Method for preparing emulsion by gas-driven emulsification

A gas-driven, emulsion technology, used in chemical instruments and methods, chemical/physical processes, dissolution, etc., can solve the problems of uneven droplet particle size and high production energy consumption, and achieve easy large-scale industrial production and low equipment requirements. , good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

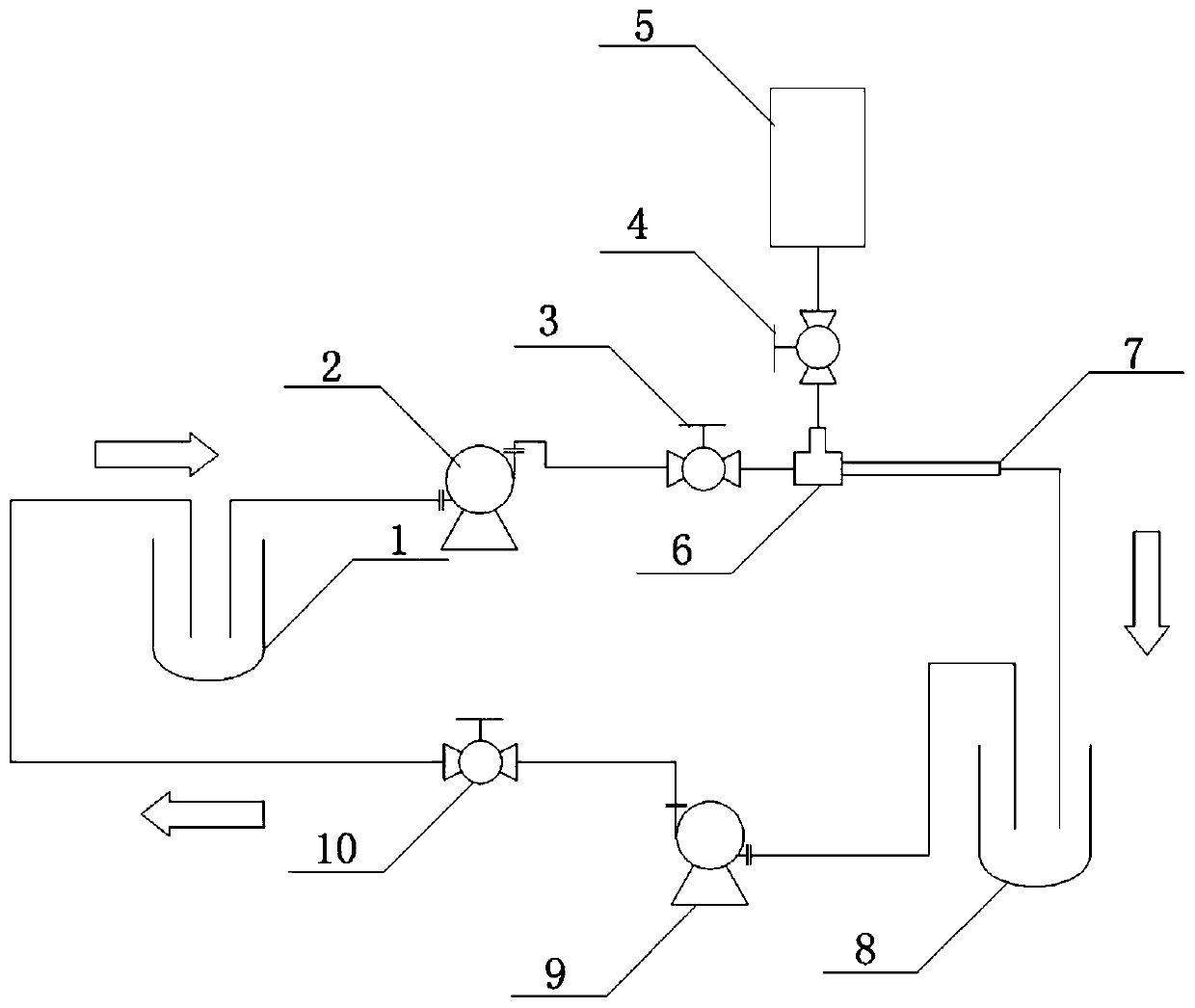

Method used

Image

Examples

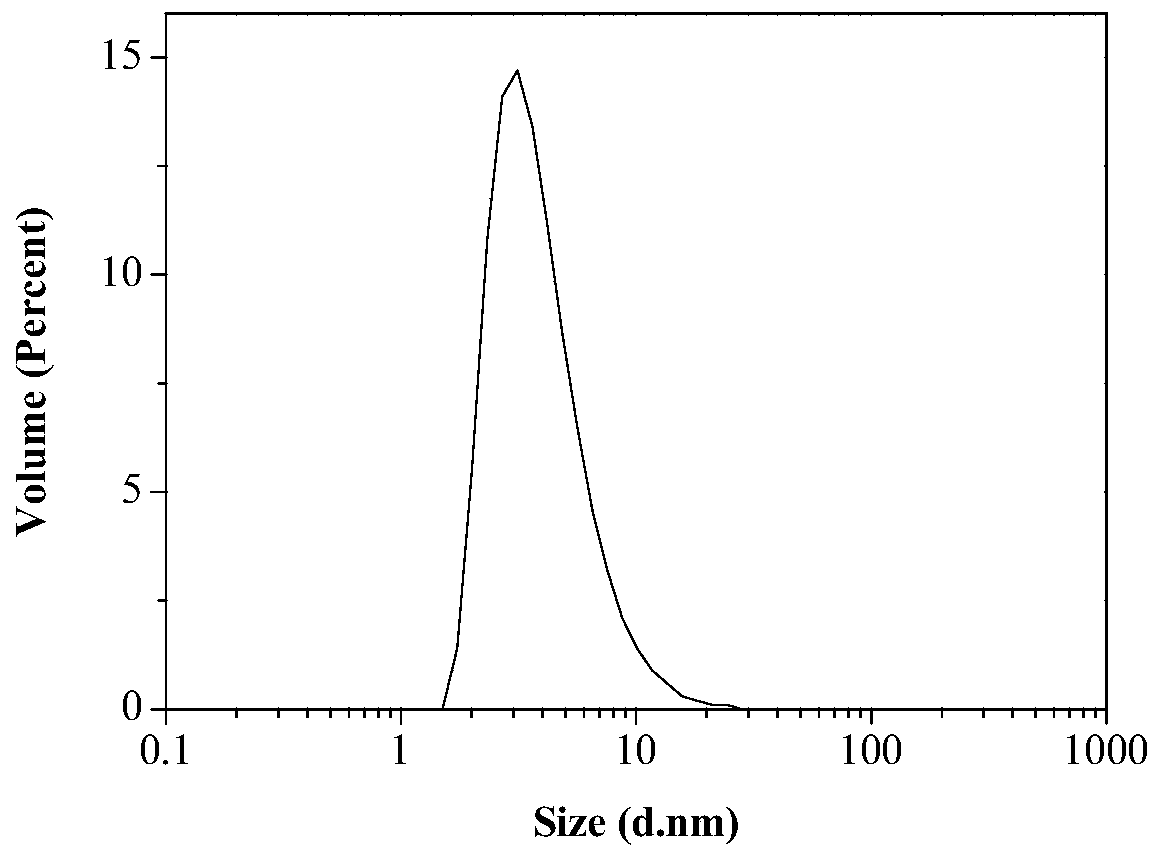

Embodiment 1

[0022] A kind of method that gas-driven emulsification prepares emulsion, concrete steps are: (1) take by weighing 10g squalane, 0.1g is mixed by the surfactant of fatty alcohol polyoxyethylene ether and glyceryl monostearate, wherein fat The mass ratio of alcohol polyoxyethylene ether to glyceryl monostearate is 1:1, add squalane and surfactant to 100g water at the same time, heat and stir at 50°C and 100rpm stirring speed for 20min, and mix well (2) After the solution system in step (1) is cooled to 30°C, use a pump to send the solution system into the gas-driven emulsification element with a flow rate of 5L / h, and use an air compressor to send air at 100L / h Enter the gas to drive the emulsification element, wherein the three hole diameters of the tee in the emulsification element are all 5mm, the inner diameter of the slender tube is 2mm, and the length of the slender tube is 30cm, and the emulsified squalane emulsion is obtained after emulsification; (3) The squalane emuls...

Embodiment 2

