Laser welding method and device additionally adopting variable-frequency magnetic fields

A technology of laser welding and laser welding head, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of welding seam thermal cracks, large temperature gradient, fast cooling speed, etc., to achieve grain refinement, accelerated Escaping of air bubbles and improving welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

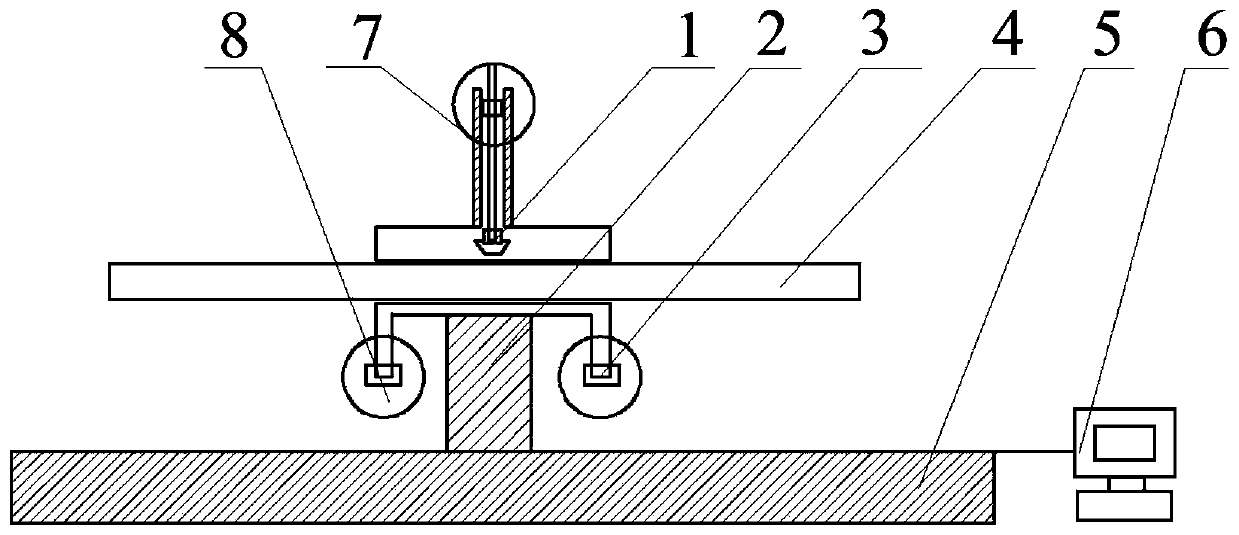

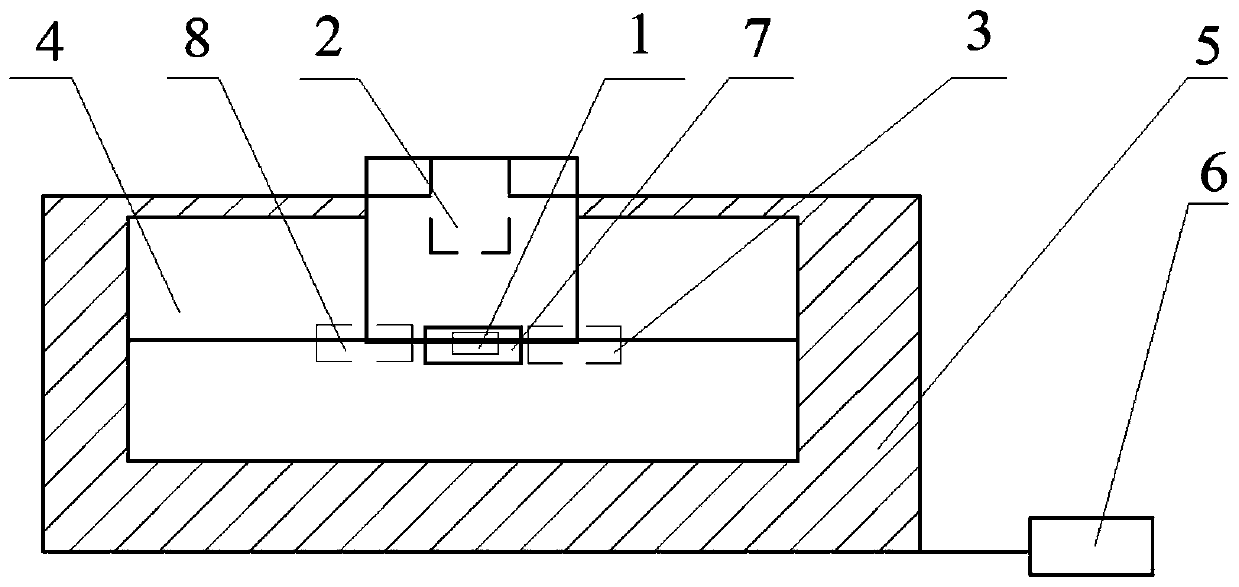

Method used

Image

Examples

Embodiment 1

[0026] The thickness of the welded plate used in this embodiment is 4mm, and the material is 316L stainless steel

[0027] Fix the workpiece on a workbench with a fixture, and use the above-mentioned laser welding process on the thin plate without any auxiliary equipment. The parameters of the laser welding are that the spot diameter is 0.3mm, the laser power is 4kW, and the welding speed is 2m. / min, laser control current 80A, pulse width 15ns, pulse frequency 6Hz. The tensile test and the metallographic observation of the welded seam section were carried out on the welded thin plate, and the tensile data and the welded seam section metallographic diagram were used as comparison group 1.

Embodiment 2

[0029] The strip welding thickness used in this embodiment is 4mm, the material is 316L stainless steel, and the melting point is 1400°C, that is, 1673.15K, T DRX =aT m (K)=0.4×1673.15K=339.26K, that is, 396.11°C. The temperature of the high pressure fluid flow is 50%T DRX =138.64°C. The current passed into the exciting coil is 13A, and the effective magnetic path length is L e is 50mm.

[0030] Technical scheme of the present invention, its concrete steps are:

[0031] (1) Treat the surface of the weldment to be welded and place it on the weldment workbench.

[0032] (2) A direct current of 13A is passed into the exciting coil, and the lower exciting coil 1, the lower exciting coil 2, and the upper exciting coil generate magnetic fields respectively, and the coil numbers of the lower exciting coil 1, the lower exciting coil 2, and the upper exciting coil are respectively 80, 80, 100; the frequency of the magnetic field excited by the lower exciting coil 1, the lower exc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com