A powder spraying tower for processing chicken essence

A technology for spraying powder and chicken is applied in the field of powder spraying tower for chicken flavor processing, which can solve the problems of increased labor intensity of staff, low degree of powder granulation, repeated processing once, etc., so as to avoid precipitation of insoluble substances and reduce consumption. Electrical equipment to ensure the effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

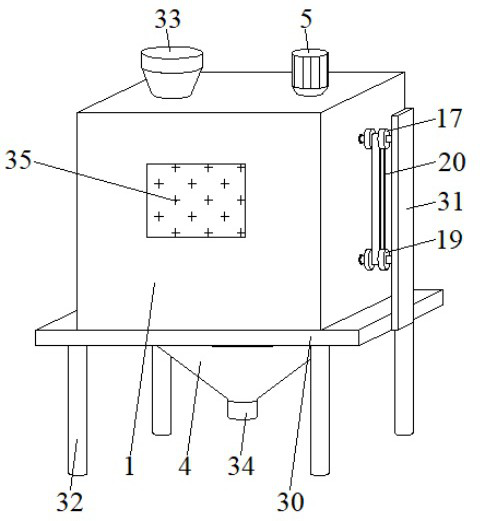

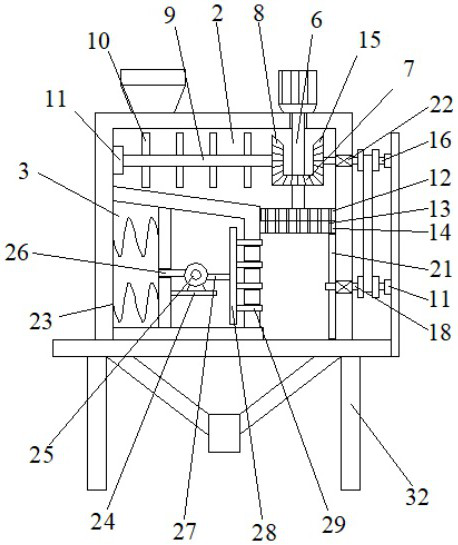

[0024] see Figure 1-2 According to an embodiment of the present invention, a powder spraying tower for processing chicken essence includes a powder spraying tower 1, and the powder spraying tower 1 includes an essential oil temporary storage room 2, a heating chamber 3 and a powder hopper 4, and the powder spraying tower 1, an essential oil temporary storage room 2 is arranged on the top, and a heating chamber 3 is arranged on one side of the essential oil temporary storage room 2, and a powder funnel 4 is arranged at the bottom of the powder spraying tower 1, and a powder funnel 4 is arranged at the top of the powder spraying tower 1. One side is provided with motor 5, and the output end of described motor 5 is connected with output shaft 6, and the other end of described output shaft 6 passes in the described essential oil temporary storage room 2, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com