Primer surfacer for automobiles, preparation method and application thereof

A painting and automotive technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as increasing painting costs and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

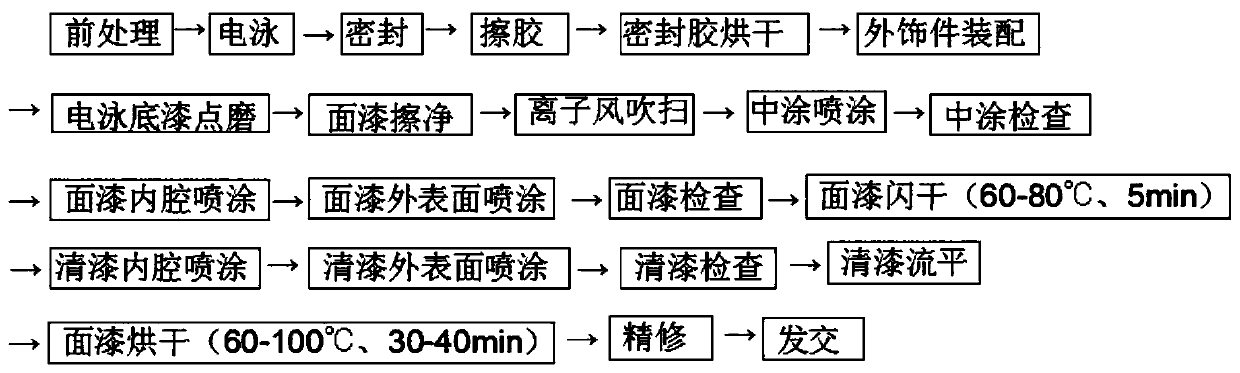

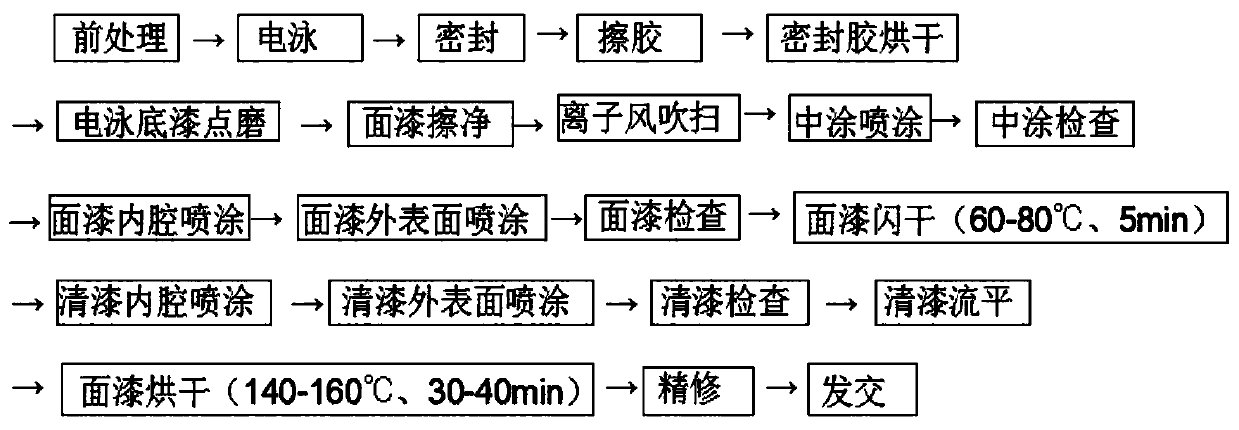

Method used

Image

Examples

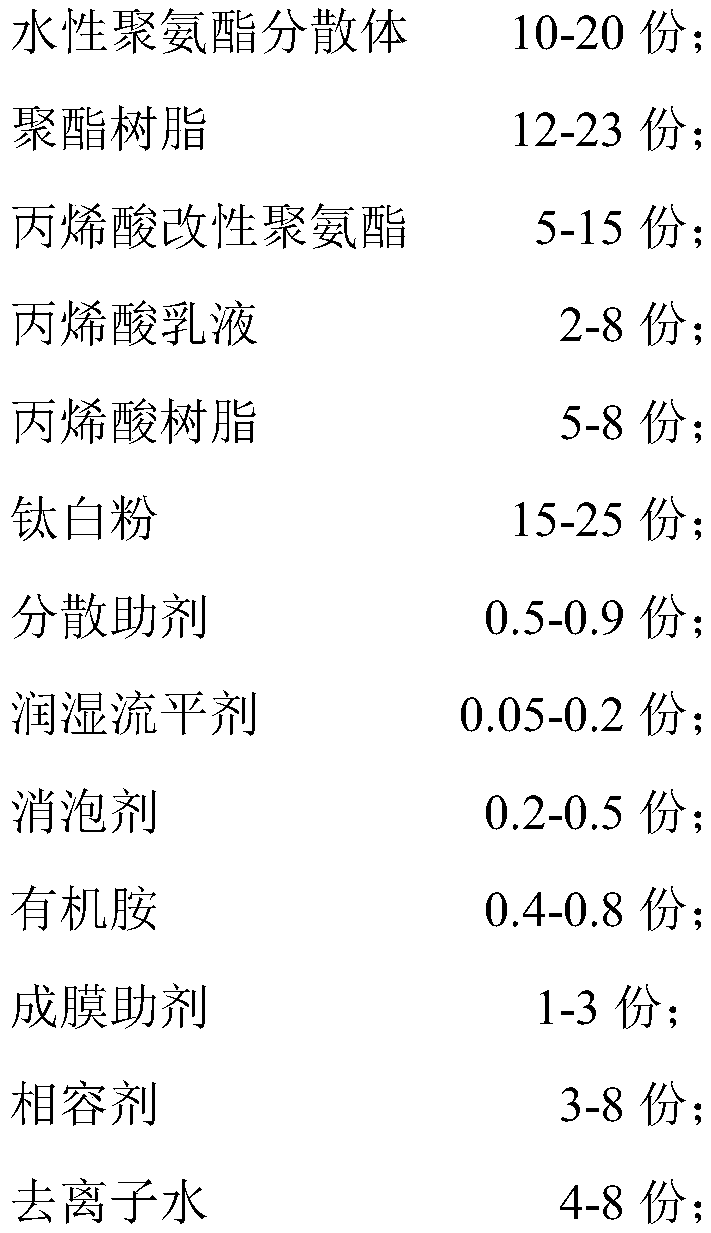

Embodiment 1

[0049] A primer for automobiles, including A-component and B-component (curing agent). A component includes the following raw materials: water-based polyurethane dispersion, polyester resin, acrylic modified polyurethane, acrylic emulsion, acrylic resin, titanium dioxide, dispersion aid, wetting and leveling agent, defoamer, organic amine, film-forming aid agent, compatibilizer, deionized water (the parts by weight of each component are shown in formula 1 in the following table 1).

[0050] Table 1: The composition ratio of the A component of the intermediate coating paint in Examples 1-8 and Comparative Examples 1-2

[0051]

[0052] In the above table, TW-008, TW-401, TW201, and TW-103 are all water-based resin products produced by Hunan Bonforte New Material Technology Co., Ltd., and their specific indicators are shown in Table 2 below (the same below).

[0053] Among them, TW-008 is an aliphatic polyurethane polyol resin with a molecular weight Mn of 5000 and a polydis...

Embodiment 2

[0069] A kind of intermediate paint that is used for automobile, its composition and preparation method are identical with embodiment 1.

[0070]A kind of finish paint that is used for automobile, finish paint is divided into two layers of white surface and pearly finish, the formula of C component in the formula of white face and pearly finish two-layer finish coat and the weight parts of each formula are respectively as formula 2, in table 3 Recipe 3 is shown. For its preparation method, refer to the preparation method of component C of the topcoat in Example 1.

Embodiment 3

[0072] A kind of intermediate paint that is used for automobile, its composition and preparation method are identical with embodiment 1, but the composition of A component is formula 2 in table 1.

[0073] A kind of finish paint that is used for automobile, its composition and preparation method are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com