A kind of loudspeaker paper cone and its preparation method and application

A loudspeaker and paper cone technology, which is applied in the field of loudspeakers, can solve the problems of destroying the film-forming continuity of other paper additives, affecting the sound quality of the speaker, and the decline in the mechanical properties of the paper cone. It achieves strong electrostatic bonding, good water resistance, and low The effect of surface free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

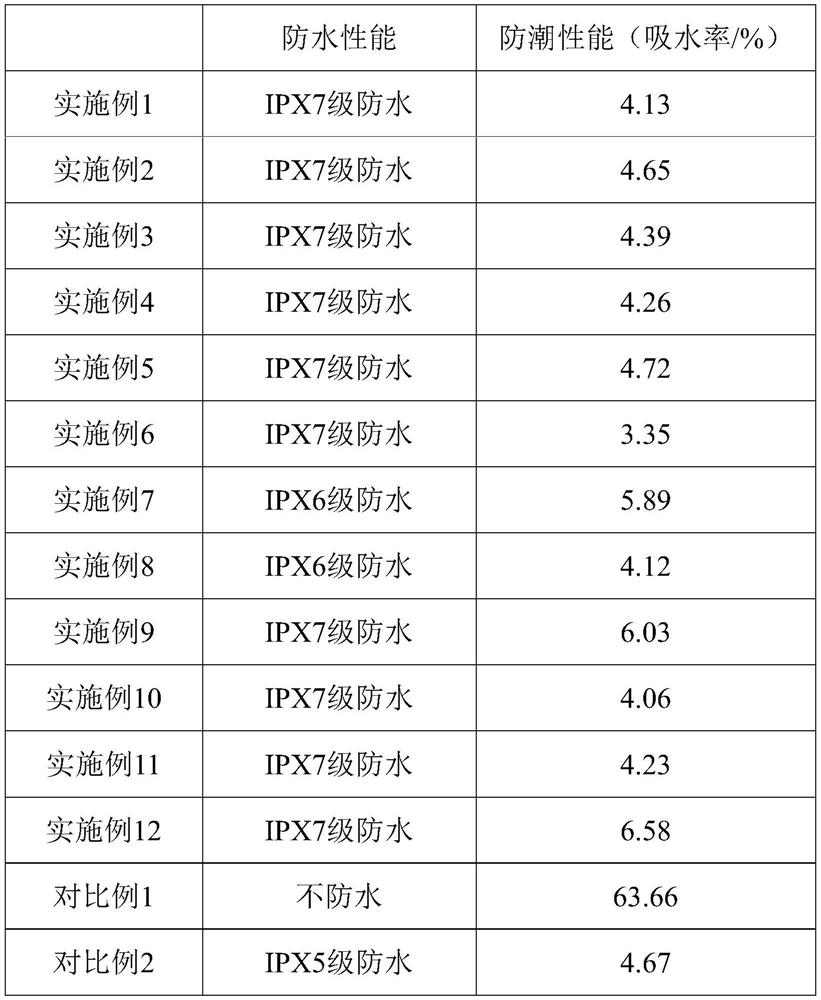

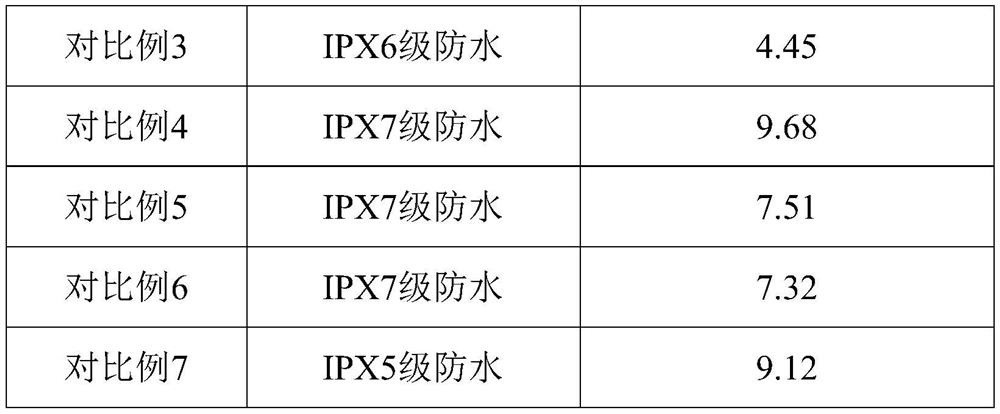

Examples

Embodiment 1

[0049] This embodiment provides a speaker paper pot, and the preparation method is as follows:

[0050] (1) Adding a cationic benzide emulsion to the pulp, adding the amount of 10%, stirring; stirring; 15 min, continues to add emulsified paraffin to the slurry, adding the amount of 2% of the ride of the right slurry, stir well, Get prefabricated slurry;

[0051] (2) The prefabricated slurry obtained by step (1) is passed through the pulp, hot press molding, and digestive to obtain the speaker paper pot.

Embodiment 2

[0053] This embodiment provides a speaker paper pot, and the preparation method is as follows:

[0054] (1) Adding a cationic benzide emulsion to the pulp, the amount is 5%, stirred; stirring; 15 min, continues to add emulsified paraffin to the slurry, and add amount of 5% of the quality of the right slurry, stir well. Get prefabricated slurry;

[0055] (2) The prefabricated slurry obtained by step (1) is passed through the pulp, hot press molding, and digestive to obtain the speaker paper pot.

Embodiment 3

[0057] This embodiment provides a speaker paper pot, and the preparation method is as follows:

[0058] (1) Adding a cationic benzide emulsion to the pulp, the amount is 7.5%, stirred; after 15 min, continue to add emulsified paraffin to the slurry, add amount of 3% of the quality slurry, stir well, Get prefabricated slurry;

[0059] (2) The prefabricated slurry obtained by step (1) is passed through the pulp, hot press molding, and digestive to obtain the speaker paper pot.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com