Graphene-based wallpaper

An alkenyl-based wallpaper and graphene technology is applied in the field of wallpaper to achieve the effects of avoiding local high temperature, preventing current from escaping, and improving the safety of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

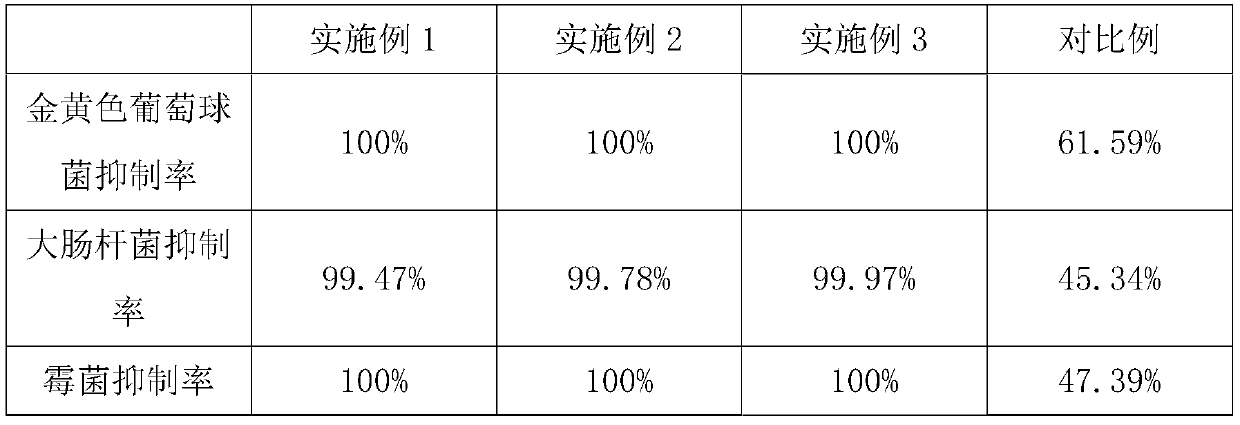

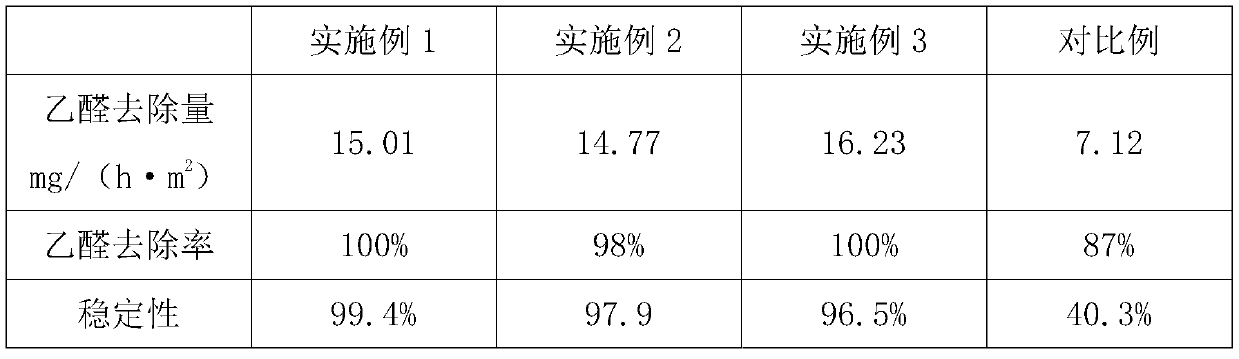

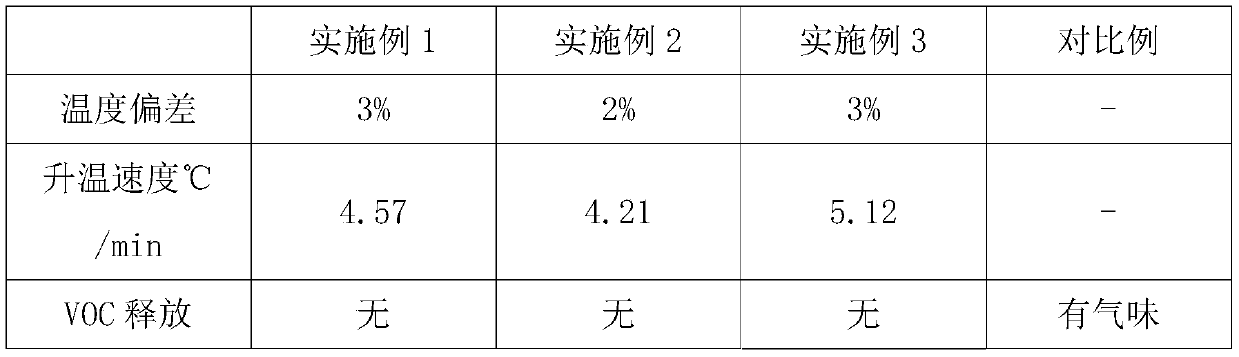

Examples

Embodiment 1

[0035] A graphene-based wallpaper, comprising a graphene resistance layer and a thermally conductive purification layer,

[0036] The formula of described graphene resistance layer is as follows:

[0037] 30 parts of graphene, 10 parts of PVC material, 5 parts of ethyl cellulose, 30 parts of absolute ethanol;

[0038] The formula of the heat conduction purification layer is as follows:

[0039] 10 parts of tourmaline powder, 20 parts of thermal silica gel, 10 parts of nano-alumina, 5 parts of methyl cellulose, 20 parts of distilled water.

[0040] The preparation method of described graphene resistance layer is as follows:

[0041] Step 1, adding ethyl cellulose to absolute ethanol and ultrasonically reacting for 20 minutes to obtain a dispersed ethanol liquid;

[0042] Step 2, adding graphene and PVC to the dispersed ethanol solution for 20 minutes of ultrasonication and microwave reaction for 2 hours to obtain a suspension;

[0043] Step 3, spray the suspension evenly on...

Embodiment 2

[0056] A graphene-based wallpaper, comprising a graphene resistance layer and a thermally conductive purification layer,

[0057] The formula of described graphene resistance layer is as follows:

[0058] 50 parts of graphene, 15 parts of PVC material, 8 parts of ethyl cellulose, 50 parts of absolute ethanol;