[0024] A method for preparing an emulsion by a gas-driven emulsifying element, the specific steps are: (1) Weighing 10g of simethicone oil, 4g of polyoxyethylene alkyl ester of fatty acid and polyoxyethylene sorbitan monostearate mixed Surfactant, wherein the mass ratio of fatty acid polyoxyethylene alkyl ester and polyoxyethylene sorbitan monostearate is 3:1, simethicone and surfactant are added to 90g water at the same time, at a temperature of 90°C , at a stirring speed of 600rpm, heat and stir for 60min, and mix evenly; 2) After the solution system in step 1) is cooled to 25°C, use a pump to send the solution system into the gas-driven emulsification element at a flow rate of 10L / h, and simultaneously use The air compressor sends air at 600L / h into the gas-driven emulsification element, in which the diameter of the three holes in the emulsification element is 8mm, the inner diameter of the slender tube is 1mm, and the length of the slender tube is 100cm. Finally, obtain a ...

Embodiment 3

[0026] A method for preparing an emulsion by gas-driven emulsifying elements, the specific steps are: (1) weighing 10 g of ginger oil and 1 g of sorbitan stearate. Add ginger oil and sorbitan stearate to 10g of water at the same time, heat and stir for 100min at a temperature of 70°C and a stirring speed of 1000rpm, and mix well; (2) Cool the solution system in step (1) to 5°C Finally, use a pump to send the solution system into the gas-driven emulsification element at a flow rate of 20L / h, and use an air compressor to send air into the gas-driven emulsification element at a rate of 800L / h, wherein the three holes in the emulsification element are Aperture is 5mm, and the internal diameter of slender tube is 2mm, and the length of slender tube is 2cm, obtains the ginger oil emulsion of primary emulsification after emulsification; Enter the gas to drive the emulsification element, repeat the emulsification operation, and circulate 10 times to obtain the ginger oil emulsion whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com