Preparation method of silicon substrate GaN-based epitaxial structure and epitaxial structure

An epitaxial structure, silicon substrate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of large lattice mismatch, high dislocation density of GaN materials, affecting LED luminous efficiency, etc., and achieve enhanced blocking effect. , the effect of reducing the barrier peak and reducing the valence band barrier difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

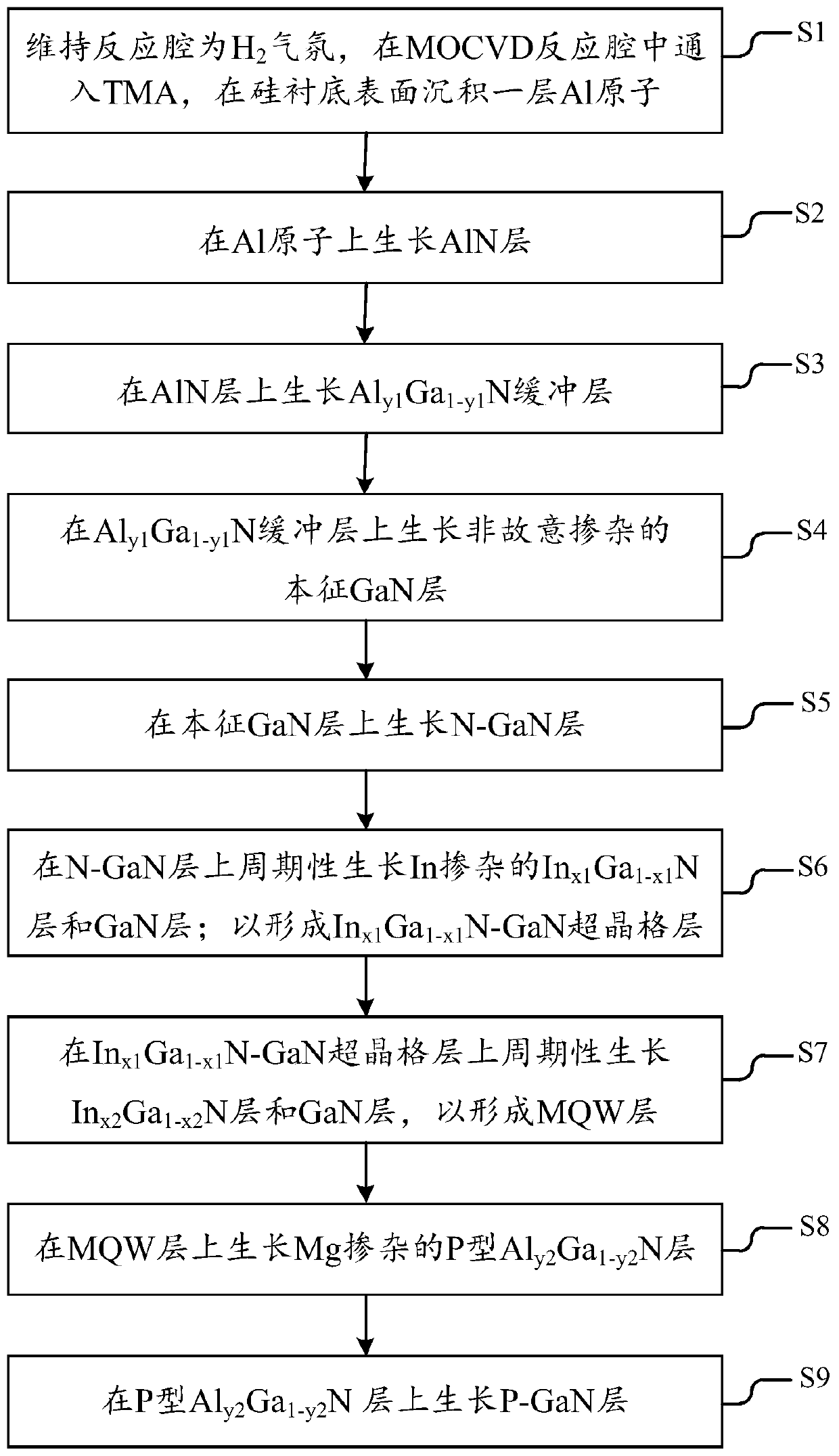

[0045] See figure 1 The present invention provides a method for preparing a GaN-based epitaxial structure on a silicon substrate, which includes the following steps:

[0046] S1: Maintain the reaction chamber as H 2 Atmosphere, pass TMA into the MOCVD reaction chamber, and deposit a layer of Al atoms on the surface of the silicon substrate;

[0047] Specifically, S1 includes:

[0048] S11: Maintain the temperature of the MOCVD reaction chamber at 1000-1100°C, the pressure at 50-200torr, and process the silicon substrate in a hydrogen atmosphere for 1 to 5 minutes;

[0049] Because there is a thin layer of SiO on the surface of the silicon substrate 2 , Using hydrogen at high temperature can remove oxygen atoms and other impurities on the surface of the substrate, laying a good foundation for the formation of a good epitaxial layer in the later stage.

