Fully automatic assembly line production equipment for injector

A technology for producing equipment and syringes, which is applied in the field of full-automatic assembly line production equipment for syringes, can solve the problems of wasting manpower, time and space, covering a large area, and taking a long time to deliver products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

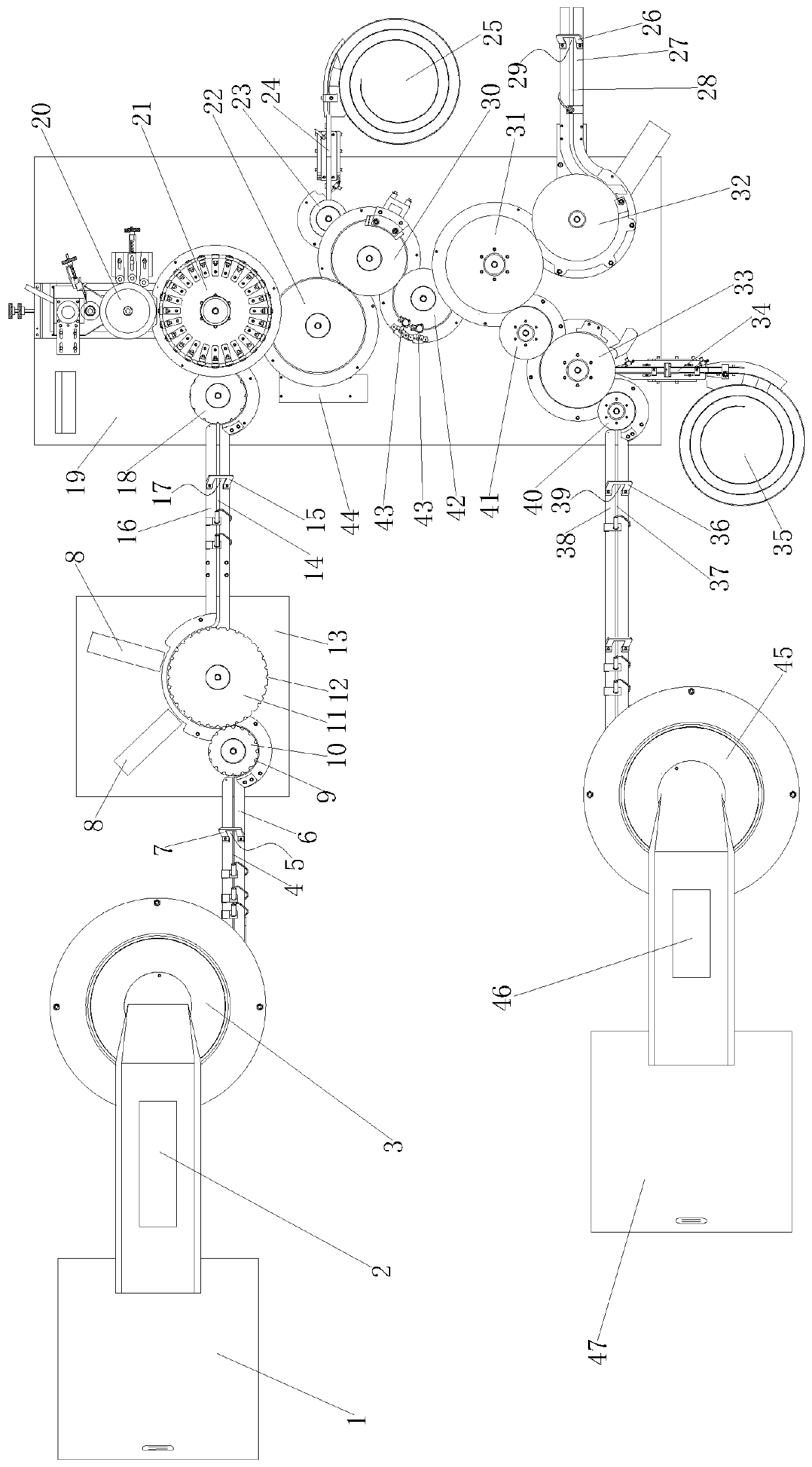

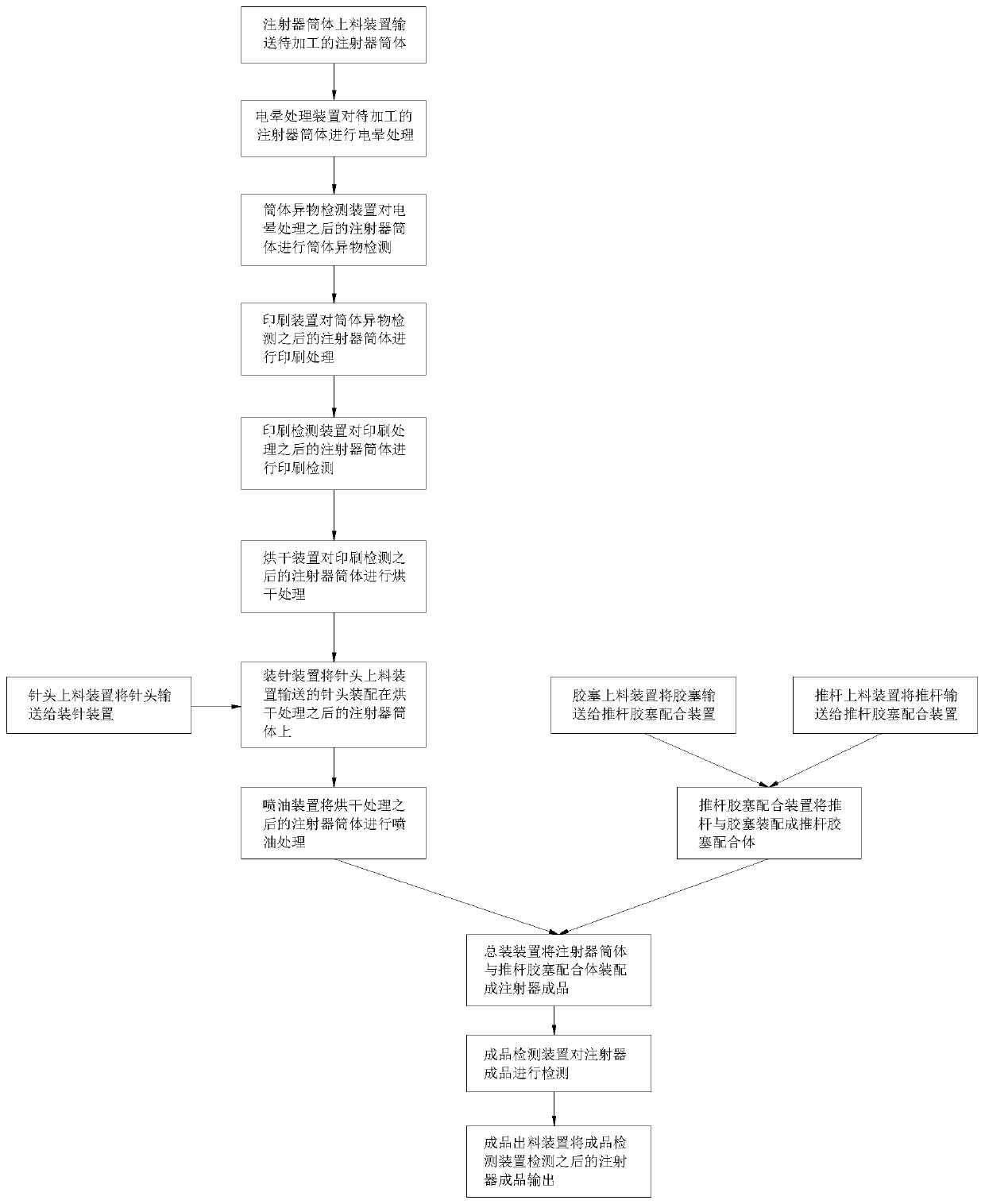

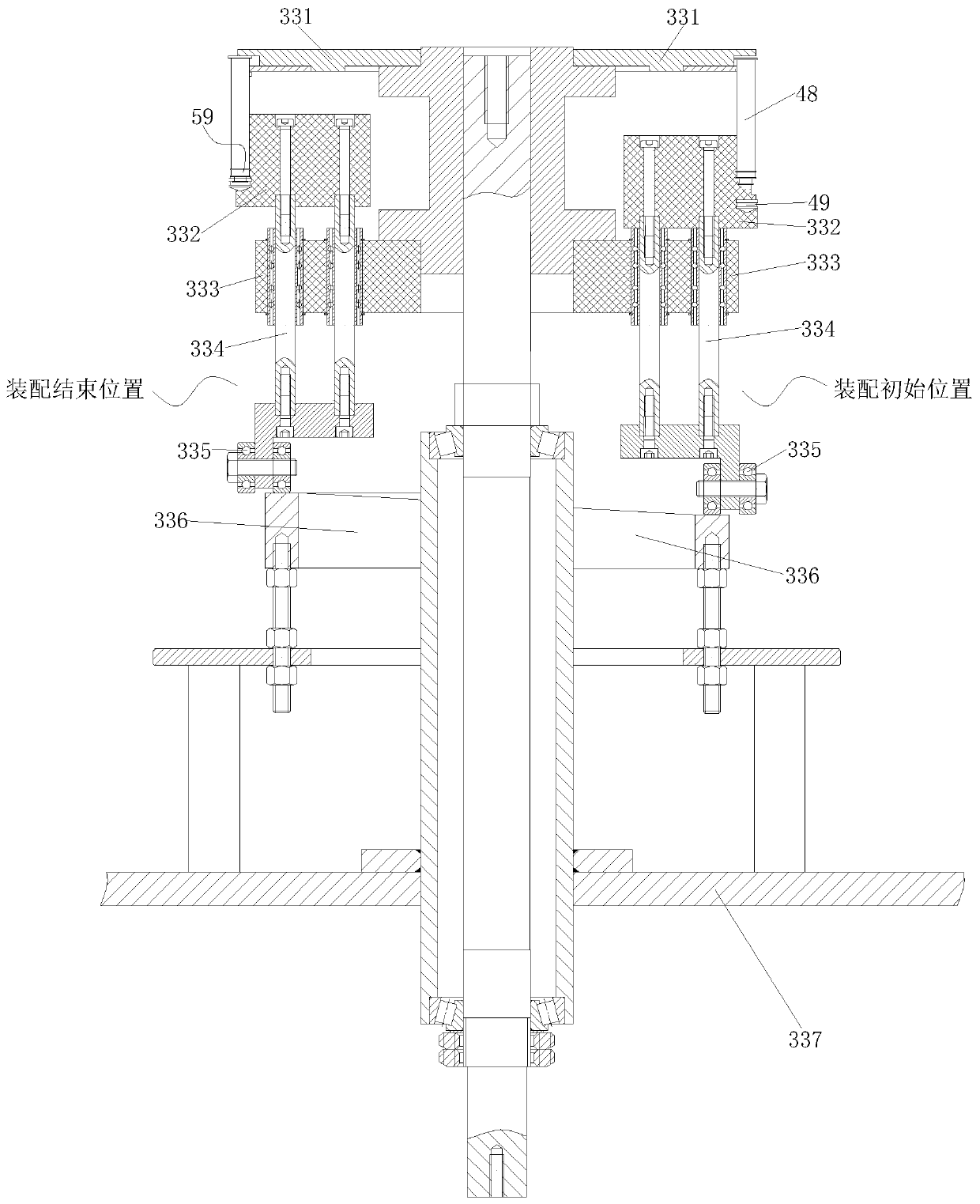

[0053] Syringe automatic assembly line production equipment, such as Figure 1-12 As shown, it includes a syringe cylinder feeding device, a corona treatment device, a cylinder foreign matter detection device, a printing device, a drying device, a needle feeding device, a needle loading device, an oil injection device, Push rod feeding device, rubber plug feeding device, push rod rubber plug matching device 33, assembly device 31, finished product inspection device, syringe barrel feeding device, corona treatment device, cylinder foreign matter detection device, printing device, drying The drying device, the needle feeding device, the needle loading device, the fuel injection device, the push rod feeding device, the rubber plug feeding device, the push rod rubber plug matching device 33, the assembly device 31, and the finished product testing device are respectively composed of respective racks or Workbench support; specifically, the syringe cylinder feeding device is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com