Preparation method of toughened polypropylene resin

A polypropylene resin and polypropylene technology, which is applied in the field of preparation of toughened polypropylene resin, can solve problems such as limited application, and achieve the effects of simple process operation and controllable polymer performance indicators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

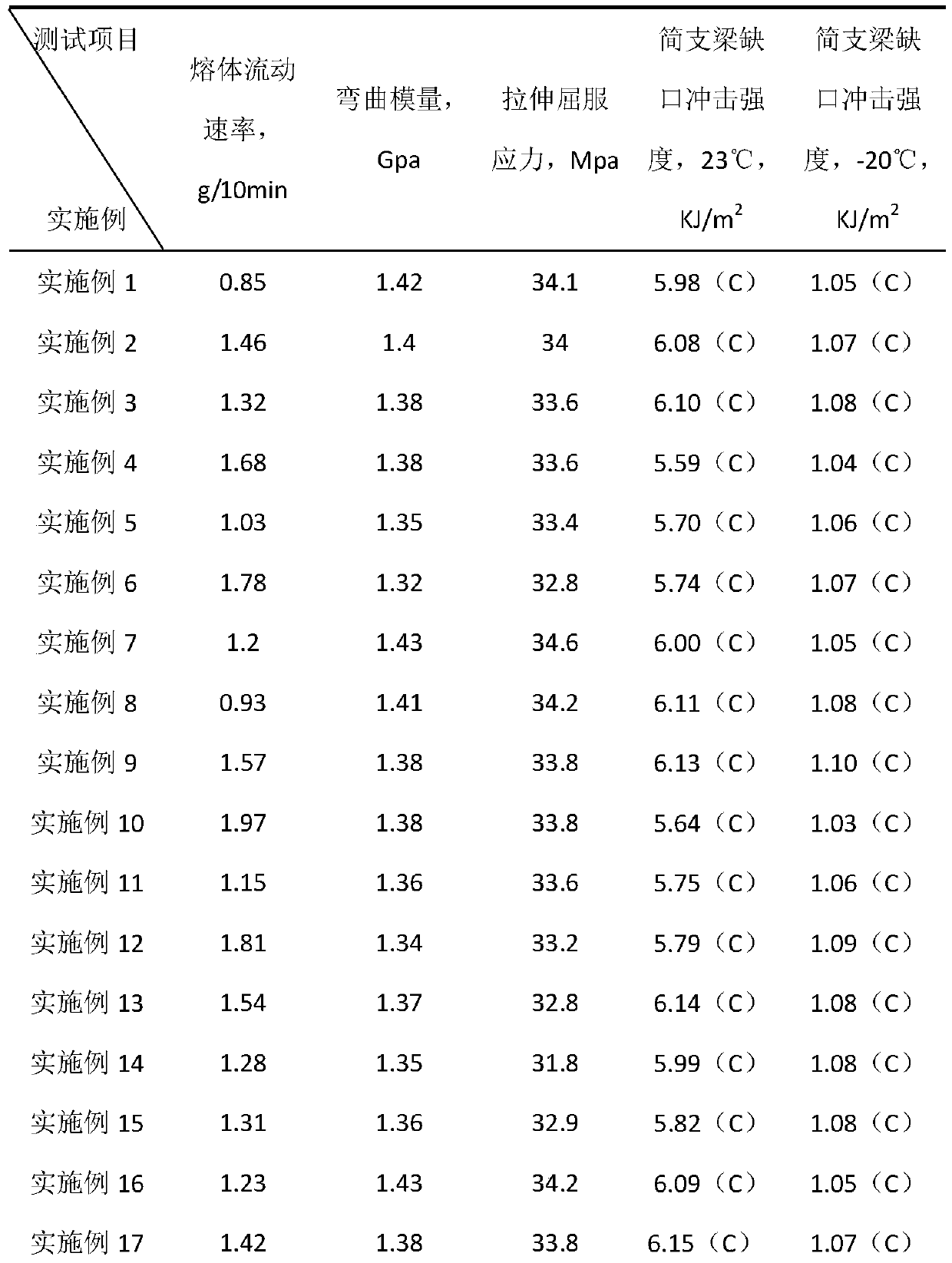

[0025] 1. With liquid propylene of purity 99.6% as main raw material, adopt NDQ catalyst (catalyst activity 19Kg polypropylene / g catalyst), add the ethylene of purity 99.96% of propylene mass percent 0.8%, on Spheripol process single-loop polypropylene device, Produced random copolymerized polypropylene base resin;

