Hydrogen compressing system and hydrogen compression method

A compression system and compression method technology, applied in container filling method, container discharge method, hydrogen technology, etc., can solve the problems of high storage cost and high compression cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

[0018] A1. System structure:

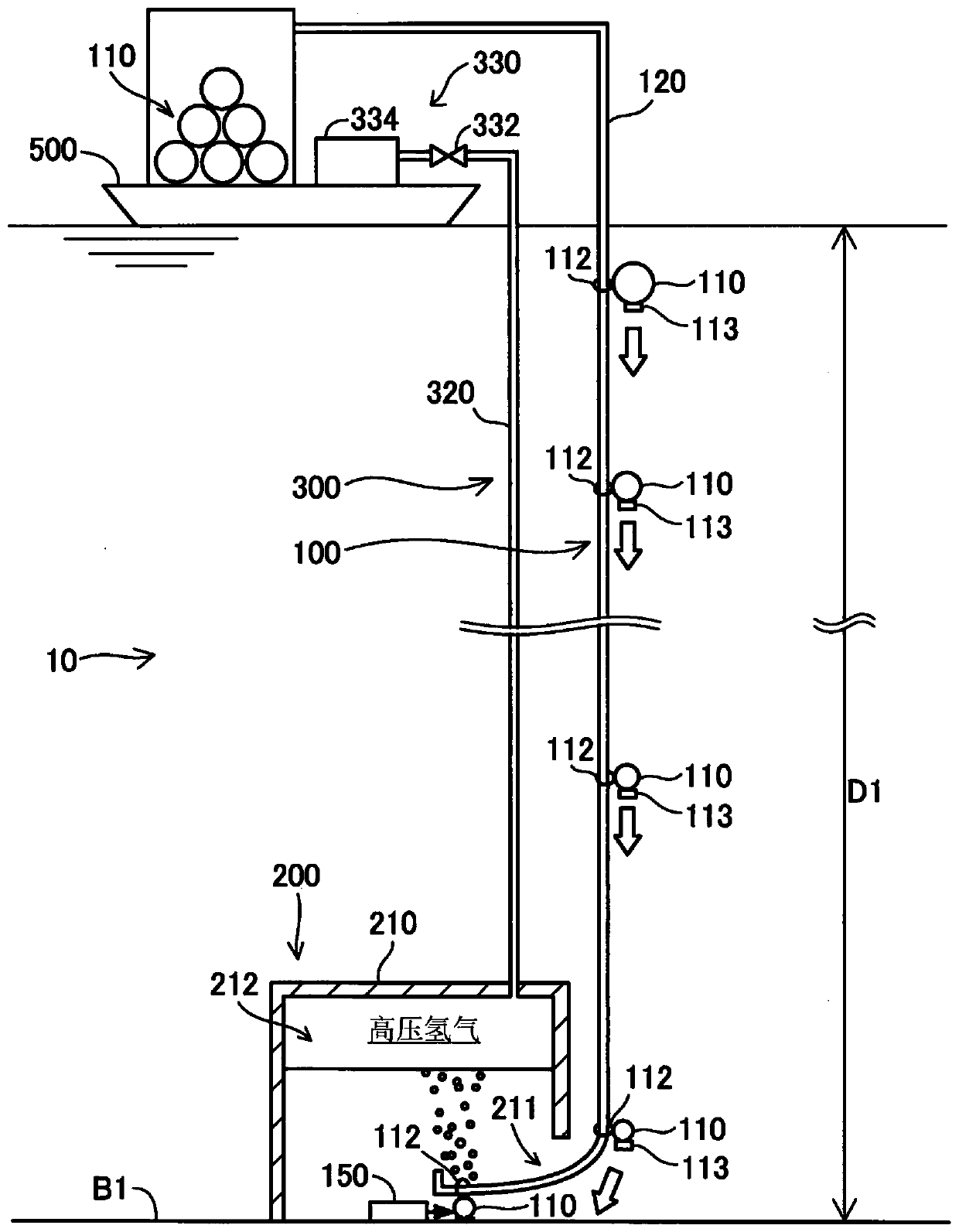

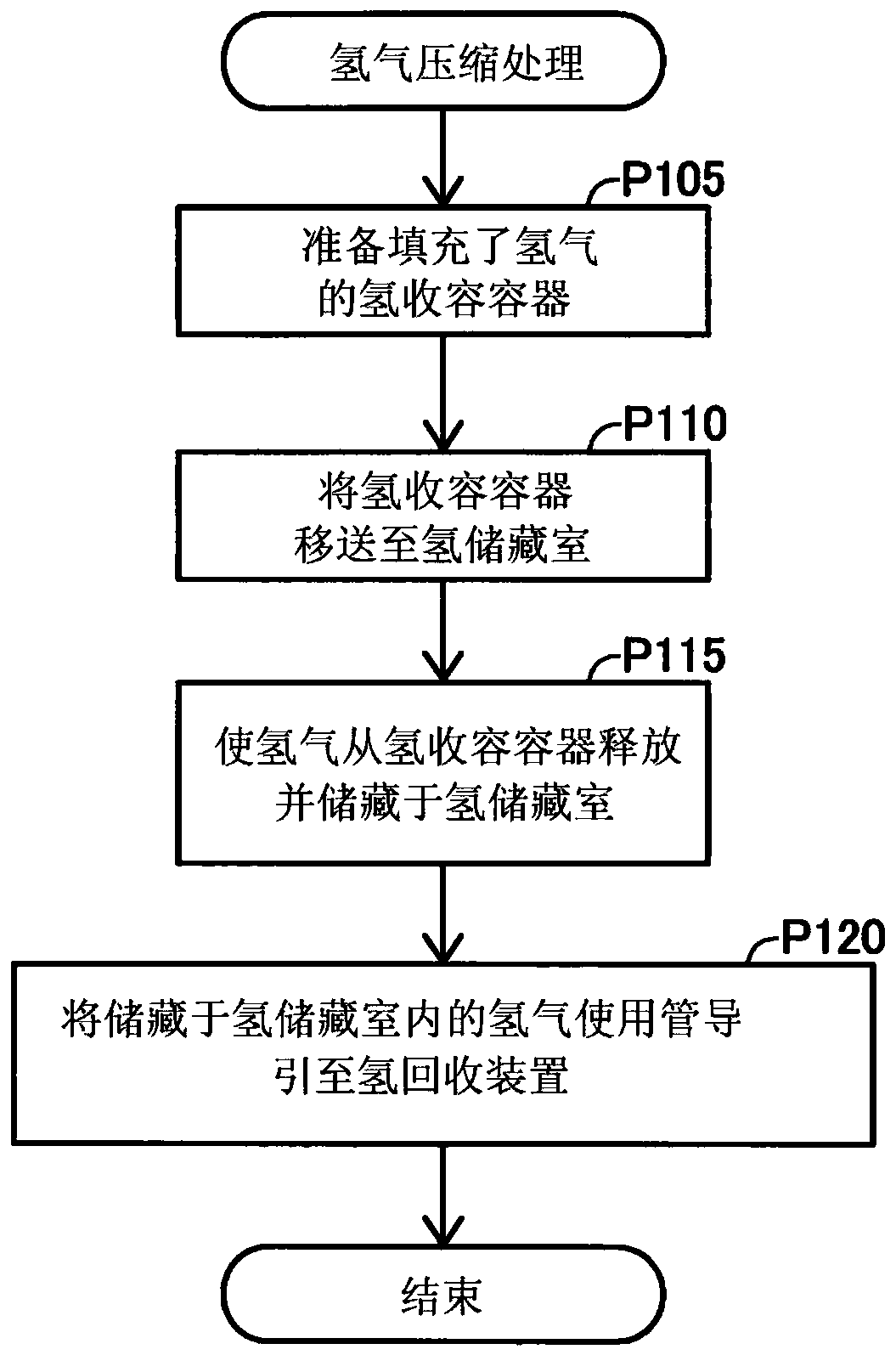

[0019] figure 1 It is an explanatory diagram showing a schematic configuration of a hydrogen compression system 10 as an embodiment of the present invention. The hydrogen gas compression system 10 uses water pressure in the sea to compress hydrogen gas, and stores the compressed hydrogen gas. The hydrogen compression system 10 includes a transfer unit 100 , a gas release unit 150 , a storage unit 200 , and a recovery unit 300 .

