Rapid cooling and curing 3D printing material and preparation method thereof

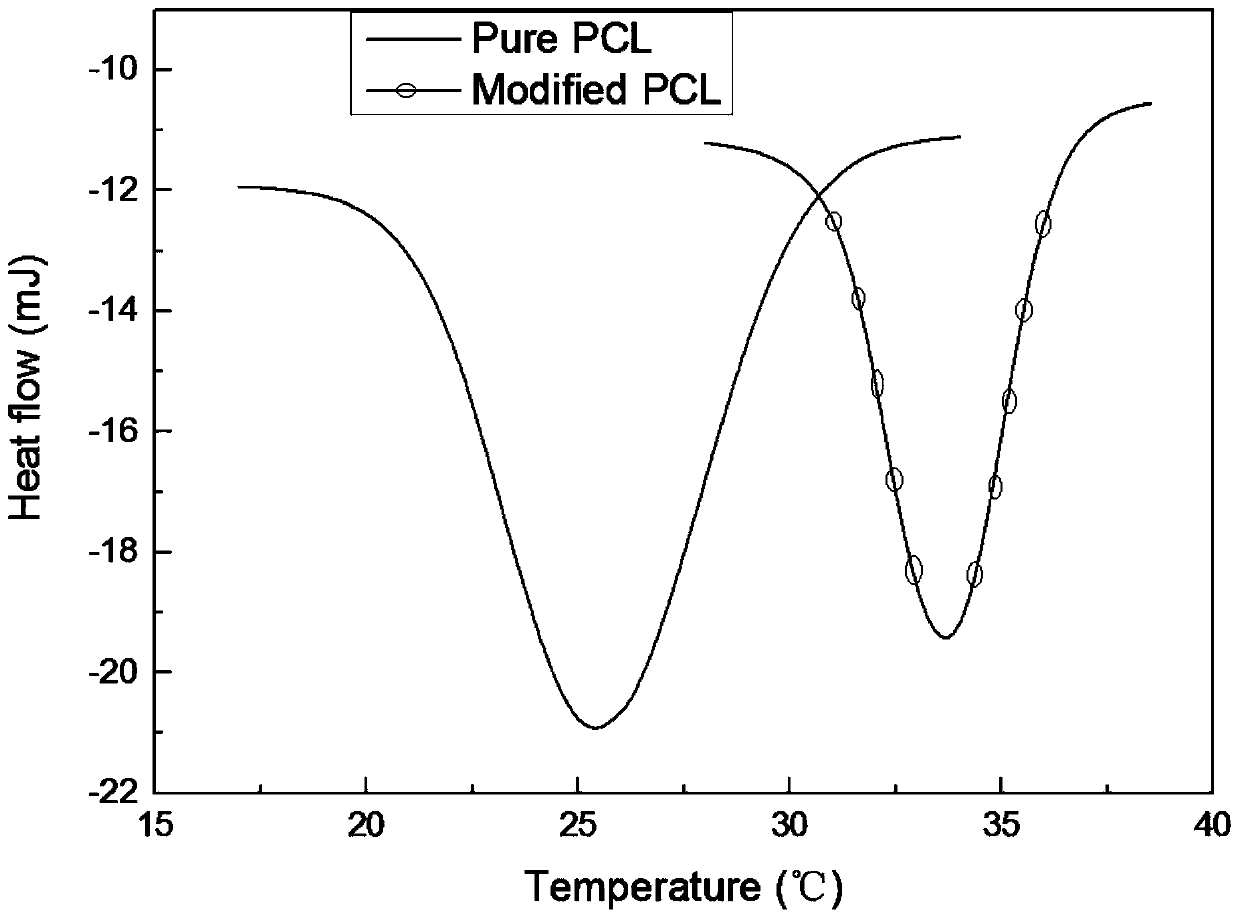

A 3D printing and rapid cooling technology, which is applied in the field of 3D printing materials, can solve the problems of shortening the cooling and solidification time of PCL and the difficulties of supports, and achieves the effects of fast cooling and solidification rate, high product precision and decreased melt index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

