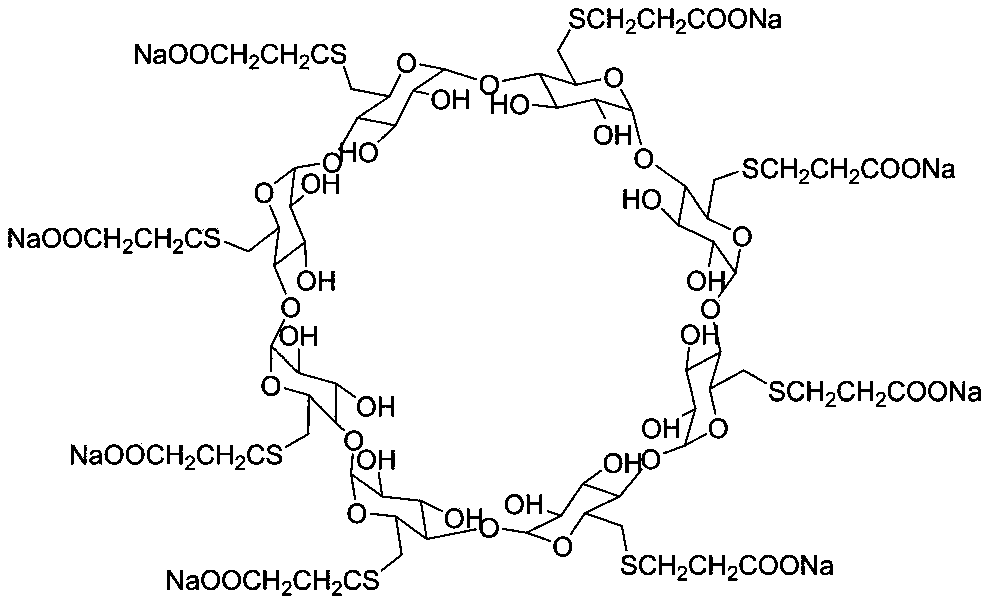

Preparation method of sugammadex sodium

A technology of sugammadex sodium and cyclodextrin, which is applied in the preparation field of sugammadex sodium, can solve the problems of low conversion rate and many impurities, and achieves a simple refining process, simple operation and few by-products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

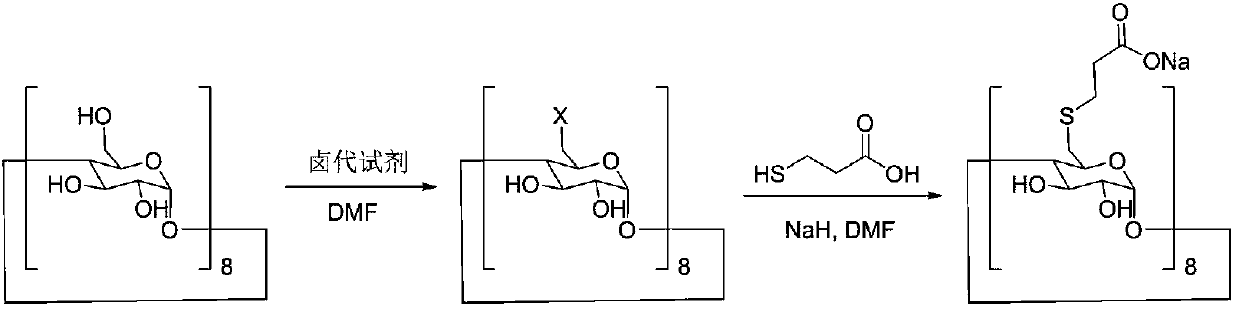

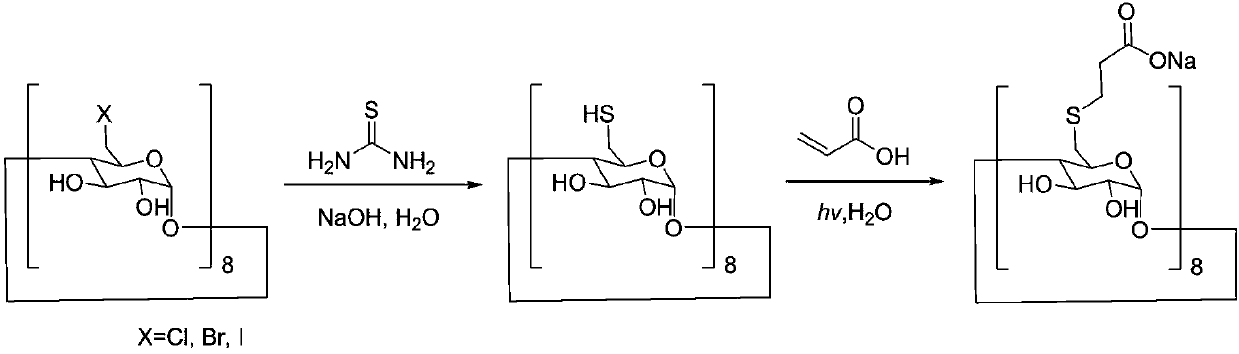

Method used

Image

Examples

Embodiment 1

[0057] The synthesis of embodiment 1 intermediate I

[0058] Add 50.00g (34.63mmol) of 6-perdeoxy-6-perchloro-γ-cyclodextrin and 43.21g (553.97mmol) of sodium sulfide into 350mL DMF, stir and react at 90°C for 18h, then pour the reaction liquid into In 3.5L of purified water, adjust the pH to 2-3 with 10% dilute hydrochloric acid while stirring, and filter the filter cake with suction, add the filter cake to 560 mL of purified water and raise the temperature to 60°C for beating for 2 hours, filter with suction to obtain a solid product, and vacuum-dry at 50°C After 12 hours, a white solid was obtained, namely 6-perdeoxy-6-permercapto-γ-cyclodextrin, with a yield of 95.60%, HPLC: 99.10%.

Embodiment 2

[0059] The synthesis of embodiment 2 intermediate I

[0060] Add 50.00g (27.78mmol) of 6-perdeoxy-6-perbromo-γ-cyclodextrin and 34.67g (444.49mmol) of sodium sulfide into 350mL DMF, stir and react at 80°C for 14h, then pour the reaction liquid into In 3.5L of purified water, adjust the pH to 2-3 with 10% dilute hydrochloric acid while stirring, and filter the filter cake with suction, add the filter cake to 600 mL of purified water and raise the temperature to 60°C for beating for 2 hours, filter with suction to obtain a solid product, and dry it in vacuum at 50°C After 12 hours, a white solid was obtained, namely 6-perdeoxy-6-permercapto-γ-cyclodextrin, with a yield of 98.56%, HPLC: 99.60%.

Embodiment 3

[0061] The synthesis of embodiment 3 intermediate I

[0062] Add 50.00g (27.78mmol) of 6-perdeoxy-6-perbromo-γ-cyclodextrin and 34.67g (444.49mmol) of sodium sulfide into 350mL of dimethyl sulfoxide, and stir and react at 80°C for 14h. Pour the reaction solution into 3.5L of purified water, adjust the pH to 2-3 with 10% dilute hydrochloric acid while stirring, and filter with suction to obtain a filter cake, add the filter cake to 600mL of purified water and raise the temperature to 60°C for beating for 2 hours, and filter with suction to obtain a solid product , dried under vacuum at 50°C for 12 hours to obtain a white solid, namely 6-perdeoxy-6-permercapto-γ-cyclodextrin, with a yield of 96.01%, HPLC: 99.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com