Preparation method of graphene aerogel phase change energy storage material

A phase change energy storage material and graphene aerogel technology, which are applied in the preparation of graphene aerogel phase change energy storage materials and the preparation of new graphene aerogel phase change energy storage materials, and can solve the problem of matrix materials. effects, matrix leakage, degradation of thermophysical properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Graphene oxide and deionized water are uniformly mixed and stirred according to the mass ratio of 1:1000, then polyethylene glycol with a mass ratio of 10:1 to graphene oxide is added, stirred for 1 min, and poured into polytetrafluoroethylene hydrothermal The reaction kettle was kept at 90°C for 20 hours, and the samples were taken out and replaced with deionized water for 3 times, standing for 24 hours each time, then frozen at -20°C for 5 hours, and dried under vacuum for 12 hours to obtain The final graphene airgel polyethylene glycol phase change energy storage material. Sample picture as figure 1 As shown, it can be seen from the figure that the surface of the sample is relatively smooth, the overall color is black of graphene airgel, and the white polyethylene glycol phase change material is well filled in the porous skeleton of graphene airgel ; The density of the sample is 0.16g / cm 3 , The melting enthalpy is 127.6J / g.

example 2

[0028] Graphene oxide and ethanol are uniformly mixed and stirred according to a mass ratio of 20:1000, then stearic acid with a mass ratio of 100:1 to graphene oxide is added, stirred for 10 min, and poured into a polytetrafluoroethylene hydrothermal reaction kettle, Insulate at 240°C for 5 hours, take out the sample and replace it with deionized water 9 times, let it stand for 8 hours each time, freeze at -80°C for 48 hours, and vacuumize and dry for 36 hours to obtain the final graphene airgel Stearic acid phase change energy storage material. The density of this sample is 0.36g / cm 3 , The enthalpy of fusion is 346.7J / g.

example 3

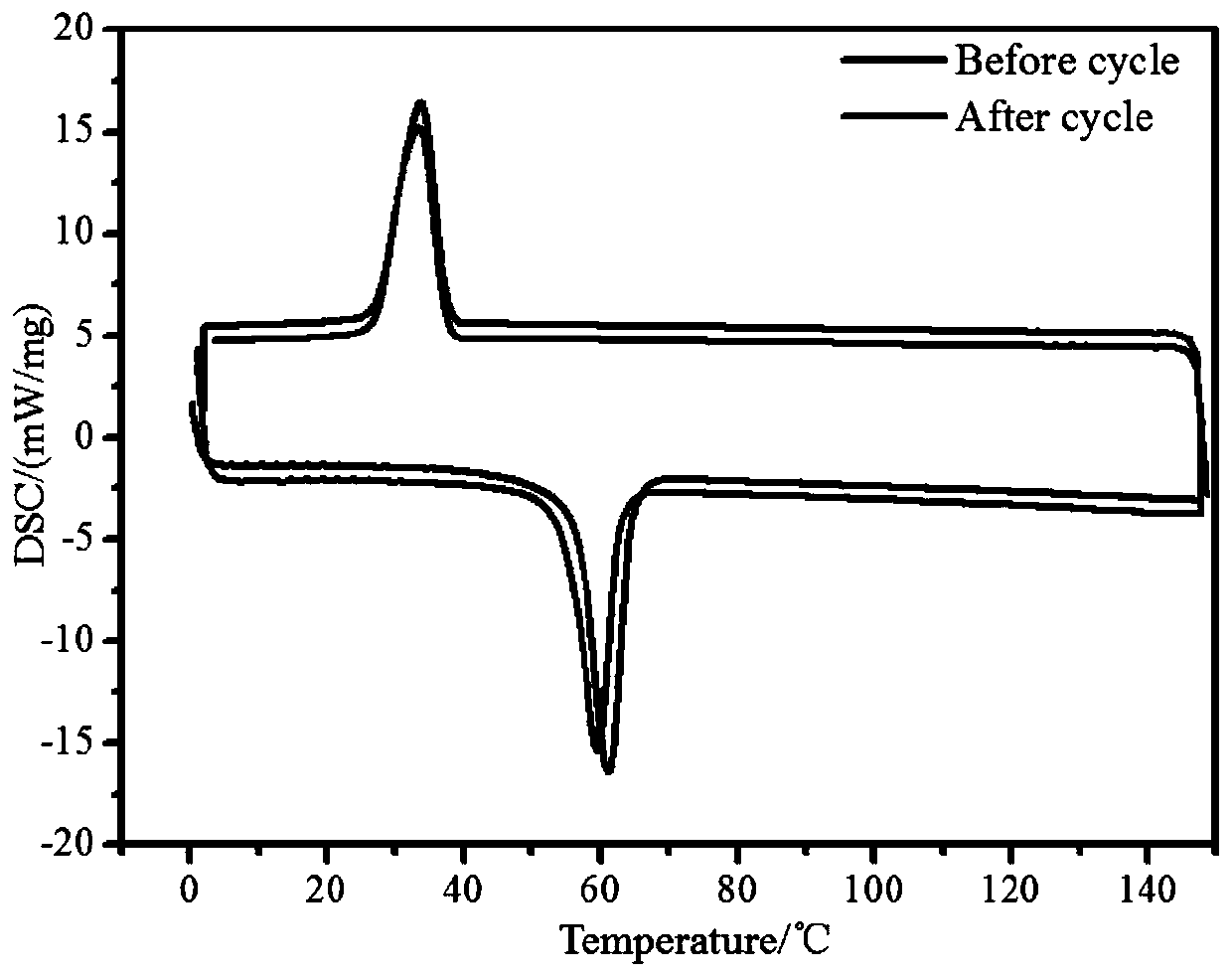

[0030] Graphene oxide and acetone are uniformly mixed and stirred according to the mass ratio of 16:1000, then add paraffin wax with a mass ratio of 50:1 to graphene oxide, stir for 10 min, pour into a polytetrafluoroethylene hydrothermal reaction kettle, and heat at 240 The temperature was kept at ℃ for 9 hours, and the samples were taken out and replaced with ethanol 9 times, each time standing for 8 hours. Then put it in a CO2 supercritical reactor, and dry it for 8 hours in a high-pressure reactor with a reaction temperature of 70 °C, a pressure of 8 MPa, and a gas release rate of 5 L / min, so as to obtain the final graphene airgel paraffin phase transition energy storage materials. The density of this sample is 0.26g / cm 3 , SEM pictures such as figure 2 As shown, the sheet-like network structure of graphene airgel can be clearly seen from the left figure, and the paraffin phase change material can be well filled in the skeleton of graphene airgel from the right figure; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com