High-thermal-conductivity polyetheretherketone electromagnetic shielding composite material and preparation method thereof

A polyether ether ketone and electromagnetic shielding technology, which is applied in shielding materials, magnetic field/electric field shielding, electrical components, etc., can solve the problems of difficult dispersion of filler agglomeration, small increase in thermal conductivity, and excessive filling volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

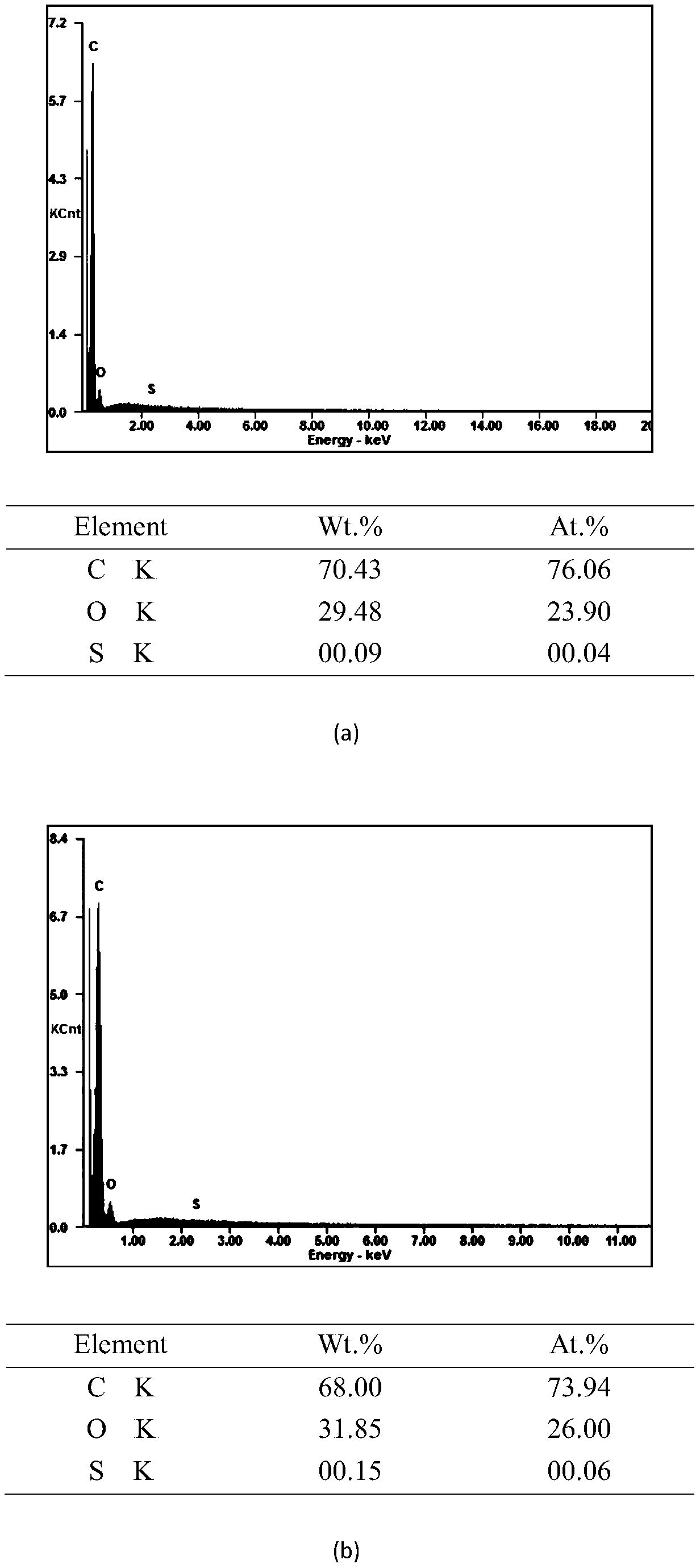

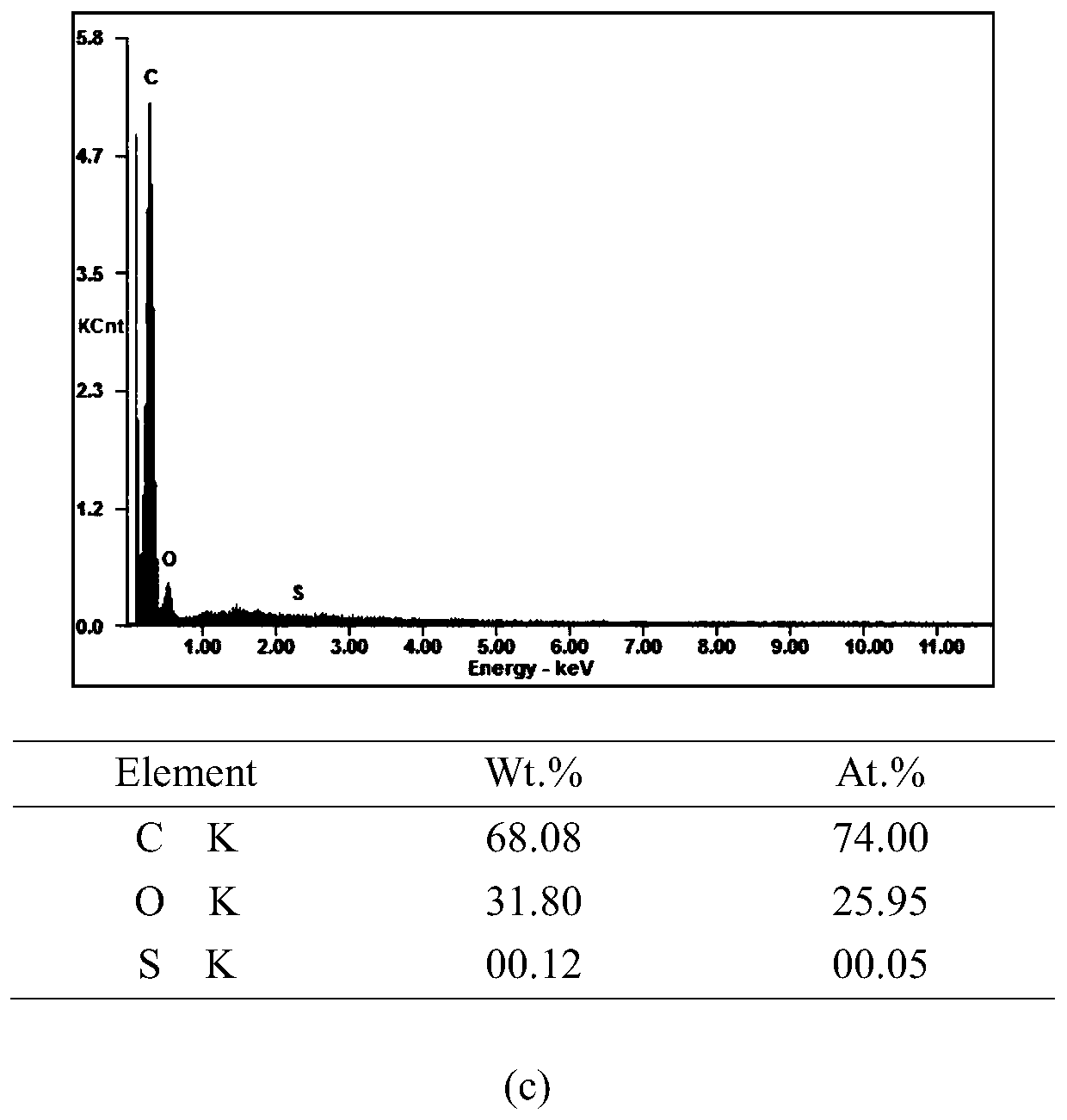

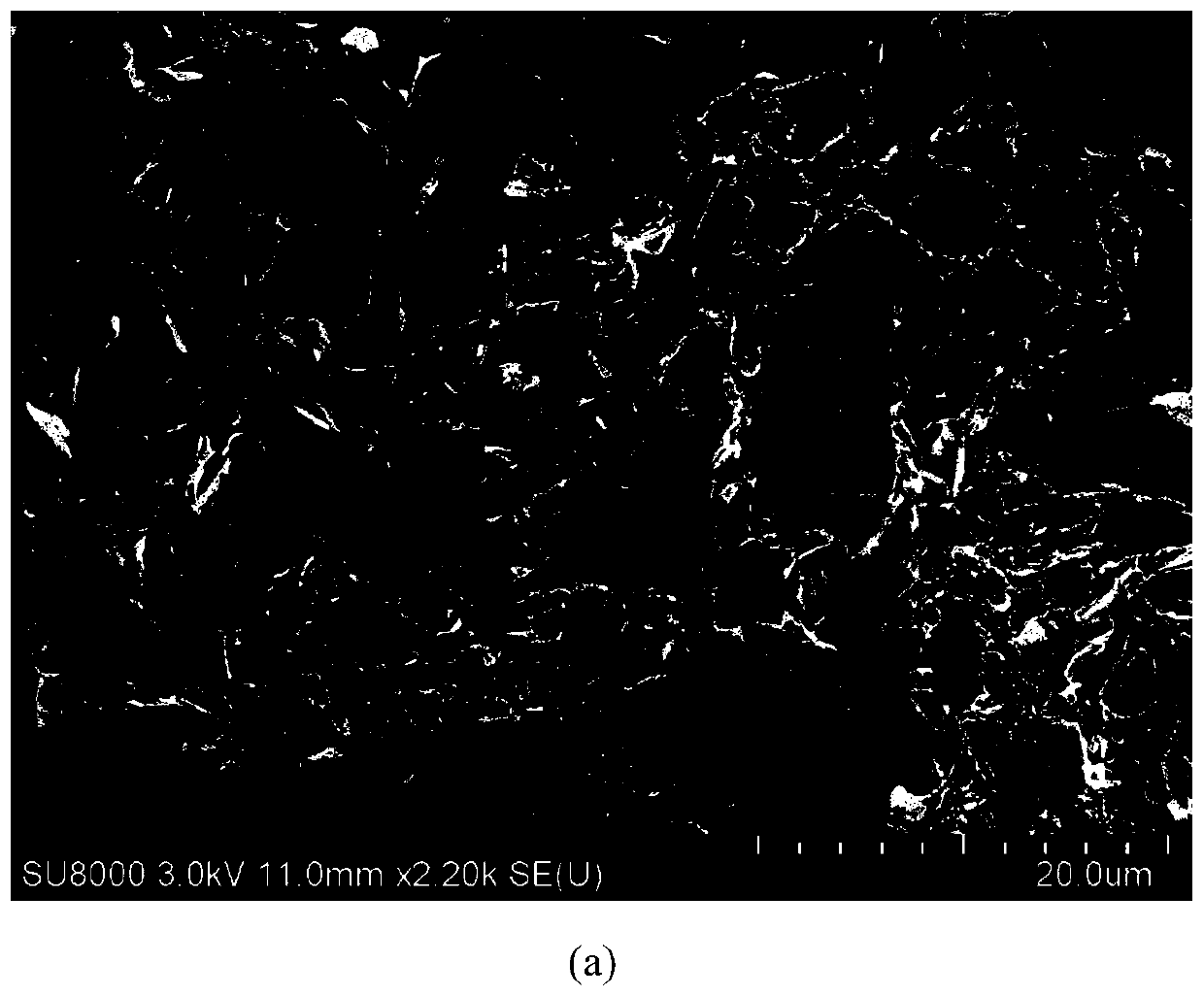

[0022] 1. Preparation of spherical core-shell structure high thermal conductivity filler

[0023] In this embodiment, a spherical core-shell structure high thermal conductivity filler with a particle size of 1.0 mm and a sulfonation degree of 40% is used. The specific operation is:

[0024] Dissolve 4,4'-difluorobenzophenone into 98wt.% concentrated sulfuric acid, and the mass ratio of 4,4'-difluorobenzophenone to concentrated sulfuric acid is 1:10. The reaction system was kept stirring at 100° C. for 10 h. The reaction was cooled to room temperature, and the reaction solution was poured into a large