Solvent absorption method and device for vinyl chloride rectification tail gas

A technology of vinyl chloride and solvent method, which is applied in the field of vinyl chloride rectification tail gas solvent method absorption, which can solve the problems of production shutdown, production load reduction, vinyl chloride rectification tail gas emission and large vinyl chloride monomer, and achieve low cost, The effect of simple process and convenient operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

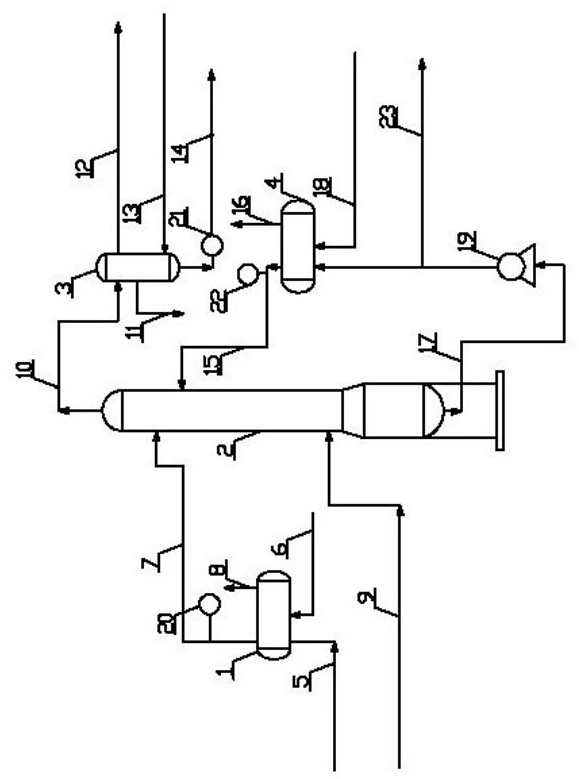

[0014] Embodiment 1: as attached figure 1 As shown, the method for absorbing vinyl chloride rectification tail gas solvent method is carried out according to the following steps: the first step, the absorbent refined ethylene dichloride enters the absorbent cooler 1, utilizes frozen brine to cool the refined dichloroethane, and refines the dichloroethane. Ethyl chloride is cooled to -5°C to -15°C and then enters the absorption tower 2; in the second step, the tail gas from vinyl chloride rectification enters the absorption tower 2, and the refined dichloroethane in the absorption tower 2 continuously absorbs the tail gas from vinyl chloride rectification A part of the refined dichloroethane liquid that has absorbed the tail gas of vinyl chloride rectification is discharged from the bottom of the absorption tower 2 and enters the tower cooler 4, and the refined dichloroethane that has not entered the tower cooler 4 and absorbed the tail gas of vinyl chloride rectification The a...

Embodiment 2

[0016] Example 2: as attached figure 1 As shown, the device for implementing the solvent method absorption method for vinyl chloride rectification tail gas includes an absorbent cooler 1, an absorption tower 2, a tower top condensation cooler 3, a tower kettle cooler 4, and the first inlet at the bottom of the absorbent cooler 1 The absorbent feed pipeline 5 is fixedly connected, the second inlet at the bottom of the absorbent cooler 1 is fixedly connected with the first frozen brine supply pipeline 6, and the first outlet at the top of the absorbent cooler 1 is connected with the first inlet at the upper part of the absorption tower 2 The absorbent discharge pipeline 7 is fixedly connected, the second outlet at the top of the absorbent cooler 1 is fixedly connected with the first frozen brine return water pipeline 8, the middle inlet of the absorption tower 2 is connected with the vinyl chloride rectification tail gas pipeline 9, and the absorption tower 2 A top condensing co...

Embodiment 3

[0017] Embodiment 3: as attached figure 1 As shown, as an optimization of the above embodiment, a feed pump 19 for the tower cooler is fixedly installed on the feed line 17 of the tower cooler.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com