(METH)acrylic resin and method for controlling strain thereof

A technology of acrylic and acrylic monomers, which is applied in the field of improved manufacturing of resin (acrylic resin), which can solve problems such as insulation breakdown and large displacement, and achieve the effect of high scalability and low strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

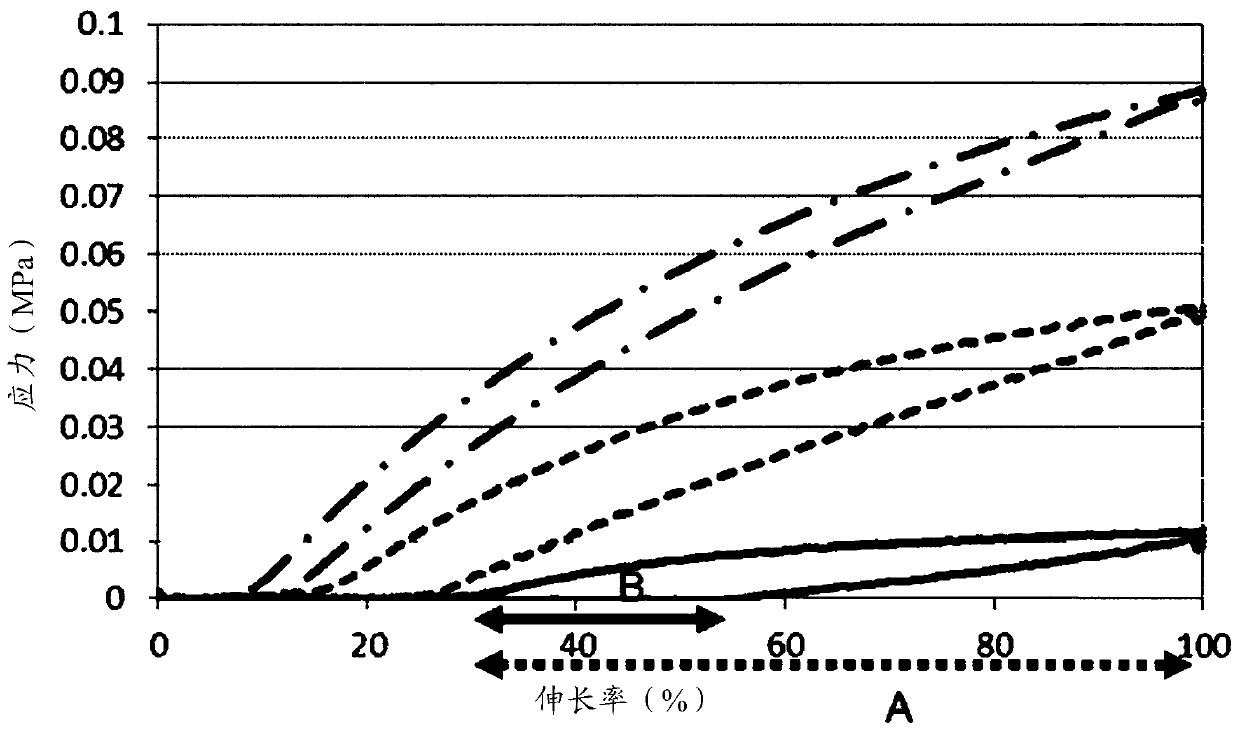

[0664] (Example 1: Measurement of the illuminance of ultraviolet rays that generate a predetermined strain)

[0665] The illuminance of ultraviolet light for producing a polymer having a predetermined strain is determined by the following procedure.

[0666] [Derivation of strain-illuminance relationship]

[0667] 1) Provide the starting material monomer

[0668] For each specific example after Example 2, an appropriate monomer is selected. For example, in the case of the (meth)acrylic polymer of Example 2, by mixing 7.03 g of ethyl acrylate, 0.17 g of diethylene glycol dimethacrylate, and 2,4,6-trimethacrylate as a polymerization initiator, Toluyldiphenylphosphine oxide [manufactured by BASF Corporation, trade name: Irgacure TPO] 0.0042 g was provided as a monomer component containing a polymerization initiator.

[0669] 2) The starting material monomer is irradiated with ultraviolet rays of a specific intensity to polymerize

[0670] After obtaining an appropriate monome...

Embodiment 2

[0693] Acrylic Resin(1)

[0694] By mixing 7.03 g of ethyl acrylate, 0.17 g of diethylene glycol dimethacrylate, and 2,4,6-trimethylbenzoyldiphenylphosphine oxide [manufactured by BASF Corporation, trade name: Irgacure TPO] 0.0042 g to obtain a monomer component containing a polymerization initiator.

[0695] The monomer component obtained above is poured into a transparent glass mold with a release film (length: 100mm, width: 100mm, depth: 0.3mm) so that the amount of radiation is 0.5 to 50mW / cm 2 The monomer component was irradiated with ultraviolet rays in a manner to polymerize the monomer component in bulk, thereby obtaining a (meth)acrylic elastomer. The measurement results are shown in Table 1 below.

Embodiment 3

[0697] Acrylic Resin(2)

[0698] By mixing 30.01 g of ethyl acrylate, 0.35 g of 2-hydroxyethyl acrylate, and 2,4,6-trimethylbenzoyldiphenylphosphine oxide [manufactured by BASF, trade name: Irgacure TPO] as a polymerization initiator 0.038 g to obtain a monomer component containing a polymerization initiator.

[0699] The monomer component obtained above is poured into a transparent glass mold with a mold release film (length: 100mm, width: 100mm, depth: 2mm) so that the irradiation dose becomes 0.5 to 50mW / cm 2 The monomer component was irradiated with ultraviolet rays in a manner to polymerize the monomer component in bulk, thereby obtaining a (meth)acrylic elastomer. The measurement results are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com