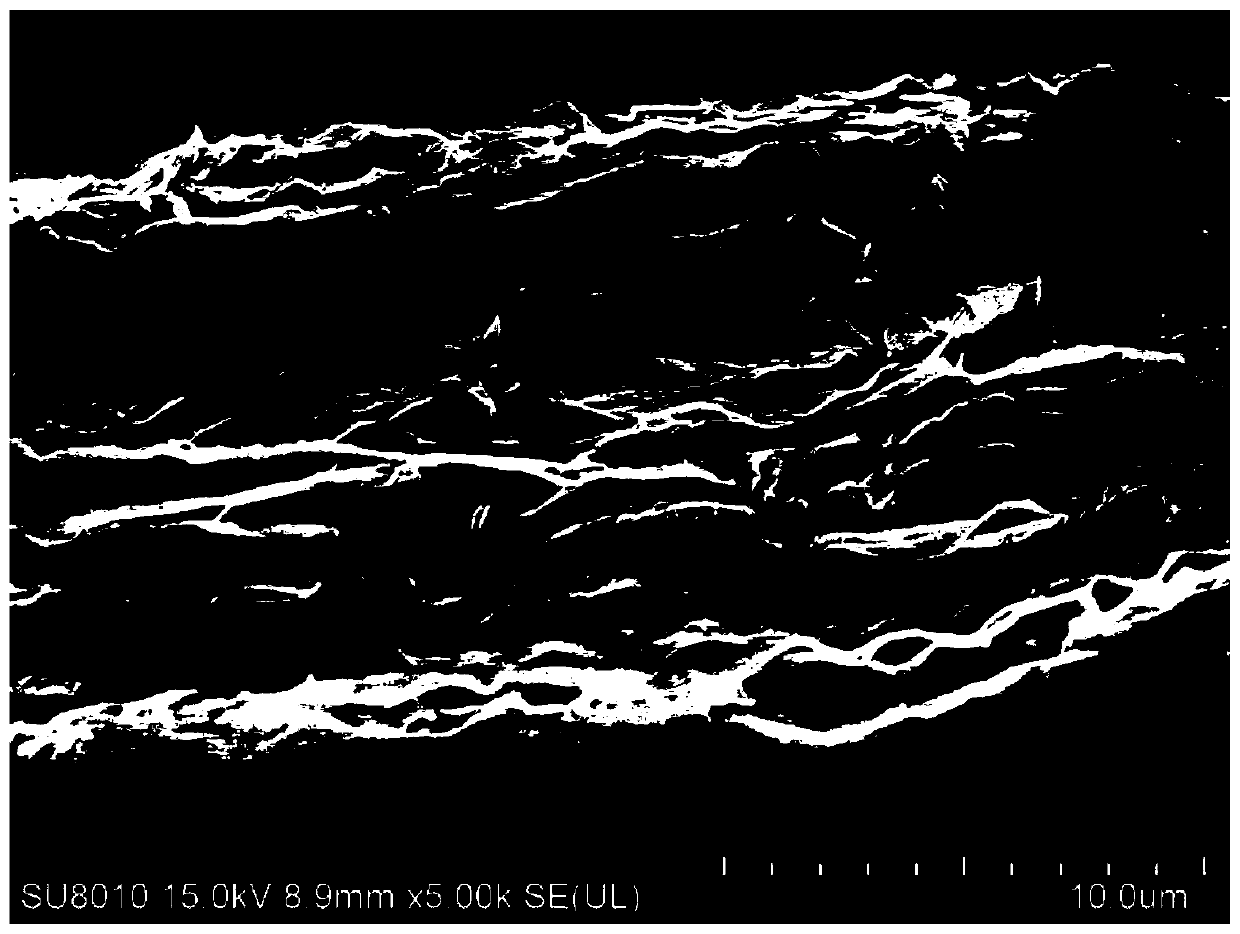

[0031] 1) Take 0.5g Ti 3 AlC 2 Put 0.5g lithium fluoride in a plastic beaker, add 10mL hydrochloric acid with a concentration of 7mol / L, stir and react at 30°C for 36h, the stirring speed is 400rpm, after the reaction is completed, it is centrifuged repeatedly, washed until the pH is 6, and dried to obtain Ti 3 C 2 precipitation.

[0032] 2) Take the Ti obtained in step 1) 3 C 2 Precipitate 0.2g, disperse in 40mL deionized water, ultrasonicate at 0°C for 30min, ultrasonic power is 100W, then centrifuge at 4000rpm for 5min, remove the precipitate, take the supernatant to obtain Ti 3 C 2 nanosheet suspension.

[0033] 3) with the Ti obtained in step 2) 3 C 2 Prepared as a 2mg / mL suspension, natural rubber as a 2mg / mL emulsion, according to Ti 3 C 2 The volume ratio of nanosheet suspension and natural rubber emulsion is 9:1 to prepare a mixed solution. Ultra...

Embodiment 2

[0037] Ti 3 C 2 The preparation of the flexible composite film of natural rubber, the method is as follows:

[0038] 1) Take 0.5g Ti 3 AlC 2 Put 0.5g lithium fluoride in a plastic beaker, add 11mL of hydrochloric acid with a concentration of 8mol / L, stir and react at 35°C for 42h, the stirring speed is 450rpm, after the reaction, centrifuge repeatedly, wash until the pH is 6.5, and dry to obtain Ti 3 C 2 precipitation.

[0039] 2) Take the Ti obtained in step 1) 3 C 2 Precipitate 0.2g, disperse in 45mL deionized water, sonicate at 1°C for 40min, ultrasonic power is 150W, then centrifuge at 4500rpm for 10min, remove the precipitate, take the supernatant to obtain Ti 3 C 2 nanosheet suspension.

[0040] 3) with the Ti obtained in step 2) 3 C 2 Prepared as a 2mg / mL suspension, natural rubber as a 2mg / mL emulsion, according to Ti 3 C 2 The volume ratio of nanosheet suspension and natural rubber emulsion is 8:2 to prepare a mixed solution. Ultrasound at 1°C for 15 min...

Embodiment 3

[0043] Ti 3 C 2 The preparation of the flexible composite film of natural rubber, the method is as follows:

[0044] 1) Take 0.5g Ti 3 AlC 2 Put 0.5g lithium fluoride in a plastic beaker, add 12mL of hydrochloric acid with a concentration of 9mol / L, stir and react at 40°C for 48h, the stirring speed is 500rpm, after the reaction, centrifuge repeatedly, wash until the pH is 7, and dry to obtain Ti 3 C 2 precipitation.

[0045] 2) Take the Ti obtained in step 1) 3 C 2 Precipitate 0.2g, disperse in 50mL deionized water, ultrasonicate at 2°C for 50min, ultrasonic power is 200W, then centrifuge at 5000rpm for 15min, remove the precipitate, take the supernatant to obtain Ti 3 C 2 nanosheet suspension.

[0046] 3) with the Ti obtained in step 2) 3 C 2 Prepared as a 2mg / mL suspension, natural rubber as a 2mg / mL emulsion, according to Ti 3 C 2 The volume ratio of nanosheet suspension and natural rubber emulsion is 6:4 to prepare a mixed solution. Ultrasound at 2°C for 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com