Stepped fluidized bed gas distribution plate

A gas distribution plate and gas distribution technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of abrasion of internal components, low heat and mass transfer efficiency, and low operating elasticity, and reduce erosion and erosion. , The structure is simple and sturdy, and the effect of the movement is relaxed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

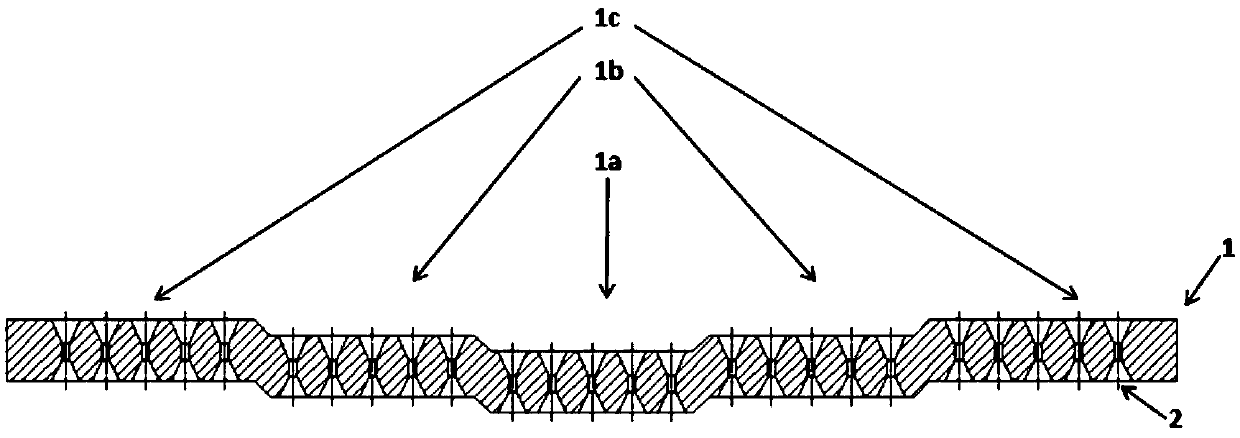

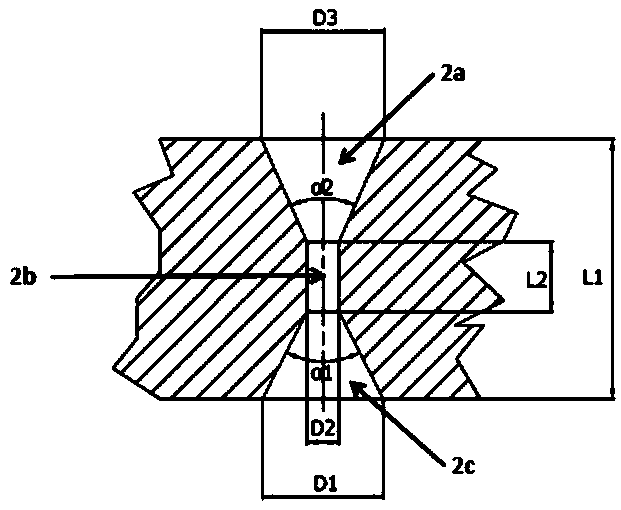

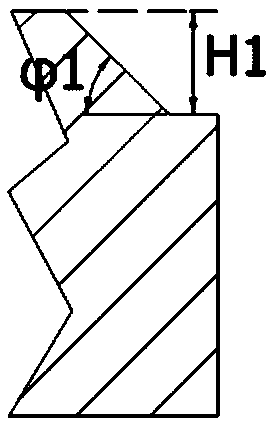

[0034] A pilot fluidized bed reactor with a diameter of 1 m and a height of 6 m is equipped with a gas distribution plate such as figure 1 and image 3 As shown, the central area 1a is a circular area located in the center of the distribution plate 1, accounting for 20% of the total area of the distribution plate; the main area 1b is a circular area, accounting for 60% of the total area of the distribution plate, and it passes through the central area 1a The inclined surface is connected, the thickness of the distribution plate is 30mm, the height difference H1 is 12mm, and the angle between the inclined surface and the horizontal plane of the central area is 60°; the wall area 1c is a circular area, accounting for 20% of the total area of the distribution plate, located on the outer edge of the distribution plate 1, and connected to the main body area 1b through an inclined surface, the height difference H1 is 30mm, the inclined surface and the main body The angle bet...

Embodiment 2

[0039] A pilot fluidized bed reactor with a diameter of 1 m and a height of 6 m is equipped with a gas distribution plate such as figure 1 and image 3 As shown, the central area 1a is a circular area located in the center of the distribution plate 1, accounting for 50% of the total area of the distribution plate; the main body area 1b is an annular area, accounting for 40% of the total area of the distribution plate, and it is the same as the central area 1a Connected by an inclined surface, the thickness of the distribution plate is 25mm, the height difference H1 is 10mm, and the angle between the inclined surface and the horizontal plane of the central area is 30°; the wall area 1c is a ring-shaped area, accounting for 10% of the total area of the distribution plate. The outer edge of the plate 1 is connected to the main area 1b through an inclined surface, the height difference H1 is 10mm, and the angle between the inclined surface and the horizontal plane of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com