Beam shaping vertical cavity surface emitting laser integrated with high-contrast grating and simulation method thereof

A vertical cavity surface emission and beam shaping technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of complex manufacturing process, poor mechanical stability, difficult coupling efficiency, etc., and achieve simple manufacturing process and easy simulation calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

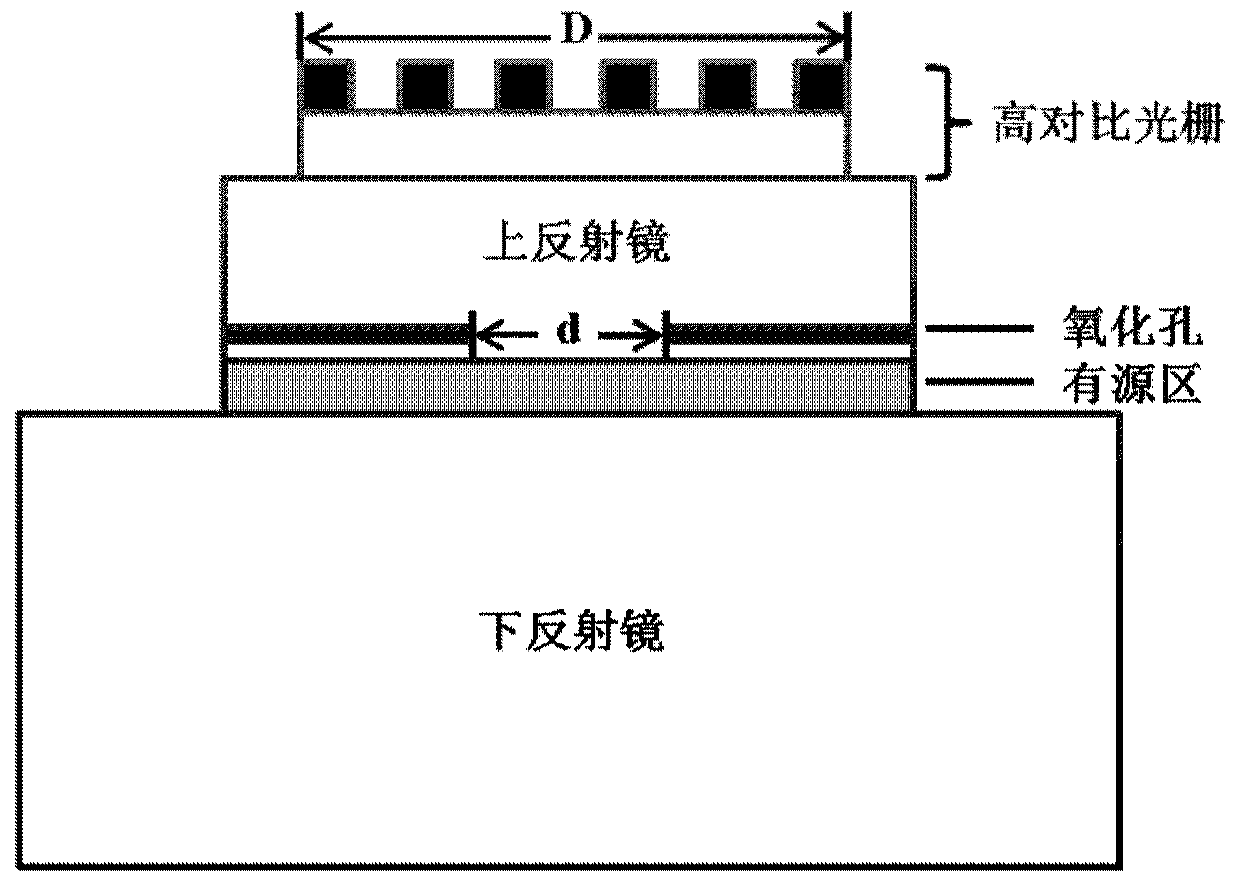

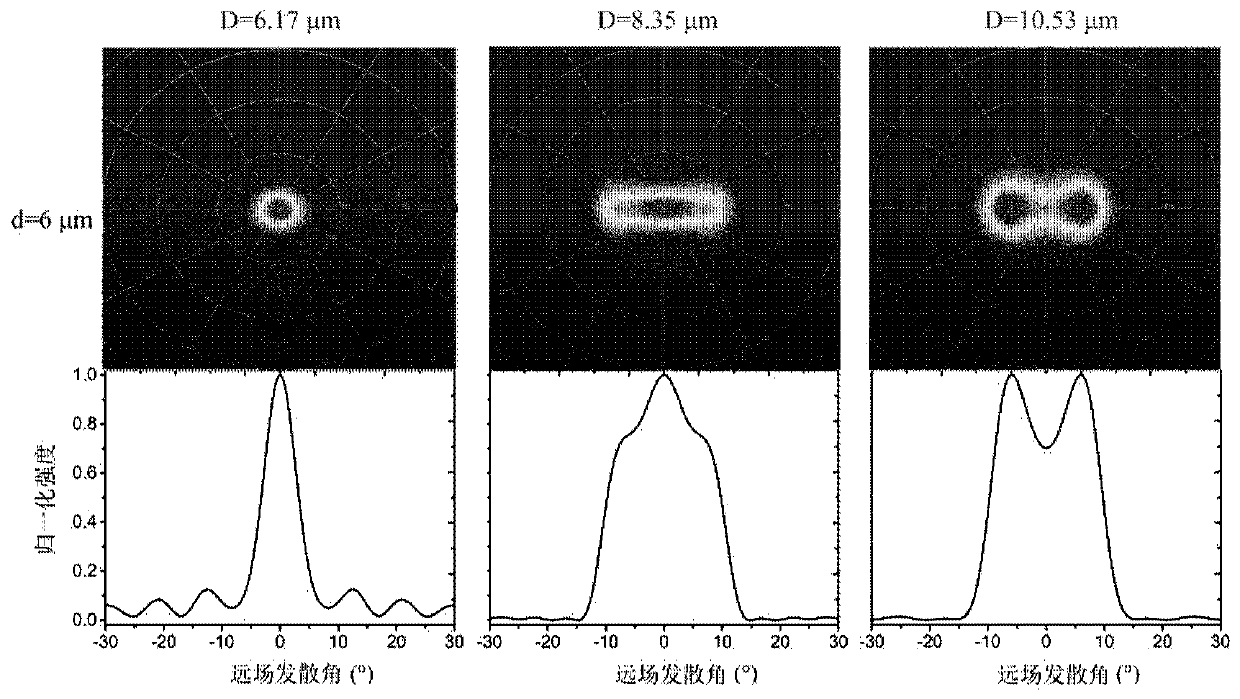

[0025] The invention discloses a beam-shaping vertical-cavity surface-emitting laser integrated with a high-contrast grating and a simulation method thereof. The beam-shaping vertical-cavity surface-emitting laser is composed of a vertical-cavity surface-emitting laser and a high-contrast grating. The oxidized hole size of the cavity surface emitting laser obtains output beams of different shapes. The invention can achieve single-lobe, double-lobe and other beam outputs without resorting to an external beam shaping system.

[0026] Specifically, the present invention provides a beam-shaping vertical-cavity surface-emitting laser integrating a high-contrast grating, including:

[0027] The vertical cavity surface emitting laser includes a lower reflector, an active area, an oxidation hole and an upper reflector, and the lower reflector, the active area, the oxidation hole and the upper reflector are arranged adjacently in sequence;

[0028] A high-contrast grating located on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com