[0026] 2. Add 5 parts of melt flow rate of 0.8g / 10min and density of 0.915g / cm to 95 parts of random copolymerized polypropylene extrusion resin 3Ultra-low-density polyethylene resin, and add additives, including 0.05 parts of antioxidant 1010, 0.1 part of antioxidant 168, 0.05 parts of calcium stearate, 0.05 parts of monoglyceride stearate, HPN-20E It is 0.025 parts. After fully mixing, it is extruded through a twin-screw extruder. The temperatures of the extruder from feeding to the head are: 190°C, 192°C, 195°C, 200°C, 205°C, 205°C, 200°C , 195°C, 190°C, 185°C, pelletized to obtain toughened polypropylene resin. The performance test is carried out according t...

Embodiment 2

[0028] 1. With liquid propylene of purity 99.7% as main raw material, adopt NDQ catalyst (catalyst activity 20Kg polypropylene / g catalyst), add the ethylene of purity 99.95% of propylene mass percent 0.8%, on Spheripol process single-loop polypropylene device, Produced random copolymerized polypropylene base resin;

[0029] 2. Add 10 parts of melt flow rate 0.9g / 10min and density 0.913g / cm to 90 parts of random copolymerized polypropylene base resin 3 Ultra-low-density polyethylene resin, and add additives, including 0.05 parts of antioxidant 1010, 0.1 part of antioxidant 168, 0.05 parts of calcium stearate, 0.05 parts of monoglyceride stearate, HPN-20E It is 0.025 parts. After fully mixing, it is extruded through a twin-screw extruder. The temperatures of the extruder from feeding to the head are: 192°C, 192°C, 196°C, 203°C, 206°C, 208°C, 201°C , 195°C, 191°C, 186°C, and granulate to obtain the toughened polypropylene resin of the present invention. The performance test is ...

Embodiment 3

[0031] 1. With liquid propylene of purity 99.8% as main raw material, adopt NDQ catalyst (catalyst activity 21Kg polypropylene / g catalyst), add the ethylene of the purity 99.97% of propylene mass percent 0.8%, on Spheripol process single-loop polypropylene device, Produced random copolymerized polypropylene base resin;

[0032] 2. Add 15 parts of melt flow rate 1.0g / 10min and density 0.914g / cm to 85 parts of random copolymerized polypropylene base resin 3 Ultra-low-density polyethylene resin, and add additives, including 0.05 parts of antioxidant 1010, 0.1 part of antioxidant 168, 0.05 parts of calcium stearate, 0.05 parts of monoglyceride stearate, HPN-20E It is 0.025 parts. After fully mixing, it is extruded through a twin-screw extruder. The temperatures of the extruder from feeding to the head are: 196°C, 197°C, 198°C, 203°C, 209°C, 209°C, 202°C , 198°C, 193°C, 188°C, and granulate to obtain the toughened polypropylene resin of the present invention. The performance test...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

