Air bearing

An air bearing and bearing technology, applied in the direction of air cushion bearings, bearings, bearing components, etc., can solve the problems of easy wear of air bearings, low hardness of silicon carbide material, short service life, etc., and achieves low thermal expansion coefficient and oxidation resistance. The effect of strong performance and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

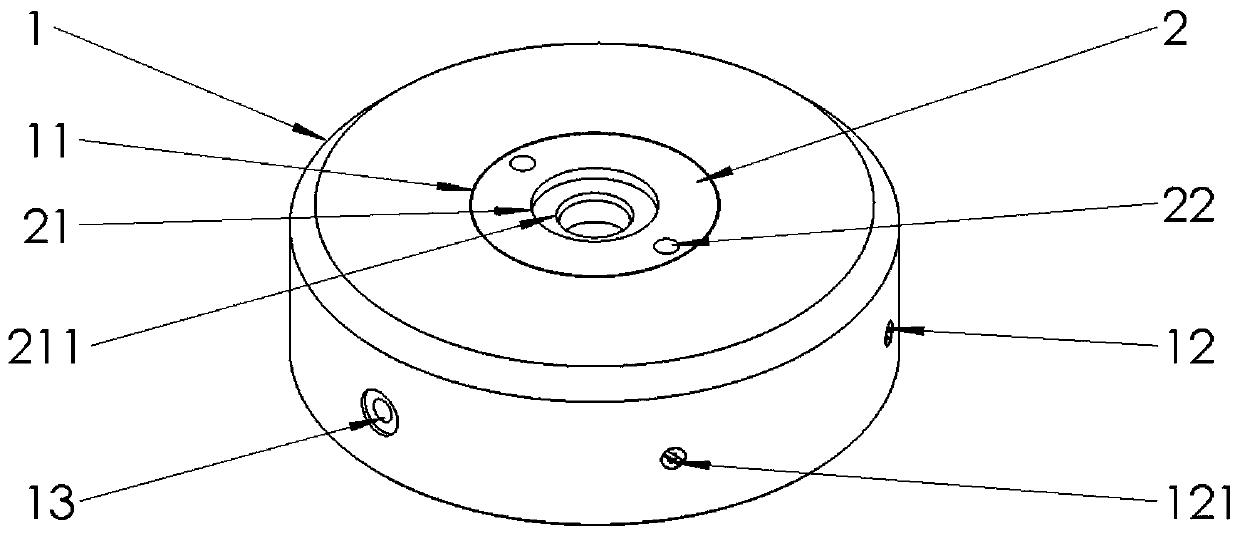

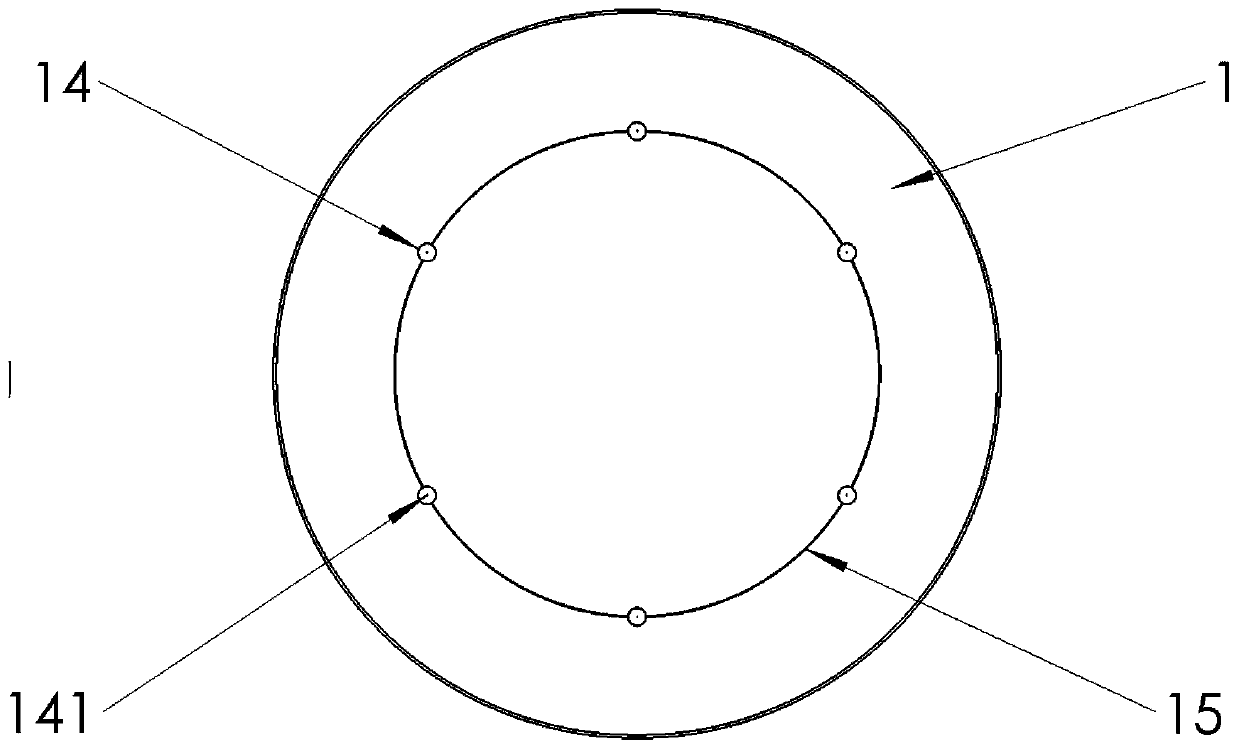

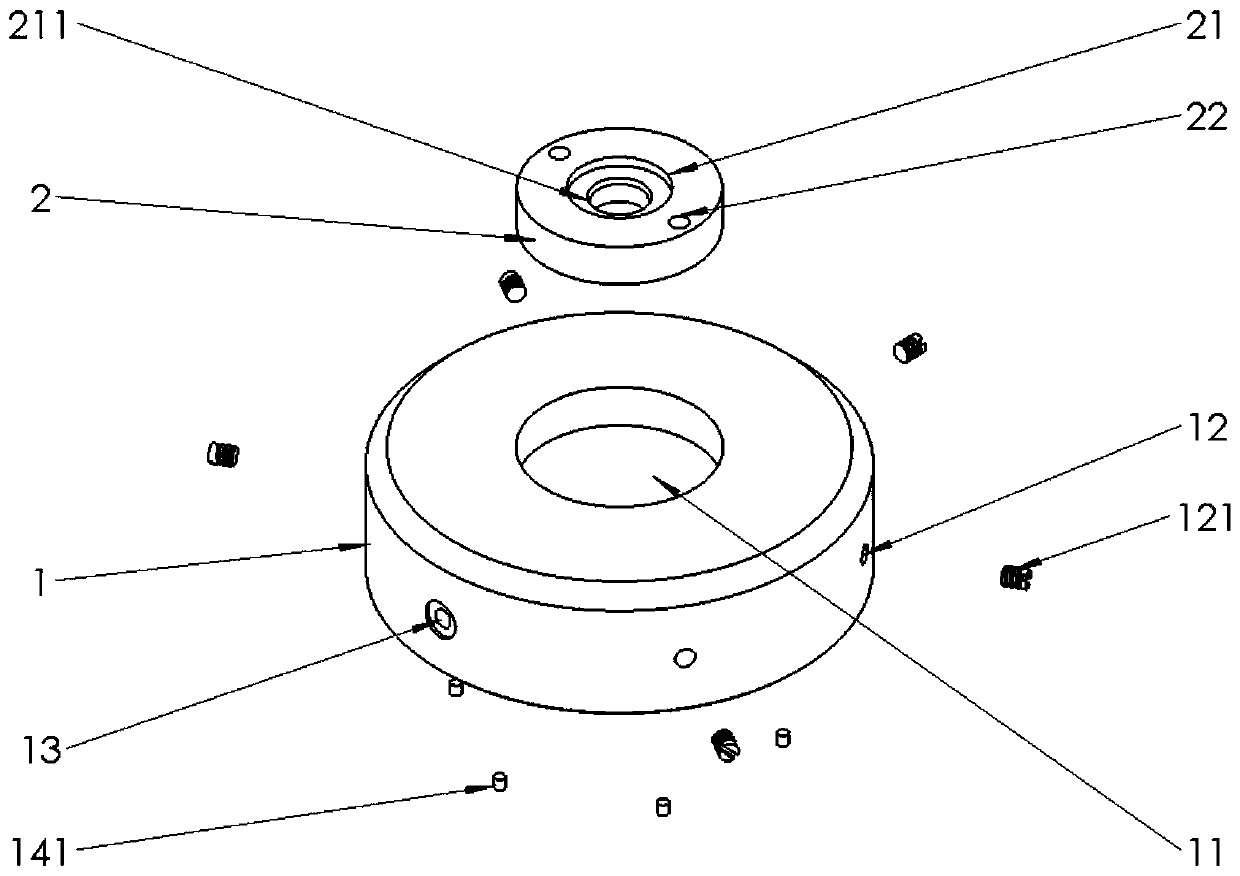

[0062] refer to Figure 1-Figure 4 , the present invention provides an air bearing, comprising a bearing body 1 and a pressure equalizing pad 2, the bearing body 1 is made of silicon carbide, the top of the bearing body 1 is provided with an inlaid hole 11, and the pressure equalizing pad 2 is placed In the inlay hole 11, and matched with the size of the inlay hole 11, the bearing body 1 is provided with an air passage 12 communicating with each other, and the side of the bearing body 1 has an air inlet 13 communicating with the air passage 12 , the bottom of the bearing body 1 is provided with an exhaust hole 14 communicating with the air channel 12 , and the pressure equalizing pad 2 is provided with an assembly hole 21 . The cross section of the bearing body 1 is circular, and the cross section of the inlay hole 11 is circular.

[0063] With the above scheme, the bearing body 1 is made of silicon carbide, which has strong oxidation resistance, good wear resistance, high ha...

Embodiment 2

[0085] The structure of this embodiment is substantially the same as that of Embodiment 1, and the same components are marked with the same reference numerals, the difference is that the pressure equalizing pad 2 and the bearing body 1 are fixedly connected by glue.

[0086] In a preferred implementation of this embodiment, the glue is made of epoxy resin material.

[0087] With the above solution, the glue is resistant to high temperature and also has the function of shock absorption, preventing the bearing body 1 from being damaged due to excessive impact.

Embodiment 3

[0089] The structure of the present embodiment is substantially the same as that of the first embodiment, and the same components use the same reference numerals, except that the diameter b of the orifice satisfies: b=0.15 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com