Preparation method and application of electrolyte-treated laboratory metal potassium sheet

A laboratory-use, metal potassium technology, applied in the direction of circuits, electrical components, battery electrodes, etc., can solve the size, thickness is difficult to unify, limit the scientific research and market application of potassium ion batteries, metal potassium soft sticky, etc. problems, to achieve the effects of reducing the difficulty of preparation, efficient and convenient preparation methods, and shortening the time spent on preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The electrolyte of this embodiment uses 1M KPF 6 in DME=100%.

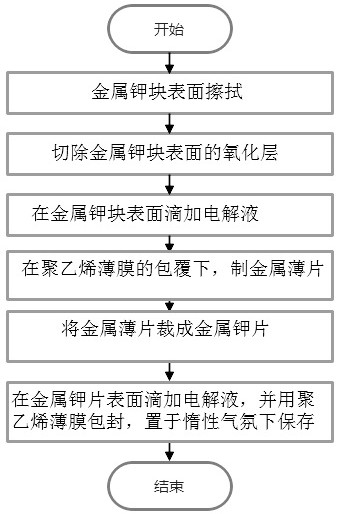

[0035] A kind of preparation method of the laboratory metal potassium sheet of electrolyte treatment, comprises the following steps:

[0036] Step 1, in a glove box filled with an inert atmosphere (argon) (H 2 O, O 2 <<1ppm), take out the metal potassium block, and wipe off the residual kerosene on the surface of the metal potassium block with a dust-free paper;

[0037] Step 2, on the acrylic plate, use a stainless steel knife to remove the oxide layer on the surface of the wiped potassium metal block;

[0038] Step 3, use a 200μL pipette to pipette a certain amount of 1M KPF 6 in DME=100% dropwise on the surface of the pretreated potassium metal block;

[0039] Step 4, under the coating of polyethylene film, the metal potassium block is manually rolled to a metal sheet with a certain thickness by means of a metal aluminum rod;

[0040] Step 5, cutting the rolled metal sheet into metal discs with a...

Embodiment 2

[0045] The electrolyte in this embodiment uses 1M KFSI in DME=100%.

[0046] A kind of preparation method of the laboratory metal potassium sheet of electrolyte treatment, comprises the following steps:

[0047] Step 1, in a glove box filled with an inert atmosphere (argon) (H 2 O, O2 <<1ppm), take out the metal potassium block, and wipe off the residual kerosene on the surface of the metal potassium block with a dust-free paper;

[0048] Step 2, on the acrylic plate, use a stainless steel knife to remove the oxide layer on the surface of the wiped potassium metal block;

[0049] Step 3, use a 200 μL pipette to pipette a certain amount of 1M KFSI in DME=100% dropwise on the surface of the pretreated potassium metal block;

[0050] Step 4, under the coating of polyethylene film, the metal potassium block is manually rolled to a metal sheet with a certain thickness by means of a metal aluminum rod;

[0051] Step 5, cutting the rolled metal sheet into metal discs with a diamet...

Embodiment 3

[0056] The electrolyte in this example uses 1M KFSI in EC: DEC=1:1 (V / V).

[0057] A kind of preparation method of the laboratory metal potassium sheet of electrolyte treatment, comprises the following steps:

[0058] Step 1, in a glove box filled with an inert atmosphere (argon) (H 2 O, O 2 <<1ppm), take out the metal potassium block, and wipe off the residual kerosene on the surface of the metal potassium block with a dust-free paper;

[0059] Step 2, on the acrylic plate, use a stainless steel knife to remove the oxide layer on the surface of the wiped potassium metal block;

[0060] Step 3, use a 200 μL pipette to pipette a certain amount of 1M KFSI in EC: DEC=1:1 (V / V) and drop it on the surface of the pretreated potassium metal block;

[0061] Step 4, under the coating of polyethylene film, the metal potassium block is manually rolled to a metal sheet with a certain thickness by means of a metal aluminum rod;

[0062] Step 5, cutting the rolled metal sheet into metal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com