[0020] The transfer unit 100 guides the hydrogen storage container 110 filled with hydrogen gas to the hydrogen storage chamber 210 included in the storage unit 200 .

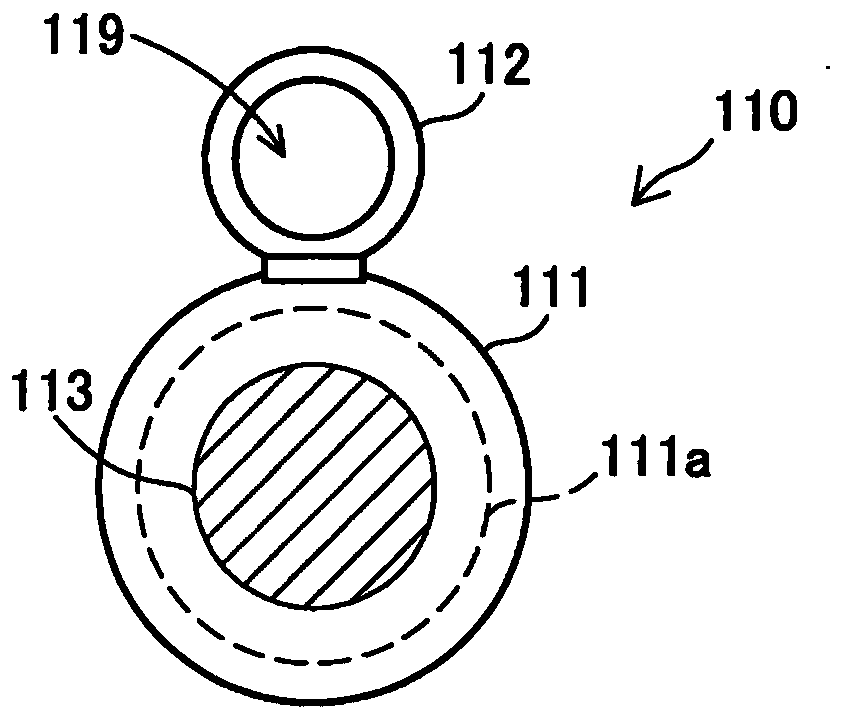

[0021] figure 2 It is an external view showing the structure of the hydrogen storage container 110 . The hydrogen storage container 110 includes a main body portion 111 , an attachment portion 112 , and a weight portion 113 . The main body portion 111 has a substantially spherical appearance shape, and a hydrogen storage portion 111 a is formed insi...

no. 2 Embodiment approach

[0035] Figure 4 It is an explanatory diagram showing a schematic configuration of a hydrogen compression system 10a in the second embodiment. The hydrogen compression system 10a according to the second embodiment has a transfer recovery unit 400 instead of the transfer unit 100 and the recovery unit 300, and figure 1 The hydrogen compression system 10 of the first embodiment shown is different. The other configurations of the hydrogen compression system 10 a of the second embodiment are the same as those of the hydrogen compression system 10 of the first embodiment, and therefore the same components are assigned the same reference numerals and detailed descriptions thereof are omitted.

[0036] The transfer and recovery unit 400 is a functional unit obtained by combining the transfer unit 100 and the recovery unit 300 in the first embodiment. That is, the transfer recovery unit 400 guides the hydrogen storage container 110 filled with hydrogen gas to the hydrogen storage ch...

Embodiment approach 1

[0042] In each embodiment, the main body 111 of the hydrogen storage container 110 is formed of aluminum, but it is not limited to aluminum, and may be formed of other arbitrary types of metals. In addition, the main body portion 111 may be formed of resin for the purpose of improving corrosion resistance. In this structure, by forming the main body 111 to have a structure that deforms under a water pressure environment lower than about 70.9 MPa and does not crack even under this water pressure environment, The same effects as those of the respective embodiments are achieved. As the main body portion 111 of such a hydrogen storage container 110 , for example, a resin liner used in a hydrogen storage fuel tank may be used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com