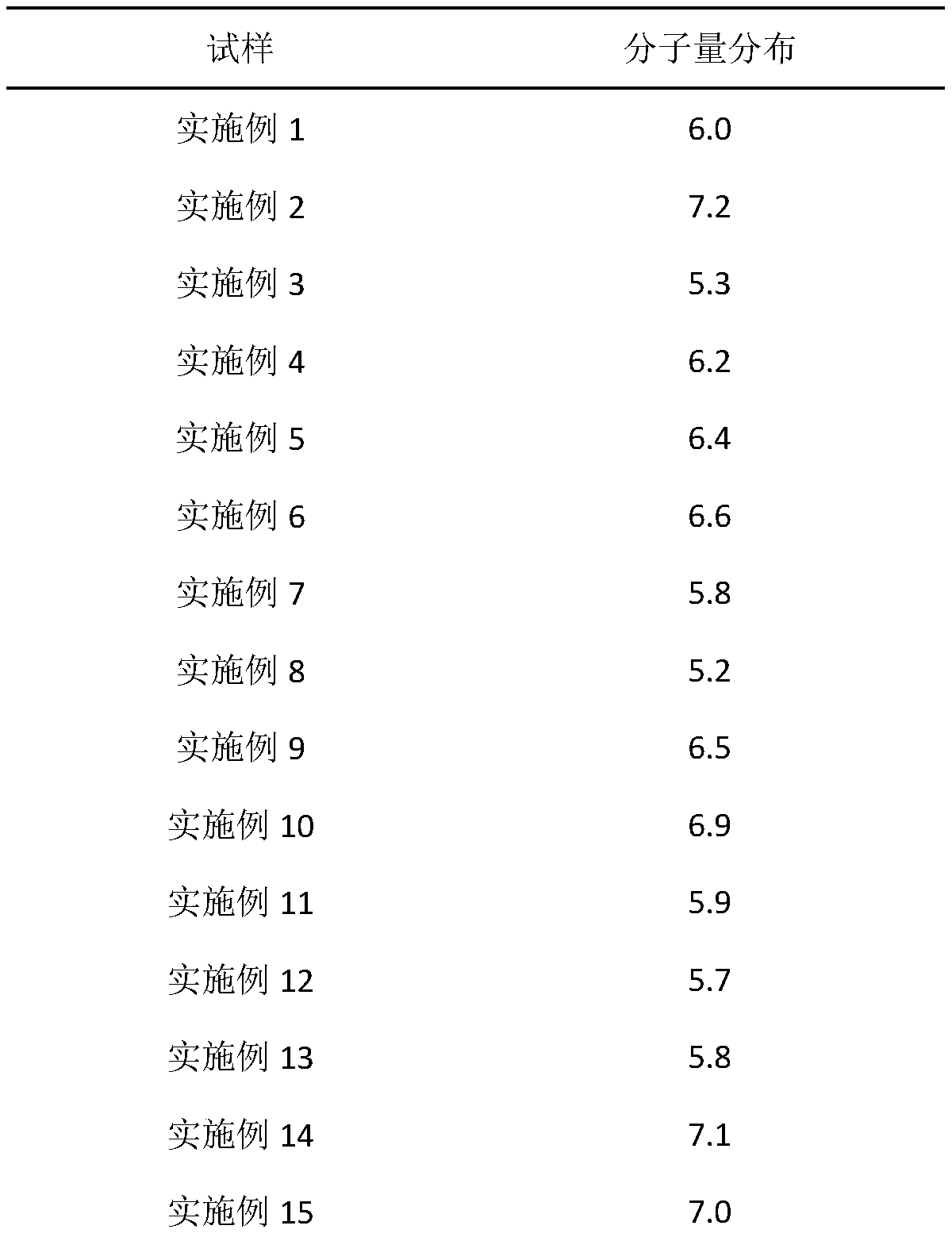

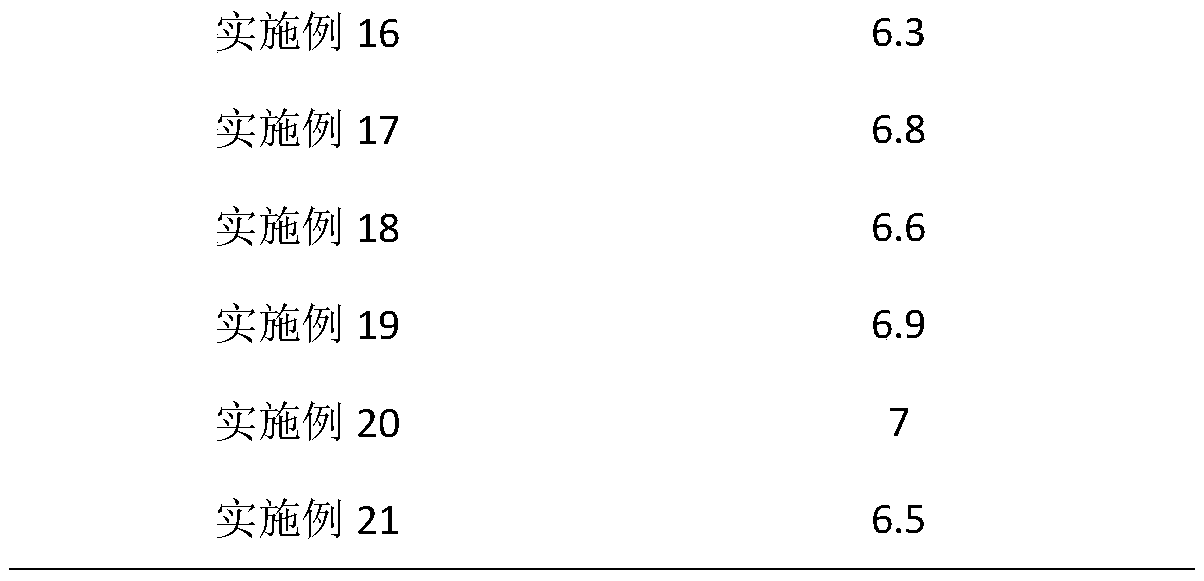

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com