PET composite material prepared from recycled PET plastic waste and application thereof

A technology of plastic waste and composite materials, which is applied in the field of PET plastic waste recycling, can solve the problems of difficult operation and low recycling efficiency, and achieve the effects of reducing pollution, high recycling, good mechanical properties and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

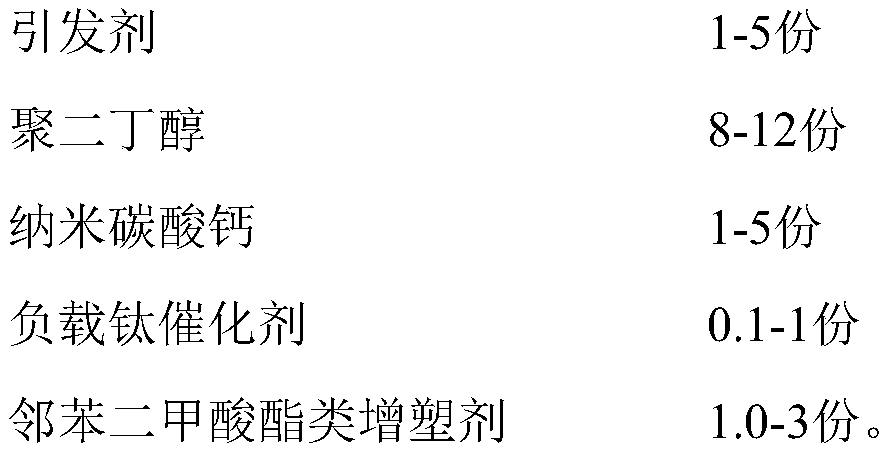

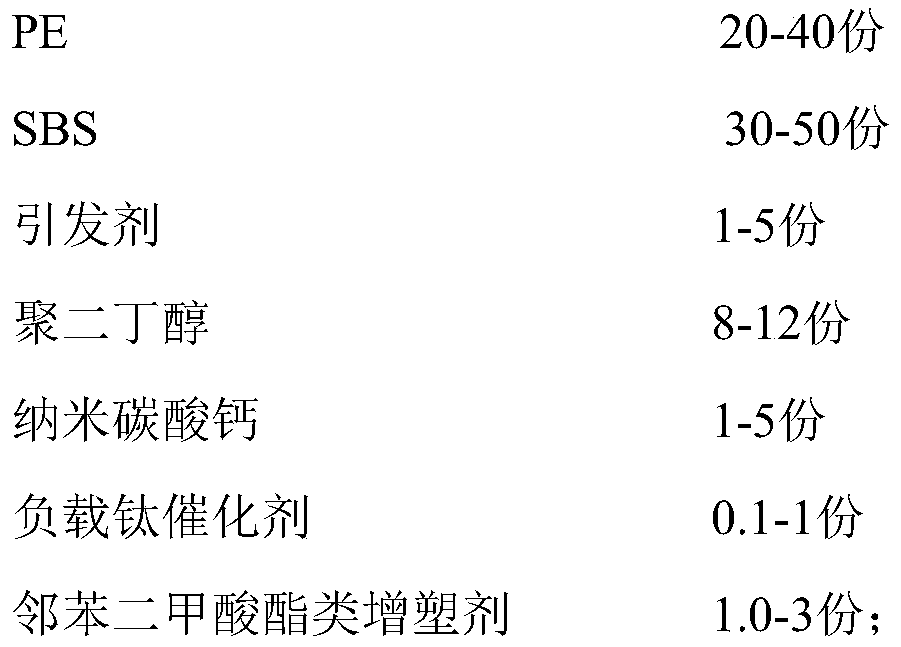

Method used

Image

Examples

Embodiment 1

[0034] A method for recycling PET plastic waste, comprising the steps of:

[0035] 1) Soak and wash the recovered waste PET plastics in clear water and chop them up, heat the chopped PET plastics to 90°C and cook for 20 minutes, and obtain PET plastic fragments after cooling for later use;

[0036] 2) Add the PET plastic fragments obtained in step 1) into a stirring device equipped with tetrahydrofuran, heat to 70°C, and stir for 60 minutes, then separate the PET plastic fragments from tetrahydrofuran, wash them with clean water, and set aside;

[0037] 3) Soak the PET plastic fragments treated in step 2) with sodium hydroxide with a concentration of 0.2mol / L for 2 hours, then soak and wash them with hydrochloric acid solution with a concentration of 0.2mol / L for 1 hour, rinse them with clean water, and dry them for later use , the drying temperature is 80°C;

[0038] 4) Put the PET plastic fragments dried in step 3) into the melting equipment and heat to 160°C to melt, then ...

Embodiment 2

[0058] A method for recycling PET plastic waste, comprising the steps of:

[0059] 1) Soak and wash the recovered waste PET plastics in clear water and then chop them up, heat the chopped PET plastics to 93°C for 25 minutes, and obtain PET plastic fragments after cooling for later use;

[0060] 2) Add the PET plastic fragments obtained in step 1) into a stirring device equipped with tetrahydrofuran, heat to 75°C, and stir for 75 minutes, then separate the PET plastic fragments from tetrahydrofuran, rinse them with clean water, and set aside;

[0061] 3) Soak the PET plastic fragments treated in step 2) with sodium hydroxide with a concentration of 0.25mol / L for 2.5h, then soak and wash with a hydrochloric acid solution with a concentration of 0.25mol / L for 5h, then rinse with clean water, and dry Dry for standby, the temperature during drying is 85°C;

[0062] 4) Put the PET plastic fragments dried in step 3) into the melting equipment and heat to 170°C to melt, then add the ...

Embodiment 3

[0082] A method for recycling PET plastic waste, comprising the steps of:

[0083] 1) Soak and wash the recovered waste PET plastics in clear water and chop them up, heat the chopped PET plastics to 95°C and cook for 30 minutes, and obtain PET plastic fragments after cooling for later use;

[0084] 2) Add the PET plastic fragments obtained in step 1) into a stirring device equipped with tetrahydrofuran, heat to 80° C., and stir for 90 minutes, then separate the PET plastic fragments from tetrahydrofuran, rinse them with clean water, and set aside;

[0085] 3) Soak the PET plastic fragments treated in step 2) with sodium hydroxide with a concentration of 0.3mol / L for 3 hours, then soak and wash them with hydrochloric acid solution with a concentration of 0.3mol / L for 2 hours, rinse them with clean water, and dry them for later use , the drying temperature is 90°C;

[0086] 4) Put the PET plastic fragments dried in step 3) into the melting equipment and heat to 180°C to melt, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com