Titanium-based amorphous state brazing filler metal with low welding temperature and preparing method of titanium-based amorphous state brazing filler metal

A welding temperature, amorphous technology, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of difficult preparation of amorphous solder and lower melting point of titanium alloy amorphous solder, etc. To achieve the effect of good promotion and practical value, good economic benefits and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0028] The brazing material composition with low soldering temperature in this embodiment is composed of Ti, Zr, V, Cu, Be elements. The mass percent of each chemical composition of the solder is specifically Zr content of 25%, Cu content of 10%, V content of 10%, Be content of 15%, and the balance of Ti.

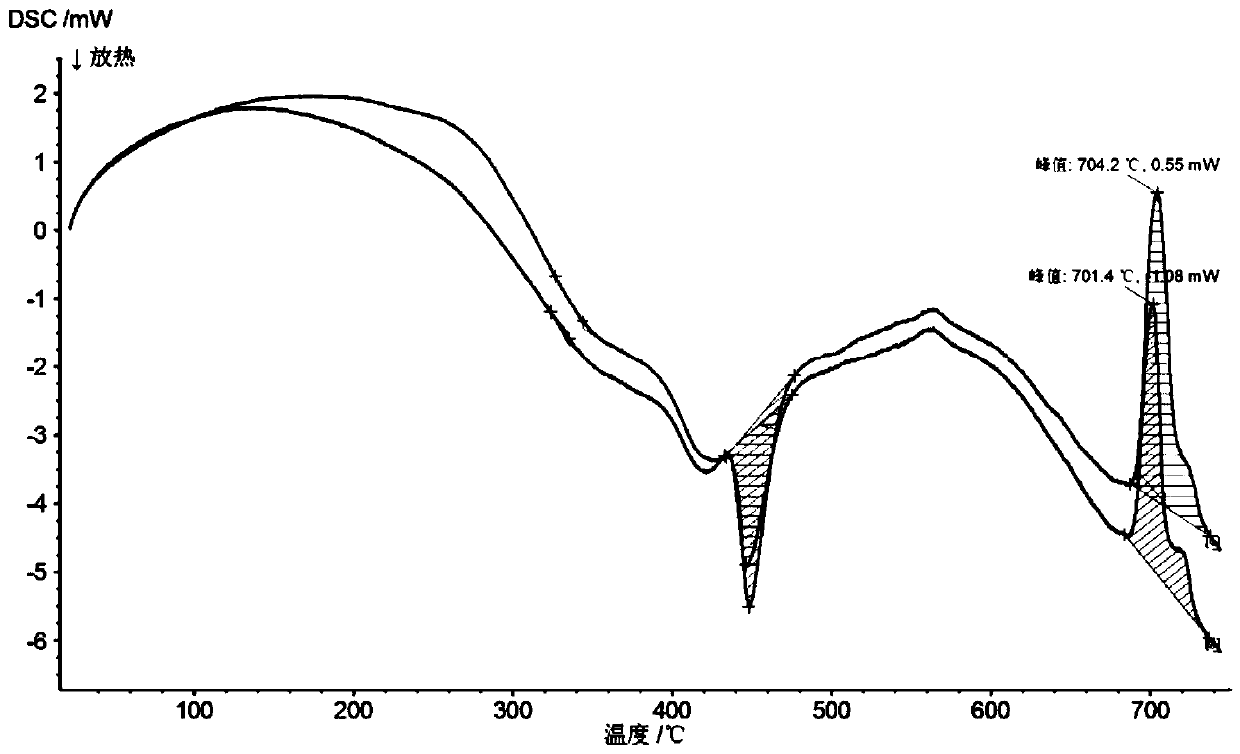

[0029] TiZrVCuBe was pre-alloyed by magnetic levitation melting and casted into a short rod with a diameter of 20 mm. Samples were taken from cast rods and subjected to DSC melting point tests as figure 1 As shown, the solidus temperature of the solder is 680°C, and the liquidus temperature is 740°C.

[0030] Using the vacuum quenching equipment previously applied by the inventor (China Invention Patent Application No. 201810510425.5), a certain amount of TiZrVCuBe alloy is placed in a high-purity quartz tube. The alloy in the quartz tube is heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com