[0050] S12: Maintain the temperature of the reaction chamber at 1100-1100°C and the pressure at 50-200 torr, pass trimethyl aluminum (TM...

Embodiment

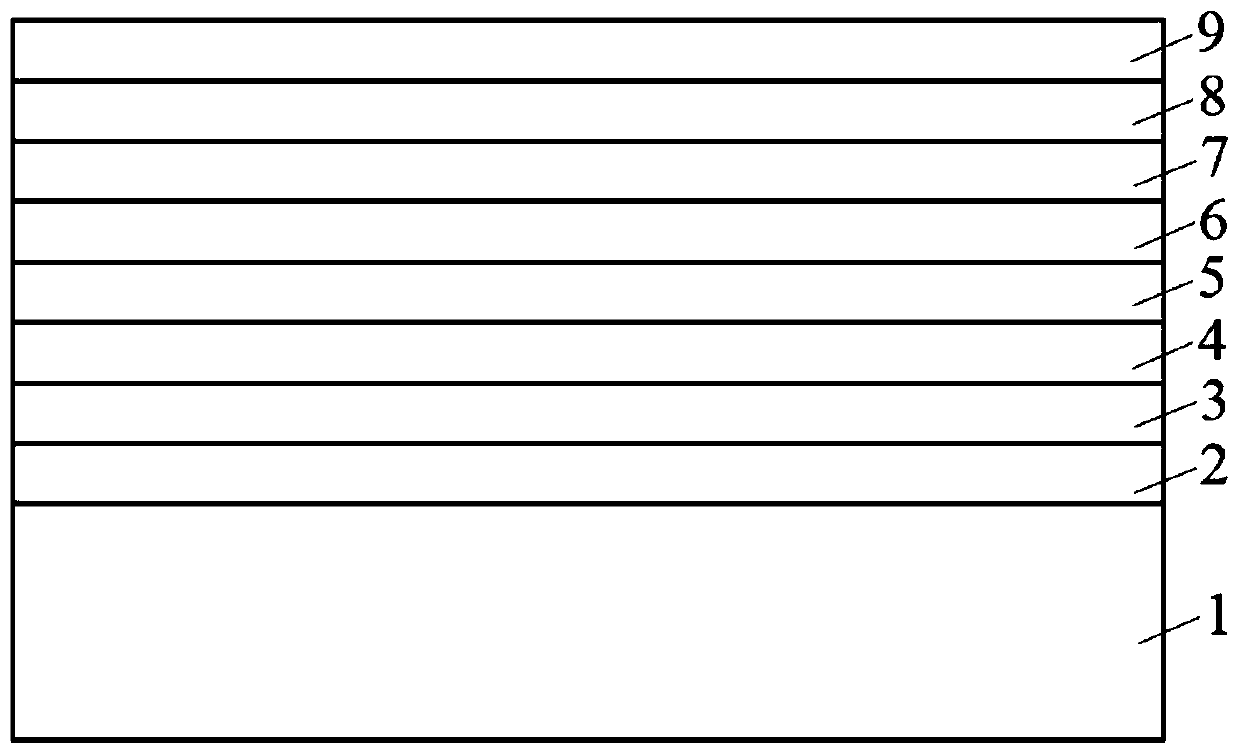

[0085] This embodiment provides a GaN-based epitaxial structure on a silicon substrate, and the preparation method thereof includes:

[0086] (1) Maintain the temperature of the MOCVD reaction chamber at 1050°C and the pressure at 150torr. 2 Process the silicon substrate for 2 minutes in an atmosphere;

[0087] (2) Maintain the temperature of the reaction chamber at 1050°C and the pressure at 150 torr, pass in TMA, and deposit a layer of Al atoms on the silicon substrate;

[0088] (3) Reduce the temperature of the reaction chamber to 980℃, the pressure to 100torr, and pass in NH 3 , TMA, grow AlN layer;

[0089] (4) Maintain the temperature of the reaction chamber at 980℃, the pressure at 100torr, and pass NH 3 , TMA and TMGa, growing Al with a thickness of 220nm y1 Ga 1-y1 N buffer layer; among them, the value of y1 ranges from 0.35 to 1; y1 decreases once with the increase of the thickness of the buffer layer;

[0090] (5) Maintain the temperature of the reaction chamber at 1080℃, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com