Exhaust cylinder and method for wet dust removal and purification

A technology of wet dust removal and exhaust stack, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, which can solve the problems of reducing the moisture content of flue gas, occupying a large area of equipment, and large investment at one time, so as to reduce The effect of occupying an area, improving dehydration efficiency, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First of all, it should be noted that the specific implementation of this embodiment relies on the gas supply system 10 and the combustion-supporting gas supply system 11 that can be independently controlled.

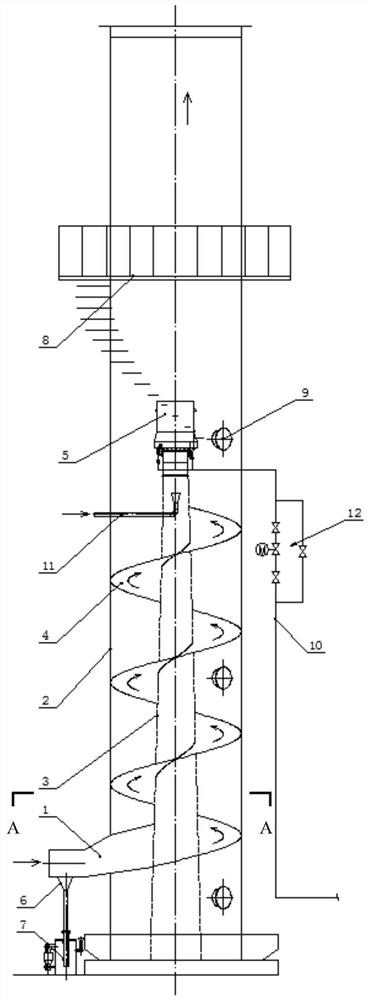

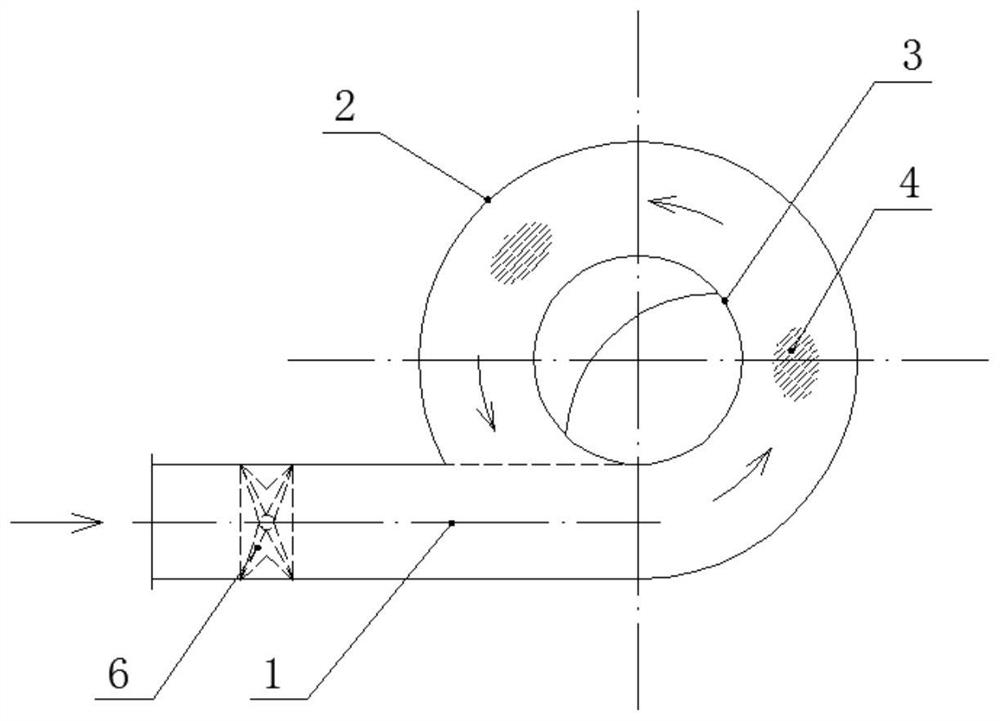

[0029] This embodiment discloses an exhaust cylinder for wet dust removal and purification, which includes a cylinder body 2, a core tube 3, a spiral partition 4, a heating mechanism and a water collecting funnel 6, and the core tube 3 is installed inside the cylinder body 2. A heating mechanism is installed on the top of the core tube 3, and the heating mechanism is used to heat the dehydrated flue gas. A water collecting funnel 6 is installed at the bottom of the exhaust tube body. There is a gap between the core tube 3 and the exhaust tube body. The spiral partition 4 is installed Between the cylinder body 2 and the core tube 3, a continuous spiral channel is formed, and the spiral channel is used to provide a centrifugal force channel to realize the gas-water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com