Polyethylene hydrophobic material and preparation method thereof

A hydrophobic material, polyethylene technology, applied in the field of polymer materials, can solve the problems of high cost, unfriendly environment, and inability to realize continuous large-scale industrialization, and achieve the effect of low cost, regularity and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0044] (1) First, dry polypropylene (PP) particles at 60°C in an oven for 8 hours, then add them to the primary melt injection unit barrel of the multi-melt multiple injection molding equipment for melting and plasticization, as a primary injection melt to be used;

[0045] (2) Polyethylene (PE) pellets were dried in an oven at 60°C for 8 hours and then added to the barrel of the secondary melt auxiliary injection platform of the multi-melt multiple injection molding equipment for melting and plasticization, as a secondary The first injection of melt is ready for use;

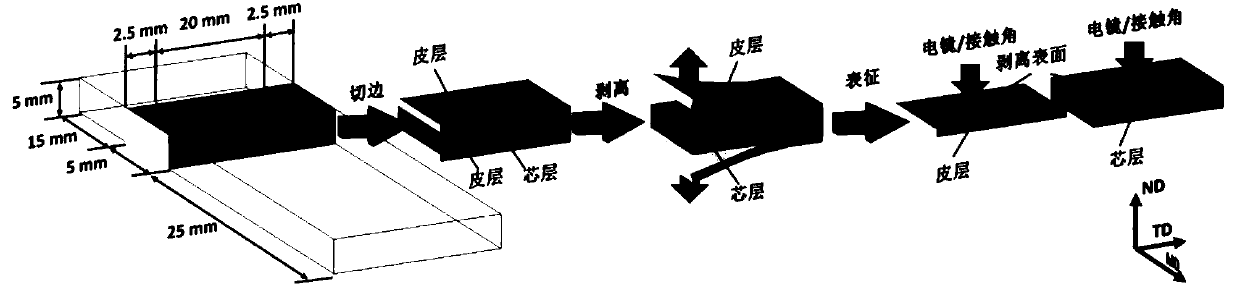

[0046] (3) The PP primary melt in step (1) is short-shot into the cavity to half-fill the cavity, and then the PE secondary melt in step (2) is injected into the cavity so that the secondary PE melt The body pushes and penetrates the PP melt once and fills the entire cavity; among them, the process parameters of multi-melt multiple injection molding are set as: Body injection speed is 15-56.7ccm / s, primary PP...

