A four-station turntable hot riveting welding machine and its welding method

A four-station turntable and welding machine technology, which is applied to other household appliances, household appliances, household components, etc., can solve the problems of difficult operation efficiency, improper welding head operation, poor professionalism, etc., and achieve high operational stability and accuracy, the device operation threshold is lowered, and the effect of saving time and labor in the welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] For ease of understanding, combined here Figure 1-12 , the concrete structure and working mode of the present invention are further described as follows:

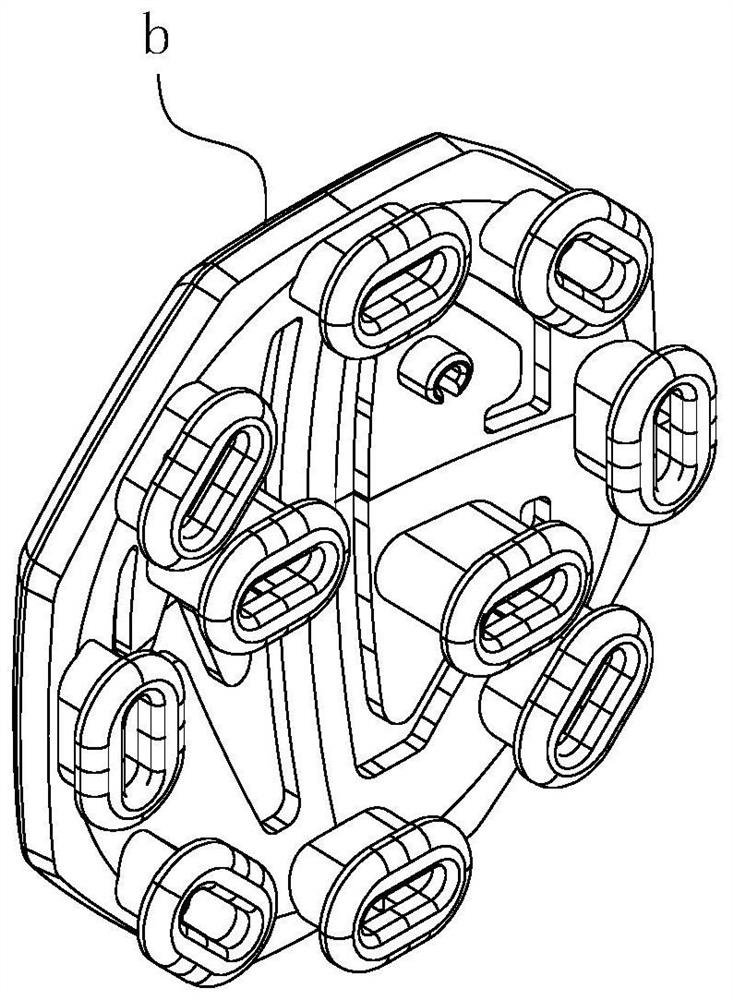

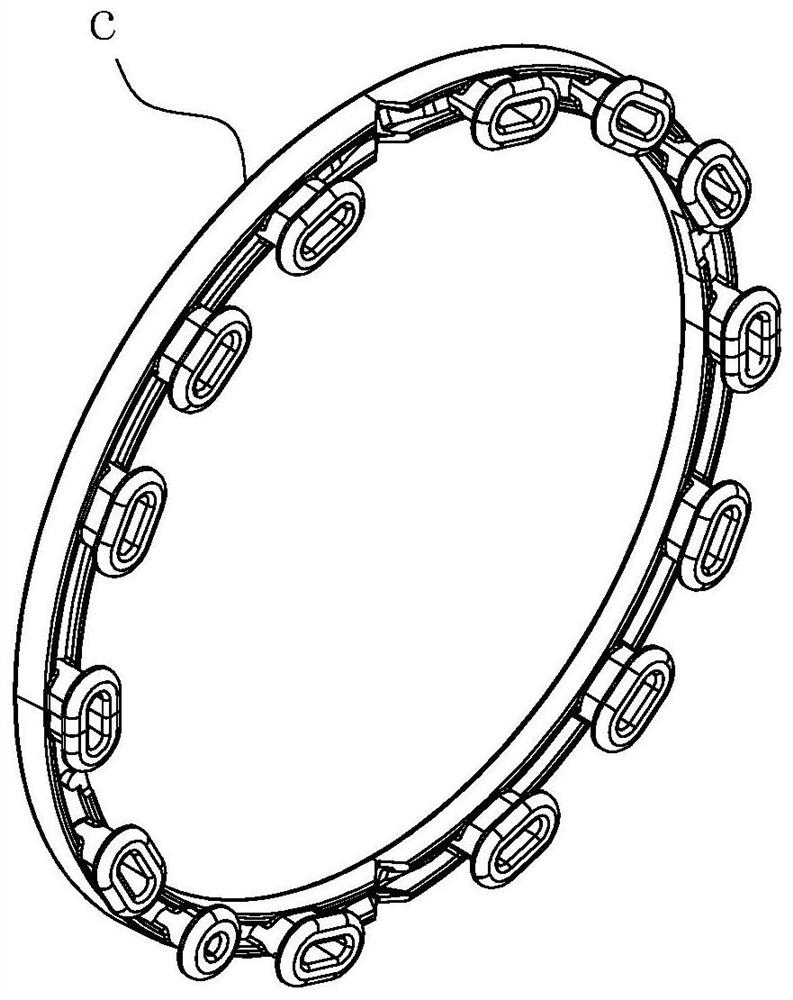

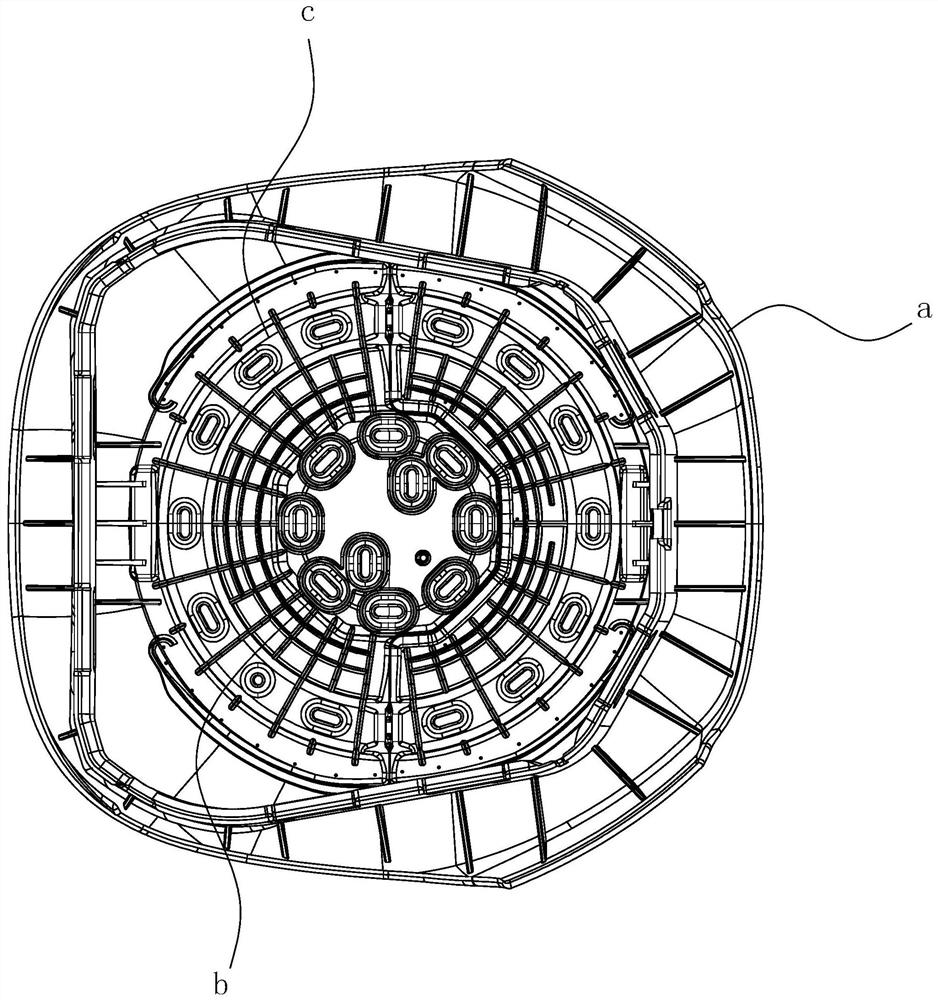

[0067] For ease of understanding the present invention, here at first the structure of department's logo b, department's logo ring c and airbag cover a is described as follows: figure 1 is the three-dimensional structure schematic diagram of division b, and figure 2 It is a schematic diagram of the three-dimensional structure of the logo ring c. In the actual hot riveting installation, it is necessary to figure 1 and figure 2 structured as image 3 are installed into the preset holes in the airbag cover a, and fixed by hot riveting, so that each can form an integrated structure.

[0068] On the basis of above-mentioned existing structure, concrete structure of the present invention is as Figure 4-12 As shown, its main structure includes a frame 10 with a worktable 11, a turntable assembly 20 is arranged a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com