CO2 cross-critical air source heat pump system for efficient utilization of multi-terminal low-temperature heat energy

An air source heat pump and transcritical technology, which is applied in heating systems, hot water central heating systems, heat pumps, etc., can solve the problems of high cost for small households, little significance for energy saving, complex systems, etc. Bathroom hot water demand, the effect of broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

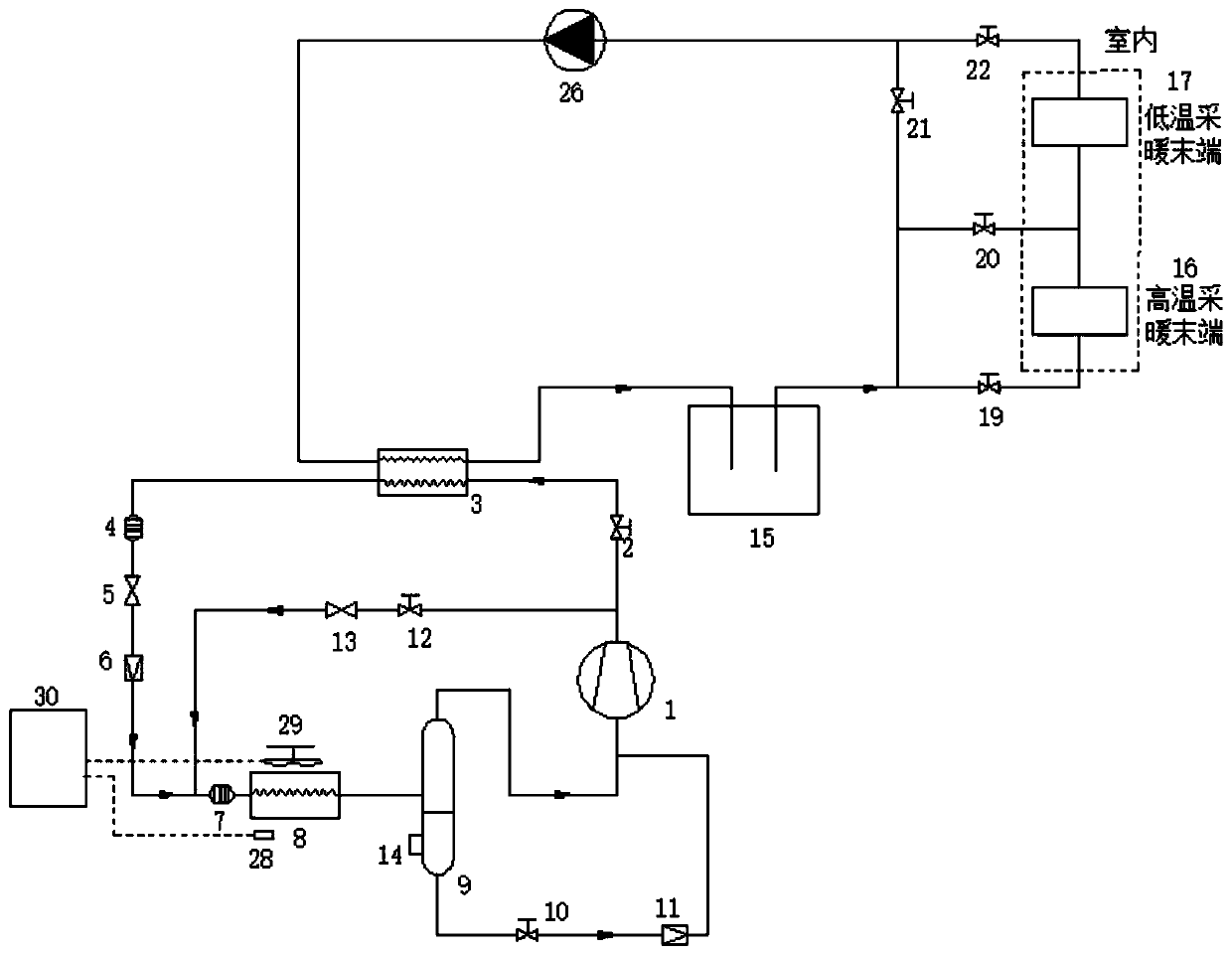

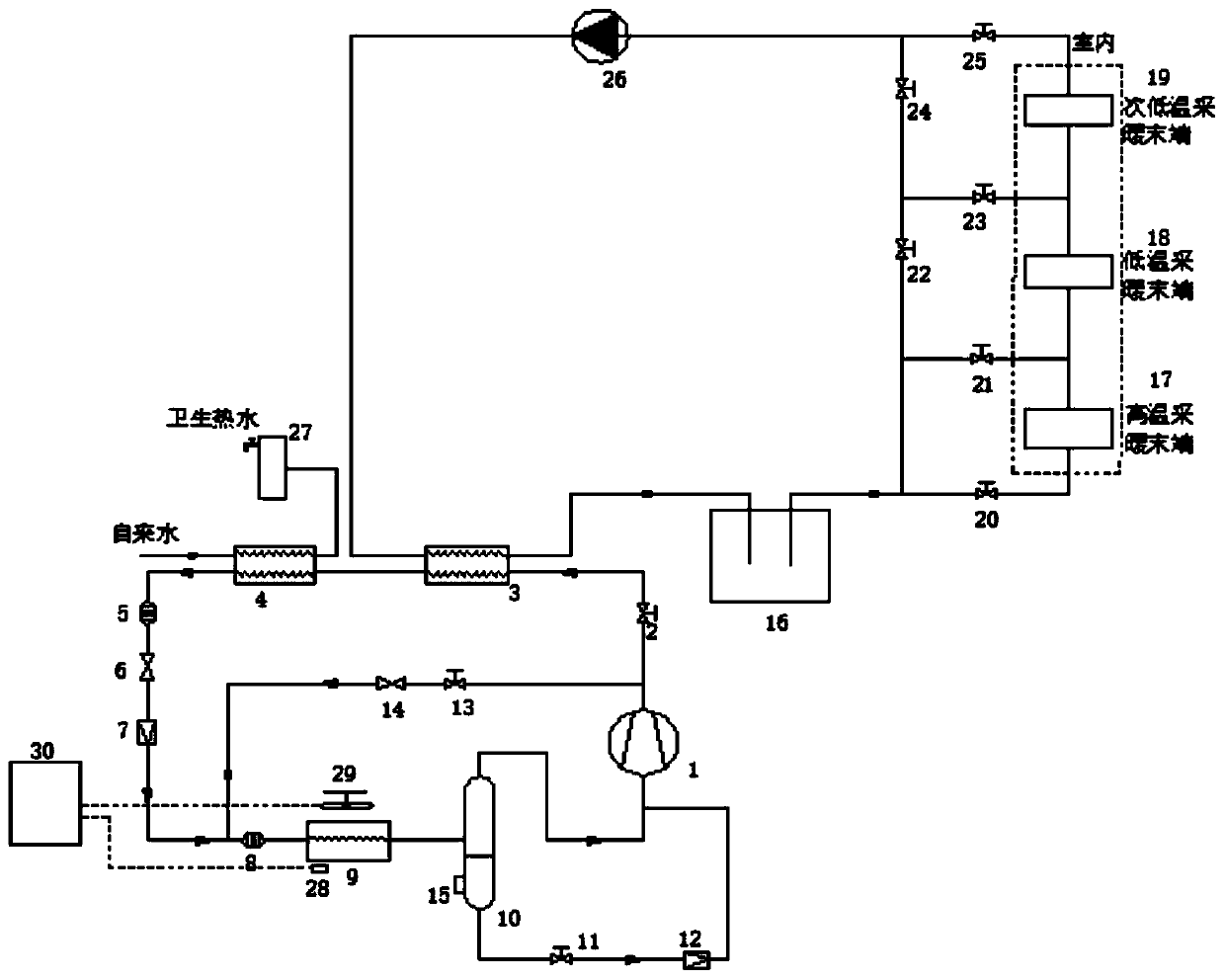

[0028] Embodiment 1: Normal working mode.

[0029] Such as figure 1 As shown, the normal working mode of the system has two cycles, heat pump cycle and water cycle. In the water circulation system under normal working mode, the fifth cut-off valve 21 and the sixth cut-off valve 22 are closed, the fourth cut-off valve 20 and the seventh cut-off valve 23 are opened, and the high-temperature heating terminal 17 is connected to the low-temperature heating terminal 18 and are respectively in different positions. room, the two are connected in series to work, absorb the heat released in the air cooler 3, and then heat the room. The low-temperature heating terminal (such as: floor radiant heating terminal) can be installed in the bathroom, kitchen, storage room, etc. that are not used for a long time, and the high-temperature heating terminal (such as: radiator) can be installed in the bedroom that needs to ensure comfort, so as to ensure the best Good heating comfort. The high-te...

