Method for quantitatively judging thermal cracking degree of crude oil and application of method

A technology for thermal cracking and crude oil, which is applied in the field of petroleum exploration and development, and can solve the problems of inaccurate indication of geochemical characteristics, difficulties in adamantane lines, and complex quantitative methods for adamantane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

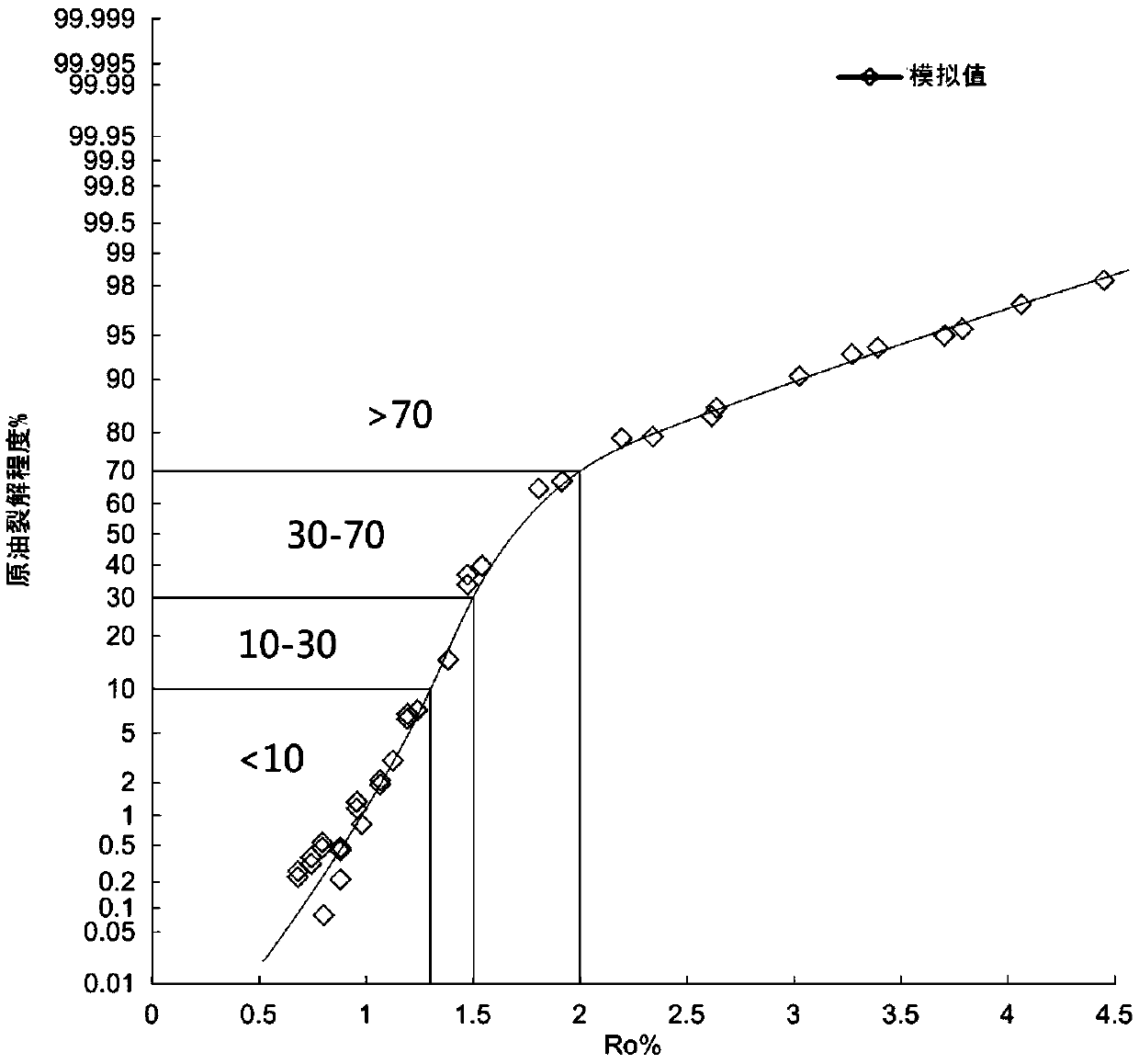

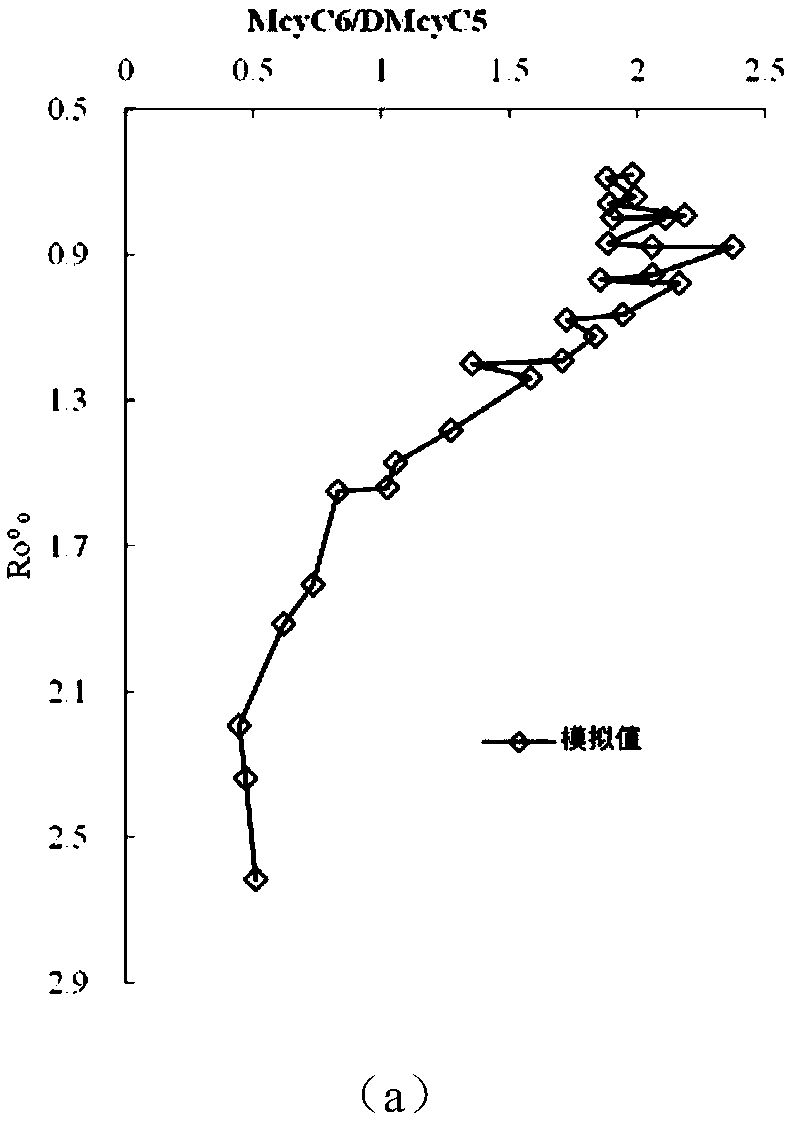

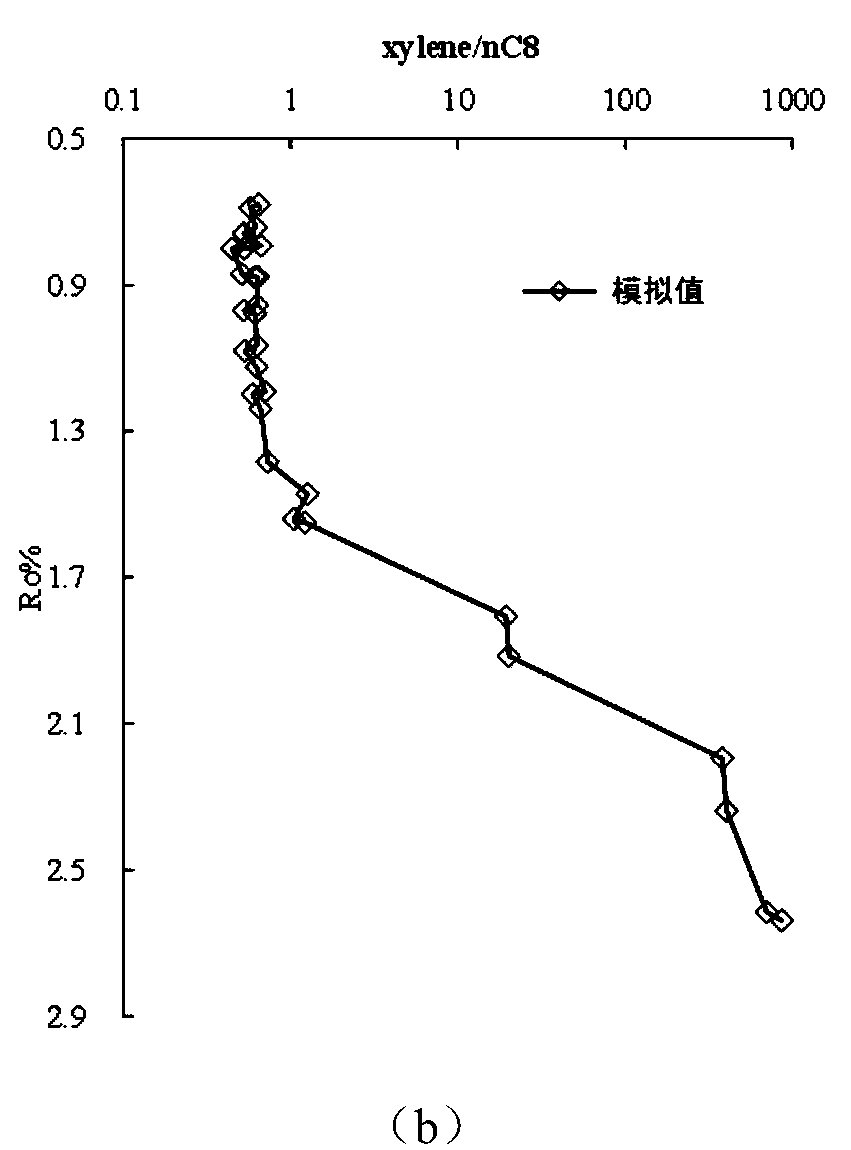

[0056] The establishment of the relationship formula for determining the degree of cracking of crude oil:

[0057] The typical crude oil in the Tarim Basin with low maturity (Ro value between 0.8-1.0%) was collected to carry out the gold tube thermal simulation experiment.

[0058] The conditions of the gold tube thermal simulation experiment are:

[0059] Under constant pressure (the actual formation pressure of the simulated crude oil sample is set to 75MPa), with temperature as the main influencing factor, the experimental temperature rise adopts a constant temperature single-point mode, that is, each temperature point corresponds to a crude oil sample, and two different temperature rise curves are set up. The heating rates are 20°C / h and 2°C / h respectively, and the test point temperature is set between 336-600°C, with a temperature point every 24°C, a total of 12 temperature points.

[0060] In the gold tube thermal simulation experiment, two parallel experiments were car...

Embodiment 2

[0075] Judgment of thermal cracking degree of crude oil in Tahe area:

[0076] Collect the crude oil of Tahe area and carry out light hydrocarbon fingerprint chromatography-mass spectrometry analysis, obtain the MCyC6 / DMCyC5 of the crude oil of Tahe area to be 1.93-3.06, xylene / nC8 is 0.25-0.63, thus, judge the thermal cracking degree of crude oil obtained in embodiment 1 According to the knowledge relational formula, it can be judged that the crude oil in the Tahe area has not undergone obvious thermal cracking, and the degree of thermal cracking is less than 10%. This result is consistent with the previous geological understanding and coincides with the corresponding geological background.

Embodiment 3

[0078] Judgment of thermal cracking degree of crude oil in Yuejin area:

[0079] The crude oil in Yuejin area is collected for light hydrocarbon fingerprint chromatography-mass spectrometry analysis, and the MCyC6 / DMCyC5 of crude oil in Yuejin area is 2.05-2.65, and the xylene / nC8 is 0.34-0.65. Therefore, the identification relationship of thermal cracking degree of crude oil obtained in Example 1 According to the formula, it can be judged that the crude oil in the Yuejin area has not experienced obvious thermal cracking, and the degree of thermal cracking is less than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com