Purification method and purification device of nanocrystalline cellulose

A technology of nano-microcrystals and purification methods, applied in chemical instruments and methods, fiber raw material treatment, reverse osmosis, etc., can solve the problems of difficult control of derivation process, difficult dispersion, easy agglomeration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

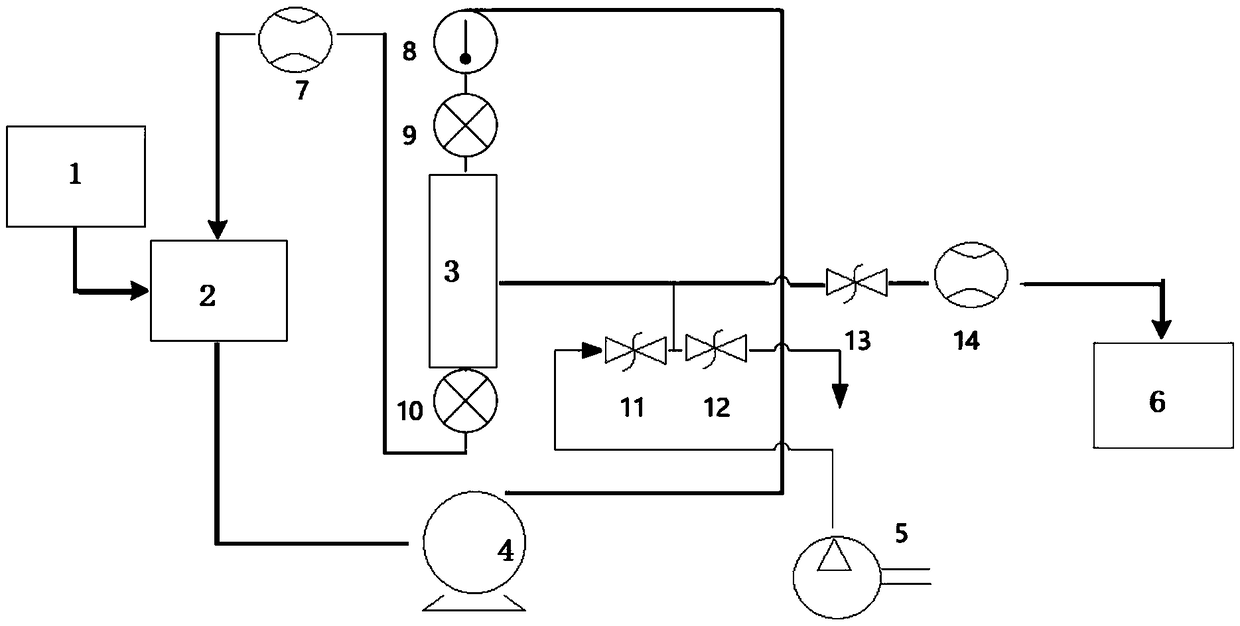

[0040] Such as figure 1 Shown, the present invention provides a kind of purifying device that realizes purifying method of the present invention, comprises water source 1, dispersion liquid collector 2 (or claims processing tank), ceramic nanofiltration membrane post 3, pump 4, compressed air source 5 ( Such as air compressor), eluate collection tank 6;

[0041] The dispersion collector 2 is connected to the front end of the ceramic membrane nanofiltration column 3 by a pump 4;

[0042] The water source 1 is connected to the dispersion collector 2;

[0043] The horizontal outlet of the ceramic nanofiltration membrane column 3 is connected with the compressed air source 5 and the eluate collection tank 6 respectively through pipelines, wherein through valves (such as the first electromagnetic valve (or claiming air intake valve 11) and the second electromagnetic valve (or claim emptying valve 12) to control the entry and discharge of compressed air, and control the effluent t...

Embodiment 2

[0051] The method for purifying nano-microcrystalline cellulose using the purification device described in Example 1 may further comprise the steps:

[0052] 1) Add the dispersion (pH2 ;The post-column pressure is 1.0~1.2kg / cm 2Add pure water intermittently to the treatment tank, the dispersion liquid flowing through the ceramic nanofiltration membrane column flows back to the treatment tank, and the eluate is collected in the eluate collection tank; the ceramic nanofiltration membrane column is a tubular ceramic Membrane; the tube wall of the tubular ceramic membrane is densely covered with micropores;

[0053] 2) When the second flow detector detects that the flow rate of the eluate is less than 0.4 L / min, close the third solenoid valve, open the first solenoid valve, and pour compressed air into the column for 3 seconds. The pressure of the compressed air is 0.1 L / min. ~1KPa, close the first solenoid valve; open the second solenoid valve, and last for 4s, discharge the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com