amount of ice water to cool. Then NaCl was added to the reaction solution until precipitation occurred, the product was filtered, washed repeatedly with deionized water until neutral, and dried to obtain 4,4'-difluoro-3,3'-disulfonic acid benzophenone.

[0025] Add 4,4'-difluorobenzophenone, 4,4'-difluoro-3,3'-disulfonic acid benzophenone, Hydroquinone and potassium carbonate,...

Embodiment 2

[0040] 1. Preparation of polyetheretherketone composites

[0041] In this embodiment, a spherical core-shell structure high thermal conductivity filler with a particle size of 2.0 mm and a sulfonation degree of 40% is used. The specific operation of the nucleophilic substitution reaction and the drying method is the same as in Example 1. The difference is that the sulfonated polyether ether ketone is cut using a spherical mold with a particle size of 2.0 mm to obtain spherical sulfonated polyether ether ketone particles with a particle size of 2.0 mm. Weigh the mass, and the mass of 100 spherical particles is 4.528g.

[0042] The electrostatic field treatment is the same as in Example 1. Weigh the mass, and the mass of 100 spherical core-shell structure high thermal conductivity fillers is 8.906g. Through calculation, the graphite adsorption mass of 100 core-shell structure high thermal conductivity fillers is 4.378g, with an average of 0.0438g graphite per adsorbed graphit...

Embodiment 3

[0048] 1. Preparation of polyetheretherketone composites

[0049] In this embodiment, a spherical core-shell structure high thermal conductivity filler with a particle size of 3.0 mm and a sulfonation degree of 40% is used. The specific operation of the nucleophilic substitution reaction and the drying method is the same as in Example 1. The difference is that the sulfonated polyether ether ketone is cut using a spherical die with a particle size of 3.0 mm to obtain spherical particles with a particle size of 3.0 mm. Weigh the mass, and the mass of 50 spherical particles is 7.643g.

[0050] The electrostatic field treatment is the same as in Example 1. Weigh the mass, and the mass of 50 spherical core-shell structure high thermal conductivity fillers is 13.857g. Through calculation, the graphite adsorption mass of 50 core-shell structure high thermal conductivity fillers is 6.214g, with an average of 0.124g graphite per adsorbed graphite, and the mass fraction of graphite o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com