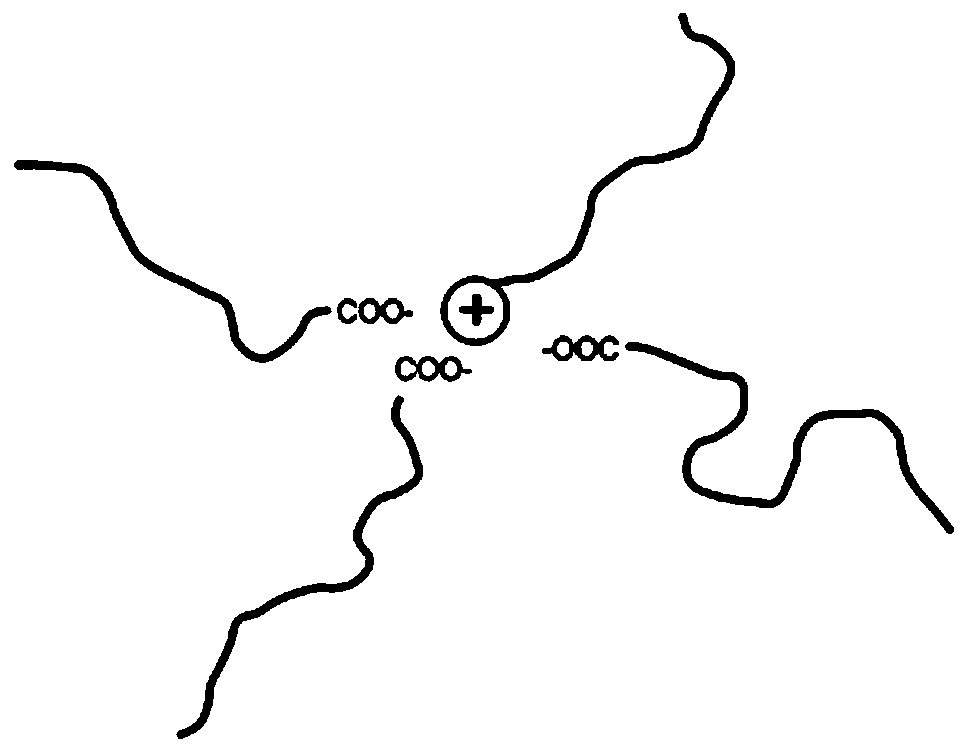

[0036] This embodiment discloses a method for preparing a rapidly cooled and solidified 3D printing material, which includes uniformly mixing 70 parts of polycaprolactone with 3.5 parts of ethylene-sodium methacrylate and sodium acrylate to obtain a first mixture, the first mixture Melt and granulate through twin-screw extruder, control the temperature at 80-120°C to obtain the first masterbatch, the specific temperature of each stage is 80°C, 95°C, 110°C, 120°C, 120°C, 110°C, 95°C , 80°C; the first masterbatch is mixed with 23.8 parts of PBAT elastomer, 1.4 parts of talcum powder and titanium dioxide mixture, and 1.3 parts of antioxidant 1010 to obtain the second mixture,

[0037] The second mixture is melted and granulated by a twin-screw extruder, and the temperature is controlled at 80-120°C to obtain the second master batch. The specific temperatures of each stage are 82°C, 95°C, 110°C, 120°C, 120°C, 110°C, 95°C, 82°C; the second masterbatch is put into a single-screw ext...

Embodiment 2

[0041] This embodiment discloses a method for preparing a rapidly cooled and solidified 3D printing material, which includes uniformly mixing 87.8 parts of polycaprolactone with 0.8 parts of ethylene-sodium methacrylate and sodium acrylate to obtain a first mixture, and the first mixture is subjected to Twin-screw extruder melt granulation, control the temperature at 80-120°C to obtain the first masterbatch, the first masterbatch and 8.8 parts of PBAT elastomer, 1.6 parts of the mixture of talcum powder and titanium dioxide and 1 part of antioxidant 168 to obtain the second mixture evenly, the second mixture is melted and granulated through a twin-screw extruder, and the temperature is controlled at 80-120°C to obtain the second masterbatch, and the second masterbatch is fed into the single-screw extruder Wire drawing treatment, controlling the wire forming temperature to 85-110°C to obtain 3D printing materials.

[0042] Further measurement of the tensile strength of the 3D pri...

Embodiment 3

[0044] This embodiment discloses a method for preparing a rapidly cooling and solidifying 3D printing material, which includes uniformly mixing 87.5 parts of polycaprolactone and 1.2 parts of ethylene-sodium methacrylate to obtain a first mixture, and the first mixture is extruded by a twin-screw Exit the machine for melting and granulation, control the temperature at 80-120°C to obtain the first masterbatch, the first masterbatch and 8.8 parts of TPU, 1.4 parts of montmorillonite and mica nucleating agent with a mass ratio of 3:2 and 1.1 parts The mixture of antioxidant 1010 and antioxidant 168 with a mass ratio of 1:2 was uniformly mixed to obtain the second mixture. The second mixture was melted and granulated through a twin-screw extruder, and the temperature was controlled at 80-120°C to obtain the second mixture. The masterbatch, the second masterbatch is put into a single-screw extruder and subjected to wire drawing treatment, and the molding temperature of the wire rod ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| crystallization time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com