Embodiment 1

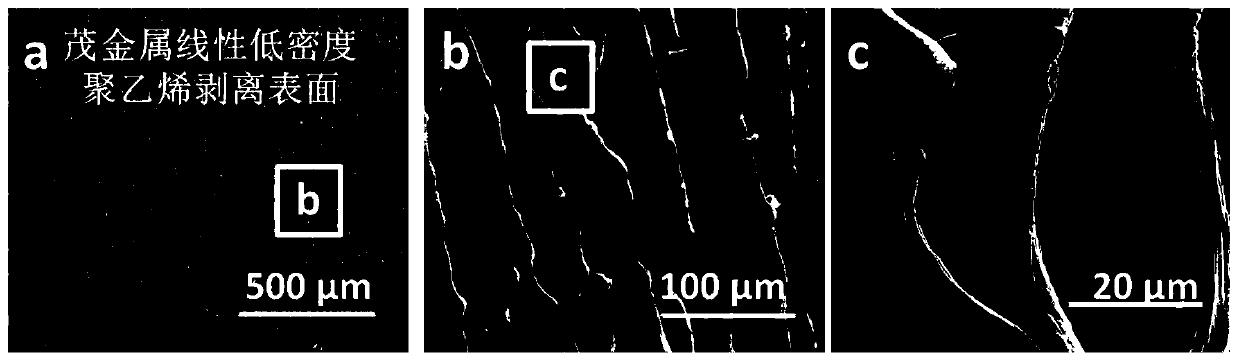

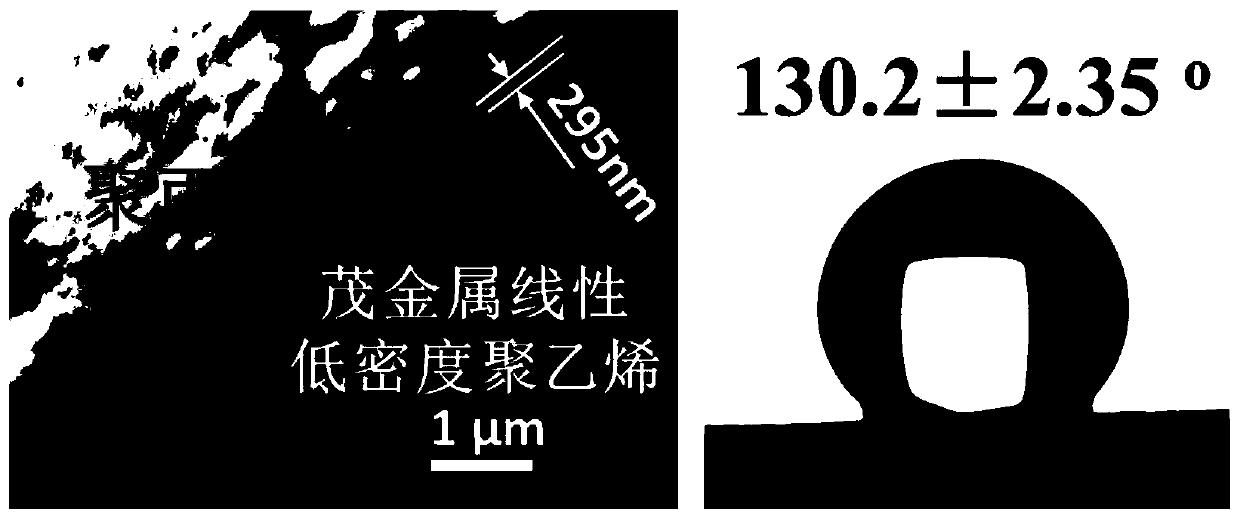

[0050] Isotactic polypropylene (iPP, grade PPH-T03, produced by China Maoming Petrochemical Company) and metallocene-catalyzed linear low-density polyethylene (mLLDPE, grade 3578CB, produced by ExxonMobil Corporation, with a weight-average molecular weight of M w =1.3×10 5 g / mol, molecular weight distribution coefficient D=1.74) respectively added to the primary melt injection unit of the multi-melt multiple injection molding equipment and the barrel of the secondary melt injection platform for plasticization, and finally as the primary melt Perform multi-melt multiple injection molding steps with the secondary melt, and the molding process is:

[0051] (1) First, short-shot the iPP melt plasticized by the primary injection unit into the cavity along the injection flow direction (MD), the primary injection speed is 57.7ccm / s, the primary injection pressure is 2270bar, and the primary injection temperature is 200°C; Then inject the mLLDPE melt plasticized by the secondary auxi...

Embodiment 2

[0059] Isotactic polypropylene (iPP, brand name PPH-T03, produced by China Maoming Petrochemical Company) and metallocene-catalyzed polyethylene (mPE, brand name S1498A, produced by Exxon Mobil Corporation, weight average molecular weight M w =1.0×10 5 g / mol, molecular weight distribution coefficient D=1.82) were respectively added to the primary melt injection unit of the multi-melt multiple injection molding equipment and the barrel of the secondary melt injection station for plasticization, and finally used as the primary melt Perform multi-melt multiple injection molding steps with the secondary melt, and the molding process is:

[0060](1) First, shortly shoot the iPP melt plasticized by the injection unit along the MD, the injection speed is 57.7ccm / s, the injection pressure is 2270bar, and the injection temperature is 200°C; then go to the mold along the MD The mPE melt plasticized by the secondary auxiliary injection platform is injected into the cavity, the secondary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com