Industrial robot uncertainty compensation method

An industrial robot, uncertainty technology, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of inability to achieve high-precision control, reduced operation accuracy, poor control effect, etc., to improve position control performance and reduce defects. Affect and reduce the effect of design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

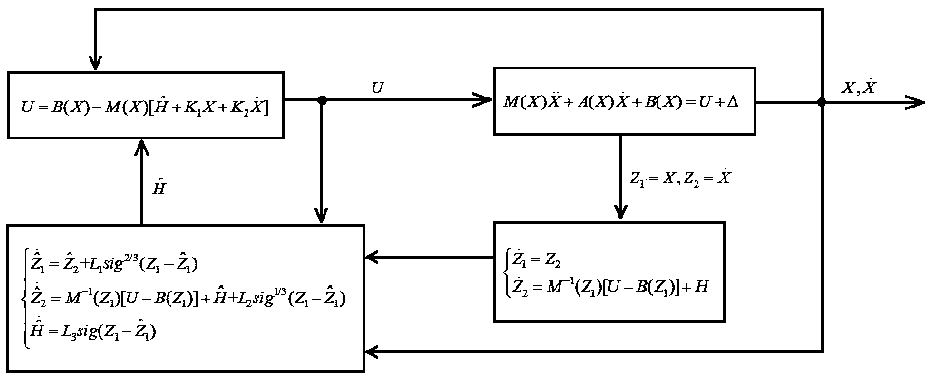

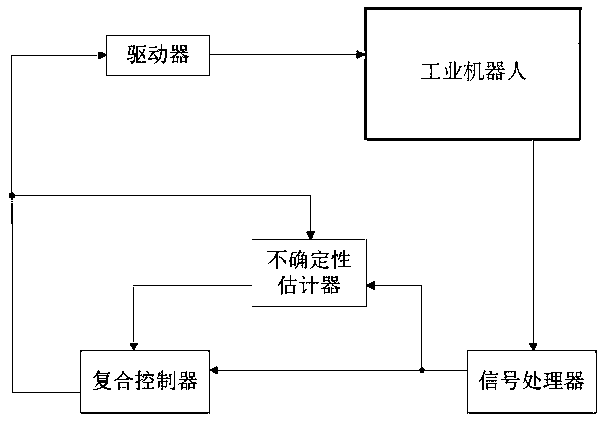

[0026] combine figure 2 , image 3 The method for compensating the uncertainty of industrial robots provided by the present invention comprises the following steps:

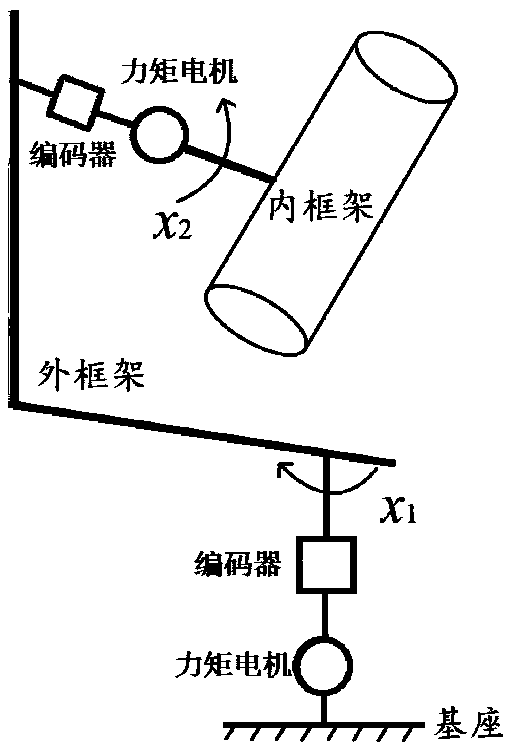

[0027] Step 1, by installing an encoder on each joint of the two-axis industrial robot, obtain the angle information and angular velocity information of each joint, and transmit it to the industrial robot controller in real time;

[0028] Such as figure 2 As shown, an encoder and a torque motor are installed between the base and the outer frame as well as the inner and outer frames. The torque motor provides the frame rotation torque, and the encoder obtains the angle and angular velocity information of the join...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com