Embodiment 2

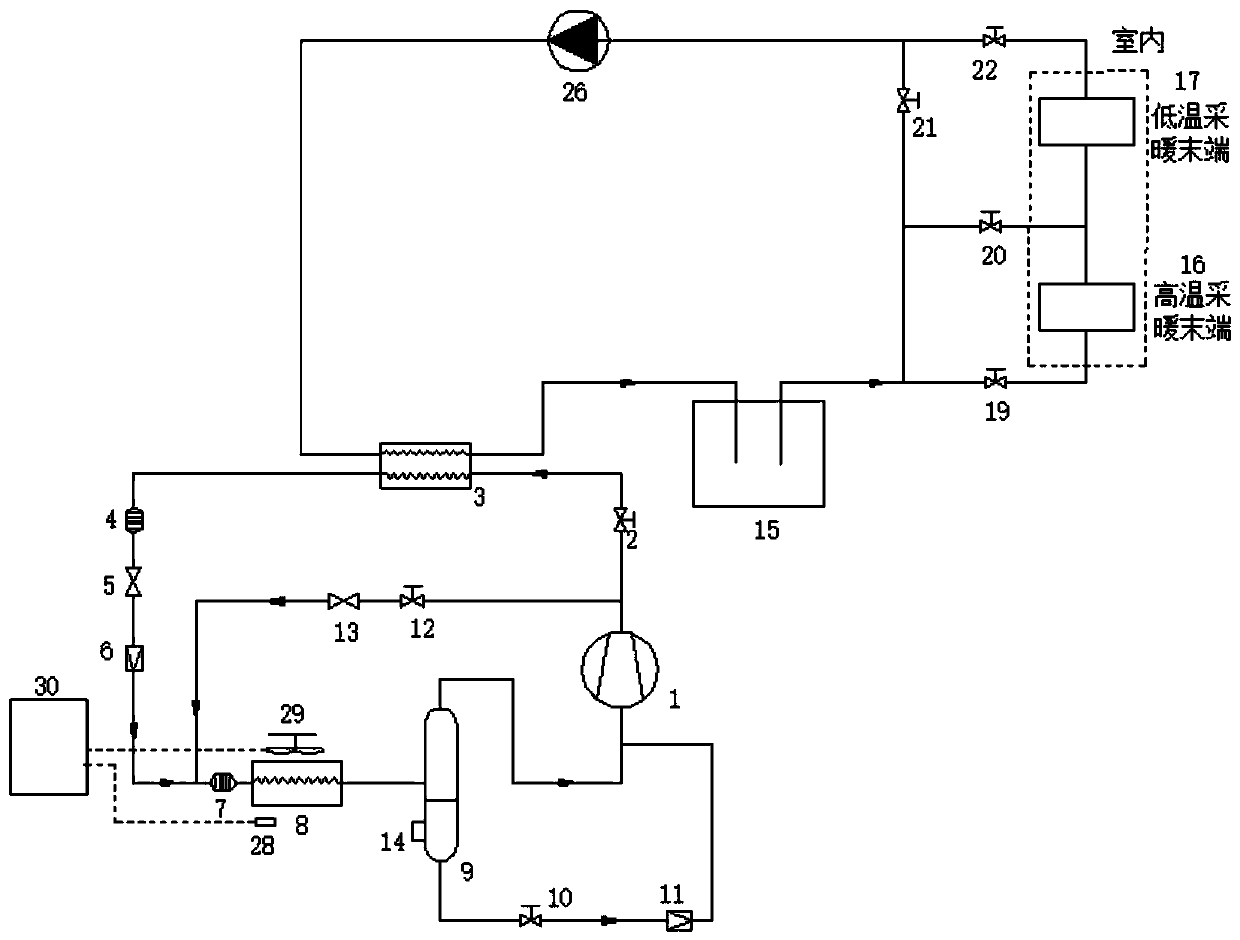

[0030] Example 2: Low-temperature heating terminal working mode or high-temperature heating terminal working mode

[0031] Such as figure 1 As shown, in some special cases the occupants may stay in one room so it is not necessary for both heating devices to be activated. In the present invention, four shut-off valves are added in the water circulation system to control two heating equipments. For example, only the low-temperature heating end is required to work but not the high-temperature heating end, that is, the fourth and sixth stop valves are closed, and the fifth and seventh stop valves are opened. When only the high-temperature heating end is required to work but not the low-temperature heating end, Close the seventh stop valve and open the fourth, fifth and sixth stop valves. At the same time, the second air cooler is also working, continuously heating tap water to produce sanitary hot water and store it in the water tank, such as figure 2 This part can also be rem...

Embodiment 3

[0032] Example 3: Hot gas bypass defrosting mode

[0033] Such as figure 1 As shown, when the temperature of the surface of the evaporator 9 is lower than the dew point temperature in the air, the water vapor in the air will gradually condense on the surface of the evaporator to form a frost layer, which is a very common phenomenon in winter in the north. In the present invention, the hot gas bypass defrosting system is used for CO 2 In the transcritical air source heat pump system, when the frost layer on the evaporator is too thick to affect the work, the fourth cut-off valve is closed and the fifth cut-off valve is opened. At this time, the high-temperature CO discharged from compressor 1 2 The refrigerant will flow through the fifth cut-off valve and directly enter the air-cooled evaporator for defrosting, and the CO after heat exchange 2 After the refrigerant flows through the gas-liquid separator 10, it enters the compressor to complete the cycle.

[0034] During the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com