Simulated moving bed device and method for separating multi-component dihydric alcohol

A simulated moving bed, multi-component technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the problems of single structure, non-continuous operation, low separation efficiency, etc., and achieve the goal of improving separation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

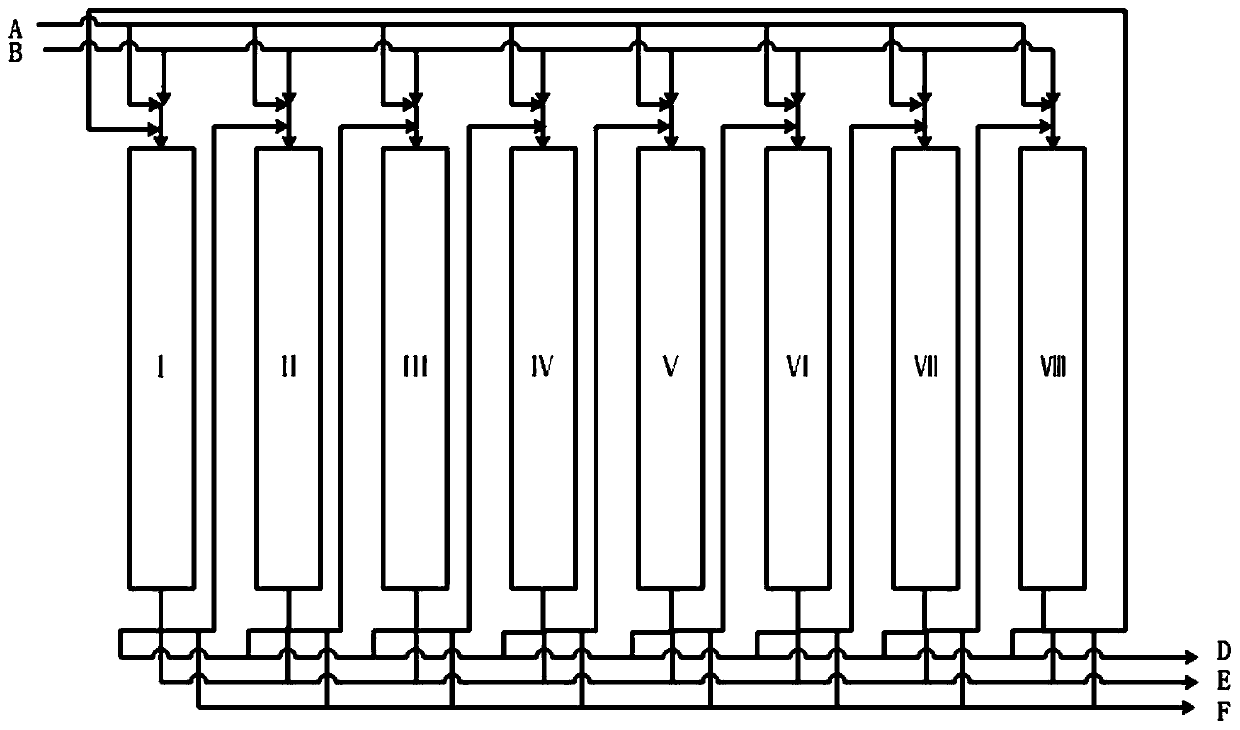

[0050] This embodiment provides a simulated moving bed device, its structure is as follows figure 1 As shown, there are 8 chromatographic columns (respectively I column, II column, III column, IV column, V column, VI column, VII column, VIII column) with built-in adsorbent NaY molecular sieve, and each chromatographic column is connected to There is a back pressure valve for adjusting the operating pressure in the chromatography column, and each chromatography column has 2 feed channels (respectively A channel, B channel) and 3 output channels (respectively D channel, E channel, F channel channel), and the chromatographic columns are connected in series with each other through connecting channels;

[0051] Valves for controlling the opening and closing of the channels are arranged on the feed channel and the output channel of each chromatographic column, and on the connection channels between adjacent chromatographic columns.

[0052] This embodiment also provides a method fo...

Embodiment 2

[0062] This embodiment provides a simulated moving bed device, the difference from Embodiment 1 is that the built-in adsorbent is Mitsubishi Chemical Holdings Co., Ltd. SP70 resin.

[0063] This embodiment also provides a method for separating multi-component dihydric alcohols. The difference from Embodiment 1 is that the simulated moving bed device provided by this embodiment is used for separation, the operating pressure is normal pressure, and the operating temperature is normal temperature. Agent is deionized water; t=305min, n=8;

[0064] Starting from the introduction of the desorbent, the extract from 0-60 minutes is a mixture of 1,2-butanediol and desorbent (1,2-butanediol mass fraction 68.98%), and after the desorbent is evaporated, the obtained The purity of 1,2-butanediol is 98.79%; the extraction liquid at 60-150 minutes is a mixture of ethylene glycol, 1,2-butanediol and analytic agent; the extraction liquid at 150-300 minutes is a mixture of ethylene glycol and ...

Embodiment 3

[0066] This embodiment provides a simulated moving bed device, which is different from Embodiment 2 in that the built-in adsorbent is DA201-A resin from Jiangsu Suqing Water Treatment Engineering Group Co., Ltd.

[0067] This embodiment also provides a method for separating multi-component diols. The difference from Example 2 is that the simulated moving bed device provided in this embodiment is used for separation. The multi-component diols are separated from 1,2-propanediol 50wt% and 50wt% of 2,3-butanediol, and ethanol as the analytical agent; t=265min, n=8;

[0068]Starting from the introduction of the desorbent, the extract from 0-70 minutes is a mixture of 2,3-butanediol and desorbent (2,3-butanediol mass fraction 60.89%), and after the desorbent is evaporated, the obtained The purity of 2,3-butanediol is 98.45%; the extract from the 70-175min is a mixture of 1,2-propanediol, 2,3-butanediol and the resolving agent; the extract from the 175-260min is 1, The mixed solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com