[0059] The formula of the heat conduction purification layer is as follows:

[0060] 20 parts of tourmaline powder, 30 parts of thermal silica gel, 15 parts of nano-alumina, 8 parts of methyl cellulose, 40 parts of distilled water.

[0061] The preparation method of described graphene resistance layer is as follows:

[0062] Step 1, adding ethyl cellulose to absolute ethanol and ultrasonically reacting for 50 minutes to obtain a dispersed ethanol liquid;

[0063] Step 2, adding graphene and PVC to the dispersed ethanol solution for 50 minutes of ultrasonication and microwave reaction for 4 hours to obtain a suspension;

[0064] Step 3: Spray the suspension evenly on t...

Embodiment 3

[0077] A graphene-based wallpaper, comprising a graphene resistance layer and a thermally conductive purification layer,

[0078] The formula of described graphene resistance layer is as follows:

[0079] 40 parts of graphene, 13 parts of PVC material, 7 parts of ethyl cellulose, 40 parts of absolute ethanol;

[0080] The formula of the heat conduction purification layer is as follows:

[0081] 15 parts of tourmaline powder, 25 parts of thermal silica gel, 13 parts of nano-alumina, 7 parts of methyl cellulose, 30 parts of distilled water.

[0082] The preparation method of described graphene resistance layer is as follows:

[0083] Step 1, adding ethyl cellulose to absolute ethanol and ultrasonically reacting for 40 minutes to obtain a dispersed ethanol liquid;

[0084] Step 2, adding graphene and PVC to the dispersed ethanol solution for 40 minutes of ultrasonication and microwave reaction for 3 hours to obtain a suspension;

[0085] Step 3: Spray the suspension evenly on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com